-

Posts

935 -

Joined

-

Last visited

-

Days Won

42

Content Type

Profiles

Forums

Events

Gallery

Community Map

Posts posted by MartyNZ

-

-

I can pry the forward UJ through openings in the shield, to pull the gbox shaft in and out almost 2mm. It needs a lot more than hand pressure.

I expect that all the suspension movement that loads the driveshaft in rapid compression/tension is all taken by the sliding joint in the middle of the shaft. It would be a disaster if the gearbox is exposed to suspension movement. I'm going to give all 3 nipples another squirt of grease to make sure.

-

2

2

-

-

On 3/19/2023 at 9:18 AM, al_roethlisberger said:

Shouldn't the nylok/nylock nut really be replaced after one use as well, especially for something that crucial, or is that overkill?

It is a good idea to replace nylock nuts after use if in a critical application, but there is an alternative.

A check for "Run On" torque can tell you if the nut locking function is still effective.

I'd call my Rear Axle nut critical, and the locking is a bit marginal, so one day...

-

1

1

-

1

1

-

-

3 hours ago, audiomick said:

...how hard is it to pull the starter motor apart?

See repair/overhaul advice here:

http://www.largiader.com/tech/valeo/

http://bmwmotorcycletech.info/boschvaleostarter.htm

http://advrider.com/index.php?threads/valeo-starter-refresh.954653/

You could also search this site for "valeo". You will be going down a well trodden path

-

1

1

-

3

3

-

-

-

-

59 minutes ago, guzzler said:

Ha ha if it's ok in CHCH weather then it'd be fine here in OZ!

Coming from CHCH originally I'm familiar with the weather.....

Cheers

Ps do you need to trickle or charge these things as if so that would be a deal breaker for me?

I ride year round here so normally battery is kept charged but since covid and work from home I've had the odd period where she's sat for a bit.

To be fair, a record cold temp at my place is only -8, and even so I'm too soft to ride in freezing weather.

The bike alternator keeps the battery charged.

The picture shows that the battery needs 20mm packing on each side to stop it rattling about.

-

1

1

-

1

1

-

-

I have a Shorai lithium battery in my bike. LiFePO4 (Lithium Iron Phosphate) is the most stable and least likely to catch fire of all the battery technologies.

For cold starting, I have never noticed any problem, but Shorai says: "If starting at 5°C, headlights on for 30 seconds will help wake the battery and increase cranking performance. If at -17°C (1°F), leave the lights on for 4~5 minutes before cranking. The result will be a better first crank, and longer battery life. If the engine fails to start on first crank, that first crank has warmed the battery, and the second attempt will be much stronger."

I've been told that it needs a "balance charge" once a year or so. It comes with a dedicated charger that plugs into a tiny 5 pin socket and manages the voltage of each cell. The charger also has a "storage" button that holds the battery at 70% for longer shelf life.

The Shorai LFX21L6-BS12 cranks my V11 well after 7 years.

LiFePO4 is also in my electric car, but outside temperature is not an issue as it has a liquid battery temperature management system.

-

3

3

-

1

1

-

-

3 hours ago, red lion said:

I'm setting the TPS and noticed that when I snap the throttle bodies and let them close, I set them at as close to 157MV as possible. But when I put pressure on the right throttle body with my hand the number would drop as much as 30MV. Should I set then by just snaping them closed or the reading I get when pressure is applied?

Did you disconnect the link rod between the two throttles? The rod-end on the RH side just pops down and off.

Check to make sure that the idle-up cam under the RH throttle is not holding the valve open.

Then you can make sure that the RH stop screw is backed off enough to allow the throttle valve to close completely. A feeler gauge helps here, as it's tricky to see.

Then you can adjust the TPS to 157mV. Patience is needed as the voltage can change as you tighten the screws.

Then you can reconnect the link, set the idle speed, and cylinder synch.

A lot of messing around before and after this critical adjustment, but it's worth it.

