-

Posts

4,538 -

Joined

-

Last visited

-

Days Won

234

Content Type

Profiles

Forums

Events

Gallery

Community Map

Posts posted by Lucky Phil

-

-

9 minutes ago, MartyNZ said:

Crankcase pressure is always more than ambient due to piston ring blowby. This is unavoidable on all piston engines unless you have an unusual feature like a scavenge pump. For this reason, crankcase pressure will build until it finds an escape path. If you block the vent going to the airbox, the pressure will build until it relieves somewhere else, possibly showing as an oil leak.

I don't think you should block that hose.

Correct you should not plug the line to the airbox or the crankcases cant vent. If you have positive CC pressure due to blow by then you have a real issue. Most of what people see coming from the PCV or CC vent is air movement due to the pumping process of the pistons. It's easier for the CC air being pumped around by the rising and falling pistons to vent out the breather than follow the sometimes convoluted internal route to the underside of the rising piston. Sometimes CC pressure can briefly go to zero or a little below on a wet sump engine that uses a reed valve in the breather such as Ducati twins have for years and years. As the CC air is expelled out the breather any slight pressure is vented and the reed valve then closes and the CC pressure will go to zero or fractionally below very briefly.

Phil

-

3

3

-

-

Here at last. Three litre inline 6 turbo and six speed manual. Basically a BMW Z4 with Toyota hardtop body. Two seats only and low.

-

5

5

-

-

You might want to look at the year model in the heading.

Phil

-

1

1

-

-

6 hours ago, gstallons said:

Energizing the fuel pump will not cycle the injectors .

Every time you turn on the ignition and power the ECU it activates the fuel pump for a prime period and also puts a shot of fuel down the intakes.

Same as every time you start the bike no matter what the engine temp you get 4000 engine revolutions of the start enrichment map.

Phil

-

1

1

-

-

4 hours ago, audiomick said:

As far as that goes, I read something to the same effect in the German forum. It was regarding a Nevada 750, and I had problems connecting the Breva 750 (same motor and ECU...).

The problem was, I could connect to the Breva following the Guzzidiag prompts for "ignition on" etc., but when I started the motor, the connection broke off.

Following reading the suggestion to start the motor first, I thought about it a bit, and decided to try "start motor" at the point where Guzzidiag says "ignition on". That worked.

That means: connect everything up. Start Guzzidiag. Select "connect" ("verbinden") from the menu. You get a pop-up that says "turn on ignition" or something to that effect.

Rather than just turning on the ignition at that point, start the motor and then click on "OK".

That worked with the Breva. I expect fully that it would work with a V11 that has the same problem (connection breaks off when the motor is started), but can't check that because the connection with my V11 works without any problems.

And if this problem shows up, and this solution works, spare a thought as to why the voltage drops during starting enough to break the connection. I haven't sorted that with the Breva yet, but I reckon there is something fishy there...

Bad battery/battery connections. Voltage sag during start.

Phil

-

1

1

-

-

On 6/15/2023 at 3:08 AM, PJPR01 said:

Make sure the ignition is on AND the fuel pump switch is on, or Guzzidiag will not connect.

By fuel pump switch I assume you mean the "kill switch"? I always pull the fuel pump fuse to eliminate the shot of fuel that goes down the intake ports every time you cycle the ignition switch.

Phil

-

1

1

-

2

2

-

-

3 hours ago, Gmc28 said:

Decided for now to strip it then clear coat the aluminum (cast) piece, as I wasn’t loving the idea of layers of primer and paint, and all the exposed transition edges. So far it’s looking ok, way better than the damaged aluminum-colored paint that I got it with, but will be easy to pull and do again if I don’t like how it looks on the bike.

Got a little carried away with the 600 grit in a couple spots, and didn’t want to buff it any more and get it any shinier, as too much shine is what will make it not look right on the bike. We’ll see.

And Stein Dinse delivered the new stainless nut today. So re-assembly can commence this weekend, and maybe get ‘er runnin finally, soon.

