-

Posts

282 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Events

Gallery

Community Map

Posts posted by motoguzznix

-

-

Jackal rubbers do not fit the V11!

-

1

1

-

-

Hi Jim

Valve adjustment is done, me too I prefer the 15/20 values for the V11. TPS adjustment with throttle synchronisation is next step. Maybe that will already cure the symptoms.

If not check CO value at the popping rpm. Supposedly very lean.

The ECU has a CO trim that can be adjusted using the Guzzidiag software. Check for this in the forum - it is cheap to get the necessary parts and easy to use.

-

1

1

-

-

I had the case when I torqued these12.9 screws with 43Nm the joint was still a loose fit on the gearbox output shaft.

To overcome this I cut the slot in the yoke some mm deeper. Works....

The flat headed screws are useless - they won't stand the torque to be applied.

-

2

2

-

-

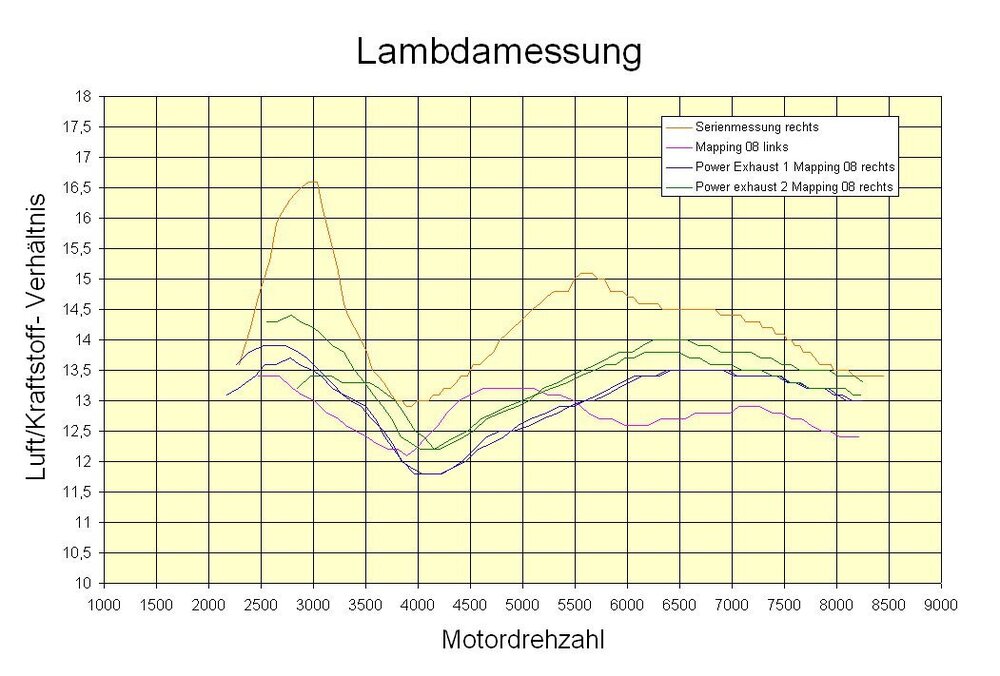

Look at the attached graph of my lambda measurements on my 2000 V11. The uppermost line is the stock bike (stock exhaust) at WOT. AFR at 2700 rpm goes leaner than 16 which is way to lean for a V11.

When putting on a different exhaust, the situation may worsen easily.

The lines below show the effect of my first changes on the fuel map.

-

The single pin calipers are an older design and were replaced by the dual pin calipers. All V11 are the later ones, 1100Sport, Centauro and Calis prior to 2000use the older single pins.

A good choice for organic brake pads are the TRW Lucas MCB 683 without any suffix. I used them on various bikes and they always performed well. They wear slightly faster than sintered pads but contribute to disc life.

-

On 2/7/2023 at 12:39 PM, Pressureangle said:

Correct of course, but you've missed the point. It's not the engine we're concerned with, but the handlebars and footpegs and seat.

Ok, I understand your point and I agree.

My point was related to an engine that suffered of very severe engine vibrations that could not be cured by simple anti vibrational measures. Disassembling a motor is in most instances not an option when vibrations are evident. When assembling an engine with different pistons, rods and other tuning parts, the engine is usually out of the frame and the necessary parts to balance the engine are at hand.

The advantage of an engine balanced correctly is that vibrations must not be killed because they are not generated. If balancing the engine with the correct counterweight the vibrations generated are reduced to a theoretical minimum. When the level of vibrations is low or zero, parts will not resonate because they will not get stimulated.