-

2

2

-

1

1

-

-

53 minutes ago, red lion said:

Thanks again. Do you have link's for those two maps. Is it hard to install a new map?

-

1

1

-

-

2 hours ago, Martijn851 said:

Aren't there supposed to be 2 lines coming from the tank, breather and overflow?

Some people (including me) connect both nipples with a tee to a single drain line.

-

1

1

-

1

1

-

-

You should search this site for Valpolini. There's some useful comments about these hi zoot metal reinforced gaskets, especially in relation to the timing chest cover.

I asked Valpolini in Italy directly for some gaskets, but they declined to send to me. Luckily the NZ dealer could supply. You should have less trouble being nextdoor to them.

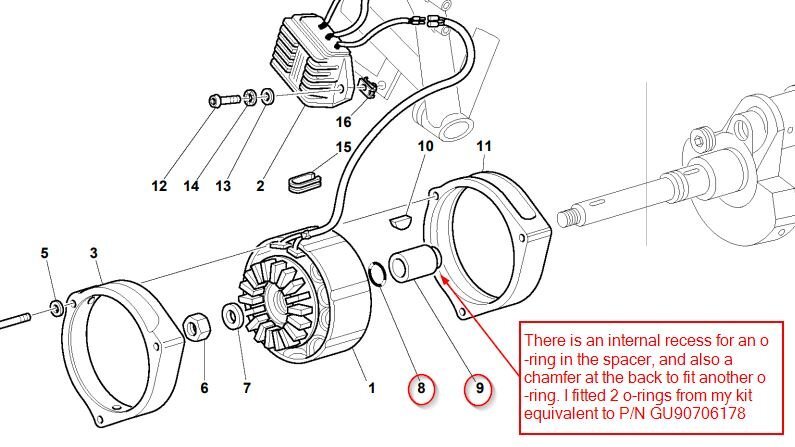

As for removing the alternator rotor, your biggest problem will be undoing the nut. Locking the crank using a big screwdriver in the bell housing porthole worked for me. Then a couple of pry bars can gently slide the rotor forward.

Conventional wisdom says keep the rotor in the stator when off the motor to reduce loss of magnetism.

-

1

1

-

1

1

-

-

-

6 hours ago, red lion said:

I hate to say this but I don't even know what a task bar is or where to find it. I don't see any windows icons.

Sometimes the best source of computer help is to ask the neighbor's kid.

-

2

2

-

-

1 hour ago, fotoguzzi said:

...I’m going to look at a Rosso Mandello later this week...

That's a great looking bike that seems to be in original condition. I think the RM has the best paint scheme of any V11. The rocker cover paint seems to fade to orange, and restoring the covers to that gorgeous red would be the only thing I would do.

As for the clutch needing replacement, @cash1000 can tell you that the RMs don't have the problems of the later single plate clutch bikes.

-

3

3

-

1

1

-

-

1 hour ago, cash1000 said:

I get what you mean. I'm thinking of possible fragile nature of single plate clutch flywheels.

You're right to be careful. An aluminum alloy flywheel is susceptible to fatigue cracking. Any stress raiser (like a scratch, drill mark, gouge or dent) can become the crack initiation point on highly stressed alloy. You have seen how perfectly your flywheel has been machined, with careful radiuses around holes. That is why it hasn't cracked, and we know that some have gone bang. Cast iron flywheels are virtually immune to fatigue, so can tolerate punch and stamp marks.

-

3

3

-

2

2

-

-

My first roadworthy bike was a Honda CB175

.

Not enough zip, so I bought an old Honda CB450. It went OK, but had a drum front brake and a friction damper in the middle of the steering head.

. It featured an under-tank ignition switch and a reserve fuel tap that we don't see on modern bikes.

. It featured an under-tank ignition switch and a reserve fuel tap that we don't see on modern bikes.

Then I got a CB450 with a disk brake.

Better, but I always thought that Moto Guzzi was the bike to have.