Green Scotchbrite gives the best satin finish to aluminium.

-

2

2

-

-

Yes it's a lovely place in it's own right. I did 2 TT's back in the mid 80's and my wife is quite keen to do one herself but after seeing a docco about the TT fortnight a few years ago I'm not super keen to return. These days you need to book 3 years in advance and it was fairly crowded back in the 80's but now it's wall to wall people during TT week/fortnight. A case of popularity ruining something that was really good. Seems popularity often has this impact on many endeavours the more I think of it. Climbing Everest is a complete joke these days as a classic example.

Phil

-

2

2

-

-

15 hours ago, innesa said:

IMG_8350.HEICHello V11 Brains Trust

I have a 2001 V11 LM, that appears to be haemorrhaging oil from the oil cooler.

I am wondering if there is any issue with simply disconnecting the hoses at the sump, replacing them with sump plugs/ similar, & binning the oil cooler altogether?

A mate has a Griso, & he decommissioned that bike's oil cooler, however, replaced the hoses with a single much shorter hose, between the two sump ingress/ egress points due to "one-way flow".

Is there a similar issue with the LM?

Thank you

Fit a new oil cooler. I bought one of these years ago as a spare.

-

2

2

-

1

1

-

-

4 hours ago, LowRyter said:

Phil does the advantage of the 285 crank for a parallel twin over the 270 also work for 75 degree V-twin vs the 90?

Of course, no one is running a race engine on the street.

No because to achieve perfect primary balance in a 75 degree V twin you would need to offset the crank pins 30 degrees which KTM don't do in their RC8R engines for example. They still run a common crank pin but use a balance shaft to nullify the primary imbalance. The 90 degree V twin is perfect primary and secondary balance with a small rocking couple that needs no balance shaft because the RC is minor. Only commonly found engines that have perfect primary, secondary and zero RC are the inline 6 and V12.

Phil

-

4

4

-

-

And thats why a 270 degree engine like a Royal Enfield 650 twin runs a balance shaft. The British also didn't want the complexity of an ignition system for a 270 or 285 engine compared to a 360 engine.

Phil

-

1

1

-

1

1

-

-

Personally I'd like to go to the old WSB and current BSB qualifying format where the rider has one warmup lap and then a lap to put down his fastest time. Eliminates the towing bullshit, the yellow flag on the hot lap rubbish and the race grid reflects the true order of who has the outright speed. Currently you can and do have riders with 3rd and 4th row raw speed on the front two rows a lot of the time due to nothing more than getting a tow during qualifying. They then get in the way and hold up the genuinely faster rider at the race start for 5 or 6 laps and ruin his race.

Phil

-

2

2

-

1

1

-

-

2 hours ago, Weegie said:

Can I ask which ECU we're discussing here?

I'm going to reset the TPS and then do a throttle body balance on the Australia later this year, Hi Cam engine like the Daytona & 16M ECU.

Anybody care to comment if there would be any benefit in setting my TPS to 157mV per Meinolf recommendations?

15M. This isn't some magical Meinolf figure John it's the factory setting for the V11 Sport. Your bike is 150MV +- 15mv so 157 is well withing the tolerance.

Phil

-

1

1

-

-

6 hours ago, docc said:

Thanks, Lucky_Phil. I haven't been able to get my brain around the quantitative difference in the the "closer" breakpoints in the steeper part of the TPS output.

Using @Meinolf's breakpoint derivation, I can only get as far as less than about +/- 9.8 mV. But just how much narrower is the range in the lowest throttle openings . . .