And there is an other big issue cured by balancing: The vibrations created by the rotating and oscillating engine parts will be transmitted via the big end and main bearings, engine mounts into the frame, handlebars, footpegs and so on. So the bearings must handle additionnal forces when the engine ist not balanced correctly. This contributes to additionnal wear in the bearings and reduced service life. These forces get higher when rpm climbs. If high rpms are a goal, balancing is important.

-

1

1

-

-

18 hours ago, Joe said:

I owned a 2001 Silver V11 Sport new that I later added a Fast by Ferracci drop in pistons, FBF Power Commander w a custom map made to make peak horsepower, lastly FBF carbon exhausts. We also created a vibration machine that even with Throttle Meister heavy bar end weights couldn't resolve, leaving you with numbness on demand.

Hey Joe

From my point of view this engine was missing some measures necessary:

The hi comp pistons with a CR of 11:1 are over the top for a V11 in my opinion. The piston dome is higher, thus the compression chamber shape gets worse. And note: The big valve heads like in the V11 still have the worst combustion chamber shape of all Guzzi heads. The best solution to overcome this problem ist installing twin spark ignition which shortens the time to burn the air/fuel mixture. The Guzzi engineers invented this when they created the Breva engine.

This leads us to the ignition map: The V11 has extremely high ignition advance figures. At max rpm and WOT the advance is 44° which works only with the low VE the standard engine generates. When you increase the pressure in the combustion chamber by either aspirating more air into or a higher CR, the engine burns the mixture faster which allows us to reduce iginition adance.

The same goes for the twin spark: the mixture burns faster, ignition avance can be reduced.

A PC can only address the mixture, with an appropriate ignition map your engine would have beeen performing a lot better, be it power or vibration level.

The graph below shows the influence of ignition advance on power and torque on my own V11. The only difference between the two measurements is for the red curve ignition advance was reduced by 3° at full throttle which indicates the stock advance figures were over the top.

-

1

1

-

-

14 hours ago, Pressureangle said:

In my (now Son's) '85 LeMans, I installed Carrillo rods, cut the heads .010", and installed a Web 85b cam.

It's dead smooth compared to stock, at any RPM.

The lesson here, of which I have many examples, is that 'engine balance' and especially 'factory balance' are theoretical models coupled with testing to achieve a target RPM at which the engine is smoothest. If you ride outside the bell curve of balance, or you like the higher and and your particular engine tolerance stacks to balance at a slightly lower RPM you get more buzz.Sorry when I s´disagree in this respect,

Balancing has no sweet spot. When your tire is out of balance, it will get worse the faster you drive. The same goes for the piston/rod/crank balance.

Best example is your engine mentioned above: dead smooth at any rpm. If your engine was not balanced, then you were lucky to get the right parts together. The carillos are a lot lighter at the bottom end than standard rods which may contribute to the smooth engine.

-

Hi all

Some of the red frame V11s had an issue with severe engine vibrations. There is no way to cure that with foam or silicone grips or bar end weights.

I remember a road test in an italian motorcycle magazine by Alan Cathcart with a very early V11 that mentioned also the engine vibrations.

My very much beloved black V11 from 2000 was also one of the bikes affected. I was happy with the bike until I changed bike with a friend of mine driving a Lemans3. He was shocked by the amount of vibrations generated by the engine. Me too experienced how smooth the old Lemans engine was running.

The red frame V11s suffered of two factory rework issues: one related to the gearbox, the other to the conrods. For my chassis number only the gearox rework was listed and carried out by my fellow dealer. I suggest my bike suffered also the rod issue. Guzzi mentioned the rods were prone to crack on bikes frequently revved near the engine rpm limit.

My conclusion was the rods on the affected bikes were too heavy and so the engine balance was out of spec. For my bike there was nothing to be had from Guzzi, so I decided to balance the crankshaft myself. At 9k km I dismounted the engine from the frame and teared it down to bits. I weighed all the parts necessary, calculated the master weight and put it on the crank pin using lead sheet stripes. The balancing was carried out only statically on a balancer very similar to tools used for tire balancing. My crankshaft needed removing of material mainly in the area of the crank pin.

When the engine was completed and reinstalled, the running behavior was absolutely different: The severe vibrations were gone, the engine was almost smooth as the LM3 engine.

