werks

Members-

Posts

13 -

Joined

-

Last visited

-

Days Won

2

werks last won the day on January 14 2018

werks had the most liked content!

Profile Information

-

My bike(s)

v11 lemans, others

Recent Profile Visitors

742 profile views

werks's Achievements

Rookie (1/5)

10

Reputation

-

Don't do it man...hang on to it!!!

- 11 replies

-

- 3

-

-

-

- v11

- v11 lemans

-

(and 1 more)

Tagged with:

-

Is the xl still available? stephenpatemoto@gmail.com

-

Count me in please stephenpatemoto@gmail.com

-

Hi, Stephen.. it's been a while. Hey Chuck! I miss seeing ya, Man! I didn't make any extras except a couple for Scud and one for me. I made several of different thickness and preload. Once I came up with what I thought was best, I gave all the rest the flotation test per Dave Richardson. I understand. Regarding the coil spring. Footgoose has done it, of course, although early on he mentioned some difficulty shifting and thinks it "may" need a stronger spring. What it does do, however, is introduce some variables in tension during the fore and aft travel of the pawl. Lucky Phil alluded to that, and agreed the torsion spring seems to be the way to go. Not to mention.. it would be very difficult to design a kit that would work for everyone, no matter their skill level, to install. Exactly my thoughts. As I know you know... there are reasons that coil springs are not commonly used inside engines and transmissions, even in a dry shift quadrent setups. Certainly, the pawl spring breakage is real. I know Mark at MG Classics and Todd at Guzzi Tech pretty well, and they have changed a boat load of them. Scud is a V11S whisperer, and from memory broke 3 in different bikes at about 10000 miles. Thanks, Stephen. As far as I *know* Guzzi didn't have a reliability lab at that time. Dr. John mentioned putting a front wheel against the wall, dropping the clutch, and seeing what broke when he was working at the factory. (Greg Fields V twins book)I gave it my best shot. There will be a *lot* of crow to eat if they start breaking in service, too.. but I'm reasonably sure we have the answer. No. No way. No crow. You have done the work, no one else has, to the best of my knowledge...and anyone who critisises the effort is wrong to do so. As for people asking if I was referring to them with my comments... I am talking about the internet in general... I don't follow posts here much. As for the coil spring... If it is working... good on ya... that’s what matters. I’m not going to go into an design or engineering lecture. I hope it works out.

-

I'd be more concered Chuck with how the nylon would react to transmission fluid over time. Ciao I use them in many applications. Zero issues with oil or transmission fluids.

-

Woulda been helpful, right Chuck? I had a customer that became... in my opinion, ridiculously obsessed that his v11 cafe sport spring was *going to break* because of allllllllllllll the wrong assumptions and frankly... ignorant speculation and assumptions over the internet about the “certain failure” of these springs. So, I ordered another “bad” spring...took the whole assembly apart, and approached it’s replacement like I would anything....I basically measured and polished and precision fit everything that was reasonable or relevant. I remember putting a hardened shim washer or two somewhere (this was nearly ten years ago so my memory is mot 100%). The thing worked even better than to start and ladt I checked he was up around 55-60k miles with zero issues there. I also had a neighboring shop give me a broken spring out of another bike... and took the good extracted cafe sport spring and the other broken one to a shop that does heat treating work for me. They’re opinion after breaking one and looking at the striation in the metal is that the springs likely suffered from a form of embrittlement either thru less than ideal manufacturing (the formng and /or heat treating), incorrect specificaton and or poor assembly or assembly specifications / QC. They did a hardness test of the wire, and it was too hard for the application, typically speaking, as these are commonly used. One of several conclusions we came to is that, as a result, if it was over extending, it would also mal-positioning and interfere with other compinents, further compromising it thru a nick/ stress riser, etc. That, combined with inherent vibration within the application meant there were *potentially* a few points of compromise, premature fatigue or possible failure. Or..... not. I am not telling you anything you guys probably do not already know. However... I noticed there is a lot of bad assumptions being made by people who are not subject matter experts, or just like to make snarky comments about Guzzis etc. That is a real shame. This is not that big a deal. The other thing I have personally witnessed many many times with people (Guzzi or otherwise) that have repeated failures of a component.... (specifically these type of shift springs....or clutches, or.... whatever), is that that beat their shit out of their machines in some way. Each time, I would go ride with the person having the repeat failures,.. and EVERY TIME.... I immediately understood why. One guy had broken five return springs on his BMW /5. He shifted like he was a drunken irish clog dancer... kicking the damn pedal up and down. It was ridiculous. Another guy kept burning out Sport 1100 clutches. Seven, In three years to be exact. This guy loved to go online and shit talk how bad a machines Guzzis were. He was a robotics engineer. He treated his Sport like he was drag racing... slipping and dropping the clutch excessively in every direction, like it was a japanese modern multiplate slipper clutch and hecwas racing some bastard form if dirt track moto gp. He had very unrealistic, misguided expectation of the Guzzis design. He was an educated man... but still blamed the marque, rather than himself.... of course. Chuck.... what you have done here is terriffic. I can say with an acceptable degree of certainty that you have designed and now developed a part with far more application considerations and actual testing than the Guzzi engineers ever had done. That is not a slight to them, what-so-ever. It is all too likely tgat Guzzis supplier screwed up some specification... and these bikes *were* built at a time when the assembly controls were inconsistent,( to be grossly understated about it), due to multiple factors....company mis / disorganization, labor issues etc etc. I just spent hours going thru every post... and enjoyed it immensely. (I have to say... that coil spring modification is very unwise for multiple reasons.... but an interesting effort). I have to do this kind of thing for Vincents pretty constantly. It is a LOT of work that no one really is ever able to appriciate or even have a frame of reference for. I have had 0.000 spring failures on my v11LeMans. Frankly, I don’t anticipate one either. BUT.... I dont need to have someone field test it to know that you’ve already made a better mousetrap. So... Please count me in for a batch of them. Even ones from your bench rather than whatever manufacturer does is fine for me. Let me know how much per spring, and how to get you the money... and then I can determine the number. Maybe ten? I am just so impressed that someone actually DID something logical to help put all this spring nonsense to a rest in some way, and help support those having problems... I just want to support that. Maybe someday I’ll actually need one. Stephen Pate stephenpatemoto@gmail.com

-

There a go... Agree with all that. You'd be surprised how many people don't even lubricate the seal before they torque them down. "My sport is stored year round with temperature and humidity control. On a Persian rug. With soft music playing in the background" You Sir.... Have got life figured out. Except the soft music. My Lemans likes AC/DC and Hendrix, and will not tolerate soft anything.

- 8 replies

-

- Oil filter

- tools

-

(and 1 more)

Tagged with:

-

Installed properly, the clamp on the filter is unnecessary.

- 8 replies

-

- 1

-

-

- Oil filter

- tools

-

(and 1 more)

Tagged with:

-

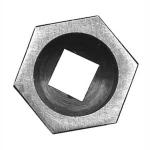

http://www.tooldiscounter.com/ItemDisplay.cfm?lookup=SIRVA6011&source=froogle&kw=SIRVA6011 Easy to use, and carry. I'm turning my down on the lathe to be even lower profile for transport. Stephen.

- 8 replies

-

- Oil filter

- tools

-

(and 1 more)

Tagged with:

-

That's fairly horrible. At least the bodywork is.