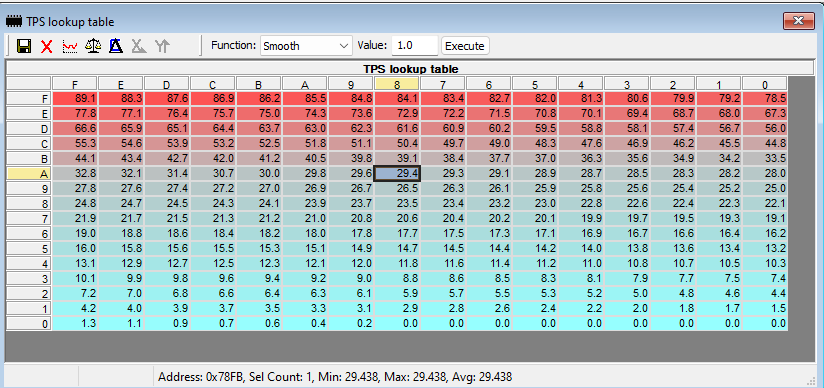

Here's another image docc, not sure if it helps. TPS in break/sampling points in degrees. On the vertical column there are break points or ecu sampling point's I guess every 2.9-3 degrees up to 29.4 degrees of throttle angle and from there to 84.1 it's now every 10-12 degrees or so. So the ecu sampling points are stacked tighter up to that 29.4 degrees so the resolution is greater I guess.

Other than that I got nothing. I'll think about it some more and try and figure it out. It may take some time, lol. Whatever it is you can still get a nice running engine without knowing the high resolution detail with some fiddling and basic tuning knowledge.

Phil

-

1

1

-

-

4 hours ago, docc said:

Me, too. Having trouble re-finding it . . .

And, to clarify, trying to discern the "steps"/break points in the original 15M V11 ECU map in millivolts sent from the TPS in the lower throttle angles . . .

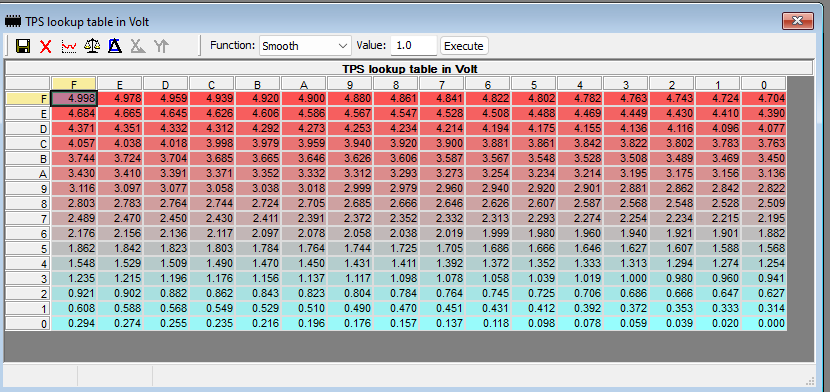

Here you go Docc. TPS lookup table in Volts. I'm thinking that what you should see with a correctly set TPS at 157MV at fully shut throttle is column 8. As a computer luddite thats what I figure. The throttle angle values are the vertical scale in hex and all the other vertical scales are for an incorrect base setting and the ecu interpolates between what it should be and what it sees. Not sure in reality. Above my "G" I'm afraid.

Phil

-

2

2

-

-

-

25 minutes ago, docc said:

I posted for the first linier v non linier graph docc. More general weber info. The V11 sport uses either the PF03 non linier or PF03c (without adjustment slots) linier does it not. From memory. My bike uses the PF09 non linier, a larger version of the PF03.

https://www.bikeboy.org/ducati2vthrottleb.html

Phil

-

58 minutes ago, audiomick said:

No doubt that was referring to the lower range of the non-linear TPS. I saw a graph somewhere. The non-linearity is not a continuous curve, but rather a steep straight line, a bend, and another less steep straight line.

Yes, I was also very suprised at how large that range is. Thinking about the numbers involved, I can see it as a pragmatic compromise within the context, but really accurate is mostly better. And lets me sleep better.

https://www.bikeboy.org/ducatitps.html

Phil

-

2

2

-

-

32 minutes ago, docc said:

Ah, yes the "non-linear" thing.