-

3

3

-

-

Weegie

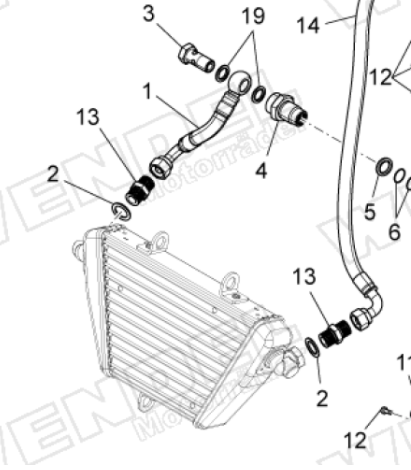

Did you ever have a look to the oil cooler of the Norge 8V?

This is designed to work at the lower front of the fairing which could fit perfectly your Australia.

-

1

1

-

1

1

-

-

On 7/20/2021 at 9:16 PM, Pressureangle said:

I'm 99% in accord with this, *but* there is that 1%. I've attached a photo of a Camshaft for illustration. On a big block Guzzi, all four cam lobes are on the same side of the cam. A compressed valve spring returns all of the energy input on the opening ramp back into the rotation of the camshaft on the closing ramp, minus heat losses through friction; on the ramps where a valve is closing at the same time another begins to open, the opening ramp 'catches' the closing rotational forces and *probably* cancels them. On the other side of the cam, though, there are two closing ramps with no opposing opening ramps to prevent them rotating the camshaft into whatever slack there may be in the chain, or perhaps overcoming the weak stock tensioner. Worse, they close at the same time doubling the effect. I believe that's the source of the spark scatter at idle, and I won't assert but remain open to the possibility that the ~3k rpm dip may be some function of chain slack and resonant property stack in the components.

I also agree that this is the reason for the spark scatter at idle. The frontmost cam on the shaft is the last one to be active and therefore can rotate "back" when the follower is over the nose of the lobe. In fact it does not rotate back but shaft rotation ist slower before and faster after passing the top of the lobe. On old engines driven for a long time with chain slack, you can see a flat on the front cam...

This is not just a theory, it can be proven - install a valtec type chain tensioner and check spark scatter with a timing light - you will see it disappeared compared with the slacky stock tensioner.

-

3

3

-

1

1

-

-

On 1/28/2021 at 7:34 AM, footgoose said:

I know what you're saying, I've thought the same. Personally the gearbox wouldn't hold me back from buying. I would want the USD forks though. All depends on your fantasy. If yer askin I'd wait for a deal on the later model.

In my experiance, the 1100 Sport M1R fork is a better fork than all the different USD forks in the V11 - except the Öhlins units.

-

2

2

-

1

1

-

-

Hello

In a carb 1100 sport the 6 speed box is more difficult to install. The front subframe is welded onto the frame, so you can't replace it by the V11 part. Also the bottom subframe needs to be replaced by the V11 part. This is the only way to get the engine/gearbox to the center. Rear drive and propshaft also need to be V11 parts. About the swing arm I am not sure of but supposedly too. For 1100ie and Centauro it is possible when you get the parts togethter.

-

1

1

-

-

Hi Docc

This is not a must.

Only if Meinolf cares about and changes the identification digits on the map. There can also be loaded a substantially changed map to the ECU which is not recognisible in Guzzidiag.

-

TPS calibration electronically is not possible with the 15M ECU. Check this with a Voltmeter!

-

1

1

-

-

NF

what CO value shows your engine when running at idle? Should be at least 3.5 %.

This together with Synchronisation and TPS adjustment should cure the symptoms.

-

1

1

-

-

While adjusting the valve clearance on my workbench, the left cylinder was easy to do. The right was a different story. The adjustment screws had to be almost completely backed out to get the proper clearance, and only then did the push-rods spin freely. I had to keep readjusting the clearance on the right cylinder after turning the engine over by hand.

Wanderer

Maybe the valves got stuck in the guides. You have to pull the heads to check...

-

1

1

-

-

Worn guides but good seats? New valves and old seats?

Doing only one seldom makes sense. If this type of work is due I'd always visit a professional engine shop, never ever a Guzzi dealer with rattly equipment, dull tools and whatever more those also continuosly going out of business sheds can offer.

Professional equipment costs big money - but gives equaly big results.

Hubert

I disagree to this statement

Seats in Guzzi heads are very good material quality. That is not just my opinion, The engine shop where I bring all my heads to be reworked stated this. So it is only on rare occasions necessary to replace them. Just a slight rework to have a good seal...

Guides is a different thing. They can wear very quick. But in case of the V11 the valve stems wear quickly. I had this experiance on my own V11 - at 9000km the valve stems had a remarkable edge that you could feel with the fingernail. Another V11 Ballabio I reworked last winter suffered of very worn valve stems after 12000 km. This V11 suffered also of oil consumption. I replaced all valves and the guides on the exhausts.

