-

Posts

934 -

Joined

-

Last visited

-

Days Won

42

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by MartyNZ

-

Sounds like my experience. I thought the filter material was breaking up. https://www.v11lemans.com/forums/topic/20282-fuel-injector-cleaner-yea-or-nea/?do=findComment&comment=229694

-

I wonder if some 2-stroke oil would reduce corrosion in those parts? It could leave a protective film behind as fuel evaporates. I tried this on two daughter's cars when they went overseas for a year, with no ill effects

-

I'd try fitting the left pivot pin from the inside, so that the pin swages the damaged outer few threads into line. After that, wind that LH pin out enough to fit the swingarm and RH pin. If you use a tap to recut the threads, you risk having a loose pin if you don't use the correct tolerance tap.

-

There's no quick answer to your questions, but you should consider that pressure hose (& probably pump) designed for total immersion in fuel are different from external components. Mounting a pump inside a tank will be tricky if the tank is not designed for it. Power and fuel passthroughs across the tank floor need a fuel tight design. Also the tanks you mentioned were made for a conventional frame, not a spine frame, so fit could be a challenge.

-

I think it is important to make the grounding of the regulator to the frame/engine/battery perfect.

-

If someone has a cracked gearbox, a guy in UK is virtually giving away the casing. Moto Guzzi V11 Gearbox Casing, New Old Stock | eBay

-

Electrical connections will degrade over time, and any 12v system is vulnerable to increased resistance from corrosion. Oxygen and Humidity cause this. Imagine how much more trouble a vintage 6v system was. I'd disconnect the ground lead to the gearbox first. Get clean shiny metal to metal faces, re-assembled with grease. Battery terminals next. A voltage drop to 4.5v means a bad battery &/or bad connections.

-

Could the problem be related to Cash1000's experience? https://www.v11lemans.com/forums/index.php?/topic/21632-false-neutrals/

-

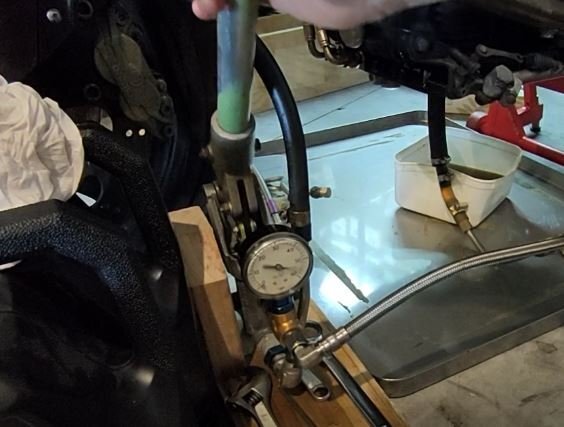

I suggest a quick troubleshooting test: take the fuel hose off the pressure regulator, point the hose into a tin, and turn on the ignition. You should hear the pump run for a few seconds, and you should see a few ccs of fuel run into the tin. If not, find out why not.

-

I've had good results with electrical switches, after cleaning as you did, by using a generous blob of grease designed for switches. Lubriplate DS-ES is one of those that is easy to get if you live in USA. It protects switches against effects of hot/cold & wet/dry cycles. https://www.lubriplate.com/Products/Grease/Multi-Purpose-Greases/DS-ES/DS-ES/

-

I see that your pump is on top of the spine. Mine is actually underneath, but I imagine that there's no functional difference. There is also a lot of hoses shown in the picture. As I understand it, the outlet from the pump goes to the filter, then injector, then other injector, then regulator return to tank. There's no other fuel pressure hoses needed.

-

Picture of the old steel fitting and the new mostly aluminium fitting. BTW, the original V11 vent is always open, so "burping" doesn't do anything.

-

I've never seen water in my bevel box, but I replaced the vent fitting anyway because: a. It could let water in. b. It was unnecesarily heavy lump of steel. c. because I could. .

-

There are some good videos here: https://www.thisoldtractor.com/moto_guzzi.html

-

There's a lot of info here: https://www.v11lemans.com/forums/index.php?/topic/20201-re-engineering-the-shift-spring/page/52/#elControls_272756_menu If the selector spring is broken, the only way to change gears I know of is to pull off the cover. Then you can slide the 4 selector forks around to get neutral. Then you turn the cam wheels to match. BTW a seeger ring is also known as circlip.