So, how many break points from 2.4º to 12.7 ?

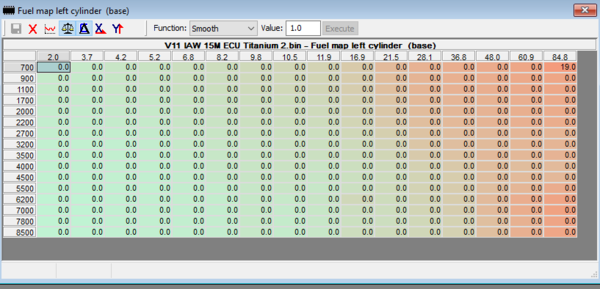

2-11.9 is 9 break points. In that TPS range to 3200 rpm there is 72 cells.

The map goes to 8500 rpm and 84.8 degrees of throttle angle.

Sorry about the break point and degrees in previous posts, those are for my bike.

Phil

-

2

2

-

-

1 minute ago, docc said:

This is very interesting stuff to the pedantic amongst us! (We may have to take this discussion to a dedicated thread as these "catch-all threads" just swallow our discussion up.

Seeing your pedantic and raising you an eyebrow:

One must consider the range as 4800 minus the 157 (4643). Assuming the 256 steps is correct (?), one step is 18.1 mV (or +/- 9). I thought I read the 7mV steps from Meinolf, but will have to try and find that reference . . .

I still maintain the Workshop Manual addendum of +/- 15 mV is suspect.

Depends on where you are in the TPS range from memory docc and what TPS you have the linier or non linier.

Also there are 256 break points but they are not distributed evenly. From 1000 rpm to 3000rpm and 2.4 degrees to 12.7 the there are more break points then the rest of the range so you have finer throttle control at smaller throttle angles.

Phil

-

1

1

-

-

1 hour ago, audiomick said:

Another thought regarding fixing the throttle valve down with cable ties, or pushing it shut to do the "base level" measurement:

I observed today that pushing the throttle shut changed the measured voltage by about 4 mV. On the basis of that, I reckon there is no point in taking the extra effort to tie or push it shut. Make sure it is clean and unhindered, let it snap shut a couple of times, and do the measurement. Any further measures just wont make a significant difference.

It's not about the accuracy predominantly Mick it's about the consistency and the fact that with the throttle blades gently cable tied shut you have one less thing to think about and check and also the blades don't try and follow the TPS as you adjust it.

Phil

-

2

2

-

-

question is is it an original flywheel or has it been replaced with a RAM unit at some time.

Phil

-

Single plater.

Phil

-

1

1

-

-

That sounds like a twin plate clutch to me. My single plater is quiet engaged and a slight high pitched rattle (more of a swishing sound) when disengaged. My old twin plater sounded like yours does. Check the flywheel access hole and see if it's been change to a twin plater by the PO. BTW if you snap the clutch lever in and out of engagement at idle once it'll reduce the rattle by about 75% each time.

The RAM single plater is the best individual mod you can do to a Guzzi big twin.

Phil

-

4

4

-

2

2

-

Andreani upgrades for V11 OEM Marzocchi forks

in Technical Topics

Posted

I have bad experiences with Andreani cartridges. I ordered a set for my later v11 Sport/Le Mans 43mm forks as the carts were listed by Andreani as fitting 2001-2006 bikes but when I received them the fork caps were the wrong dia and thread pitch. I emailed Andreani and their after sales support was non existent. Zero interest in helping me. Never again will I deal with them. The cartridges themselves look nothing special and were 20mm as opposed to the std Marzocchi 25mm dia. Six months after I told them their model listings for the V11 Sport/Le Mans series was WRONG the Andreani site listings were still the same! Took me 6 months to get a refund on my money and I lost 100 dollars in the process.

Do these cap threads look like they are the same thread pitch and dia? As usual you find out the true quality of a product/business when things go wrong. In Andreanis case they failed that test miserably.