And concerning the equipment of an engine shop: I prefer a good working man with old eqipment that knows what to do with it. Modern equipment is always for high volume production. The results are mostly not better than old equipment can realise.

-

If valve stems and guides are worn out severely you will hear some metallic rattle.

-

Since you have working maps fom your MyECU, you can apply them to you stock ECU with Guzzidiag. I'm not sure if the MYECU uses the same one byte (0 - 255) values, but if yes, you can use them unmodified. If the injection timing is too far off, multiply the values by a factor. Tunerpro is your friend for this.

With Guzzidiag Reader/writer and Tunerpro as map editor your 15M ECU is a completely open system.

-

1

1

-

-

Since the sump is already dismounted, you could further dismount the oil filter assembly (just 4 screws) and then drop the rod big end screws to inspect the plain bearings. Reassembling is no problem as the screws must not be replaced, Just to be sure about that.... Torque is around 65 Nm if I remember that well.

My next step would be to inspect the cam shaft axial bearing as Phil an others mentioned. Whith the Stucchi tensioner you can unscrew that small 8 mm nut and remove the tensioner with the chain and wheels in place. At this stage check also the crankshaft axial play. The front bearing can be changed from the front without further disassembling (just remove the chain sprocket) in case of wear.

If after all that the noise is still present, I would dismount the heads to check valves and guides for wear. This is very common on the V11 engines and the only weak point.

As I pointed out on my much earlier post above. wear of the valve guides is not uncommon on a V11.

Compared to the work done up to now, this is a minor issue...

-

Ok thanks for the advice. I think youre all right, slightly more noticeable when warm so could be a good start point. Previous owner mentioned he set the valves to raceco settings, not sure if that makes a difference

Also I was going to invest in the X-over pipe under the sump to replace the stock unit. Thinking the Mistral one to match the end cans. Is gutsibits in the UK the only option?

Sent from my SM-G928F using Tapatalk

Look at this http://www.v11lemans.com/forums/index.php?showtopic=11564&page=3 and scroll to the end of the page - I measured the Mistral X-over on the dyno and wouldn't use it on my bike. Except you do not care about a massive power loss above 5-6000 rpm. The Stucchi part is a much better device.

-

1

1

-

-

Those dyno runs were done with a titanium ECU and custom Power Commander map. I've since gone back to the stock ECU and a different PC map. I also replaced the modified airbox lid with a stock one. I got sick of the intake noise

.

.I recently bought the cables that are needed to use Guzzidiag. I'm going to try disconnecting the PCIII and loading a new map sometime soon. If you have a map that you're really happy with Ernst I'd love to give it a try if you want to share it.

Thanks,

Tom

Tom

I have no Maps that suit your bike as mine is much different in cam/CR/exhaust than yours.

I would ask Meinolf - he has maps that should suit your bike well, he is active in this forum, especially in the Guzzidiag compartment.

-

1

1

-

-

What causes the dip at 4k? Cam or exhaust?

I can't speak to what Ernst posted, but on the pre-2004 north American V11s the torque and power dip around 4500rpm seems to be caused by the stock exhaust crossover which doesn't have a catalytic converter like some of the later euro V11s did.

If you look at my post on page 9 in the dyno thread the first chart shows my bike with an FBF crossover. The second chart shows my bike with the stock crossover. Look at the difference between 4k and 5k rpm. The power dip went away. The only real change was the crossover. Others here have seen or felt similar results by switching to any of the aftermarket crossovers.

Tom

This is what I meant by "the power curve starts about 500 rpm sooner to rise" which makes the dip almost disappear. Rear wheel horse power does not impress me as you have the TI cans on the bike with open air box.

When looking at your specs I would enrichen the engine at full throttle to get the mixture between 12,5 and 13. This might improve HP and makes the engine run cooler. Second measure would be to reduce ignition timing at full throttle by 3 to 5 °. Timing goes up to 44° at 8500 which is too much for an engine with good volumetric efficiency. This can be done with guzzidiag.

Vibration

in Technical Topics

Posted

Hi Yam

I would also stick with the latest fuelling.

My friends Quota did not enjoy fuelling up with Diesel.

But regarding your problem: you may get some grid into with the new fuel or maybe water. Grid should remain in the fuel filter, water can go through it and cause misfires. Drain the fuel tank, renew the fuel filter and fill in clean gasoline.