By the way, the pictures are not of my bikes, mine were never quite that tidy.

-

7

7

-

-

-

The shop manual I have says "Fit flywheel in reverse order to disassembly, using new bolts" with a note "Respect the timing marks". I hope that you were respectful to the timing marks

-

1

1

-

3

3

-

-

On 1/29/2005 at 8:16 AM, Skeeve said:

Bought a "used" Stucchi rack for a 2000+ Sport off Ebay for my '03 LeMans, and discovered that it apparently needs extra bracketwork to mount it.

So my question is: does anyone out there have one that they have not as yet mounted, [or even if already mounted,] that they can take pix of the supporting brackets that will be sufficiently detailed that I can cobble up my own? Alternate suggestions gladly accepted...

I think that I have the mount brackets for the Guzzi rack that Paulnaz showed. I'll go look. You can have them for the cost of postage from NZ. PM me.

However, it may be easier to contact the seller, as the brackets and bolts you need are probably still on the bike that the rack came from. The seller would have found it easier to undo 4 countersunk head bolts holding the rack to the brackets, than undo the bolts that are shared with the rear peg hangars.

See pics here https://www.v11lemans.com/forums/topic/22501-luggage-rack-what-am-i-missing/?do=findComment&comment=258679

The reason I have spare mount brackets is because I made some: https://www.v11lemans.com/forums/topic/19580-lucky-phil-extender-mod/?do=findComment&comment=212948

-

On 5/4/2023 at 10:56 AM, LaGrasta said:

After mine fell off, I threw it away and forgot all about it. Must I replace it?

If you are ever idling in traffic, then heat can rise quickly under the tank. The result is hot fuel, which is bad. Insulation on the tank lower surface, external pump, and filter are valuable to avoid vapor lick. You can get a snort during a hot start that can pop the throttle bodies off. Don't ask how I know this.

If you always go fast, then you don't need to replace it.

-

2

2

-

-

49 minutes ago, Speedfrog said:

That looks like a good replacement for the original heat shield. Does it have a product name/brand and where did you source it?

I would search for "Heat Protection Film Self-adhesive Auto 1.4 mm Insulation" or similar. Aliexpress sells this: Car Heat Protection Film Fireproof Heat Insulation Mat Self-adhesive Aluminum Foil Glass Fiber High Temperature Resistant Cloth - Sound & Heat Insulation Cotton - AliExpress

Or follow audiomick's advice above.

-

3

3

-

-

3 hours ago, Speedfrog said:

Yes, the heat shield is present on the long tanks as well and like you said, it has a tendency to loose adhesion and come off at the edges. I’d actually be curious to know what kind of glue anyone has used to stick it back on and how well it held up.

And if anyone has ever replaced it, what type of material was used for it.

I got some aluminium foil faced self-adhesive fiberglass insulation sheet that is 1.5mm thick.

It looks like it will work well, as it has some insulation against both convection heat and infra-red radiation, and if I can make a 1 piece panel, it should stay in place, and continue to do its job even if the adhesive fails.

-

1

1

-

1

1

-

-

-

On 4/21/2023 at 8:09 AM, Cold Desert Rat said:

left came on the bike, stainless steel

right came off 1100 sport

Will one keep the exhaust valve cooler by a significant degree? (degree, get it

)

)

I doubt the difference is significant but it's interesting

An interesting thought, but in my opinion, the change in clamp type is more likely to be a cost of manufacture decision, and also a styling choice.

The earlier finned clamp has more surface area to lose heat, but since it is clamping the exhaust pipe to the head with an insulating ceramic filled gasket in between, almost all the heat lost by the clamp comes from the pipe. I think that the exhaust valve temp will be unchanged by the clamp type.

-

2

2

-

Rear brake lever removal...

in Technical Topics

Posted

The piston rod can fall out, but if no brake fluid follows, then just put it back. If fluid comes out then you have a different problem