-

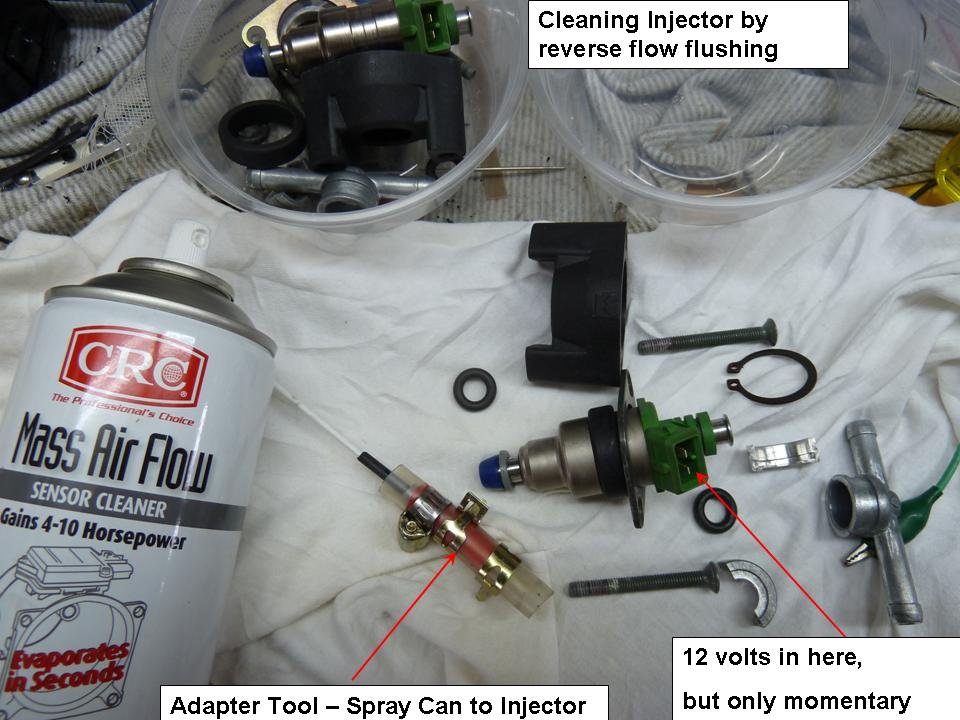

Scud posted a picture and description of a way to pressurize the injector. 5 Dec 2016. https://www.v11lemans.com/forums/index.php?/topic/18805-brand-new-scura/page/17/#elControls_215317_menu

-

How did you test the injectors? I imagine that the spray pattern would change with different pressure and different fluids. I used a spray can of mass airflow sensor cleaner and got a good spray pattern when each injector was momentarily powered. Perhaps your single stream could become a mist at normal pump pressure.

-

Light rattle in gearbox when pushing my bike.

MartyNZ replied to Walterg's topic in Technical Topics

You're right about that assembly dampening driveline shocks. The standard cush drive in the wheel is too stiff to completely do this by itself. -

https://www.thisoldtractor.com/guzzi007/sportissimo.html Your wiring diagrams and Carl Allison's are both good. Thanks to both of you for your efforts 👍

-

It sounds like the Van Gogh Alive exhibition here last year. An great show about an extraordinary artist with a tortured soul.

-

Na, it's too clean to be mine.

-

You should know that the south pole is at the top. The attached map shows this clearly. 10 million penguins can't all be wrong.

-

On my bike the injectors were held into a plastic housing with two phillips head screws. These screws were retained with locktite. Are these the screws you are asking about? Anyway, one way to remove tight screws is to use penetrating oil and heat. Heat softens locktite. With a plastic housing, heat conduction is poor, so heating the screw head with a soldering iron may help. How hot you ask? About 60°C max should be safe. You can hold your finger on 60° for a few seconds without burning.

-

Our moderator is multi-lingual! Awesome 👍

-

I used a small hand pump to prime my bike after the sump was off for weeks. I didn't know if it had lost prime, but I thought it wouldn't do any harm. As Phil suggested, I pumped oil into the pick-up tube which pokes down into the sump screen.