rich888

Members-

Posts

98 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by rich888

-

Anyone able to post a pic of the steering damper? Specifically, the rod end fixings where it attaches to the forks. There are two dished washers. Do these go either side of the rod end ball? I assume they cup the spherical bearing? Thanks.

-

ANSWERED Horribe clutch screech as soon as I touch the clutch lever.

rich888 replied to rich888's topic in Technical Topics

And the prize goes to Shaun! Well done that man! Got the bike out today and had the screech back again. I then noticed that the lights were dimming as soon as I touched the clutch lever along with the screech.... WTF I thought and then saw the poxy starter button was stuck in. The clutch lever switch was engaging the starter! Came back on here to post the update and saw your post! -

The damper works fine as does the joint on the head of it. The joint that attaches to the forks has the play which, for some reason is only up and down. The ball isn't rattling about loose, it just seems to be able to move up and down a bit. I've found replacement rod ends from £5 upwards depending on material and bearing material so I'll just pop a new one on.

-

Nope, just up and down and the the swivel is quite loose. The MOT guy mentioned it last year but didn't fail it, so was curious about these just being like this or was it really shagged. You guys in the States don't have to worry about an annual road worthyness test right? I can just take it off for the test!

-

Yep, but seems odd for it to wear so much, unless of course it's cr@p materials and once it gets slightly loose, vibration takes care of the rest... They seem pricey for what they are (£300 list! Really???), so I'll see if I can find a new joint rather than the whole thing.

-

Not sure why but the steering damper on my V11 seems a bit loose. Too loose do you think? Does the whole unit really need to be replaced? Seems odd to have worn so much? vid

-

ANSWERED Horribe clutch screech as soon as I touch the clutch lever.

rich888 replied to rich888's topic in Technical Topics

It's been cr@p here for weeks.... This last lockdown was a complete PITA. Windy, continual rain/drizzle, just pants! The noise didn't start immediately, which is odd. It started after I got out of the drive... -

ANSWERED Horribe clutch screech as soon as I touch the clutch lever.

rich888 replied to rich888's topic in Technical Topics

Just checked the gearbox oil level and its fine. The noise has stopped now, so it could have just been dry from being laid up for a couple of months. It did sound bloody horrible though! Now I just have the 'normal' Guzzi swish swish swish, clutch sound. I'll keep an eye (ear) on it... Thanks for the info though! -

ANSWERED Horribe clutch screech as soon as I touch the clutch lever.

rich888 replied to rich888's topic in Technical Topics

Cheers Docc, Not done much spanner time on my Guzzi, its been pretty reliable until today. What needs to come off to get get access to the slave cylinder? (just been looking through a load of workshop manual PDF's and not found much about it) -

Took the V11 Sport out today for a quick run. I noticed a horrible sounding screeching noise as I pull the clutch in. Seems to start the moment I put some pressure on the lever and stops when fully pulled in. Silent when let fully out. I assume the clutch release bearing has gone bang? Happened suddenly not gradually after a month or two of sitting in the garage. It's a 2001 bike. Any ideas? Cheers.

-

2 ways to fix foggy dials. 3 if you include filling with dry nitrogen! 1: heat the glass - this doesn't require the dial to be completely airtight. 2: seal the dial so it's 100% airtight with a good desicator inside. Never tried either! Just my experience with keeping CCTV cameras fog free.

-

I had some MIVVs on my V11 and although it sounded great, I found that it was just too loud after about 20 mins in the saddle! I put some stock cans on and it's now really quiet - maybe too quiet (LOL!), but I have noticed that there seems to be a loss of power in the midrange. Is that likely to be due to the stock cans, or just coincedence? I haven't checked TPS, valves etc etc lately, so might just have drifted off tune a bit or are the stock cans really that restrictive? Cheers!

-

Looking for a pair of V11 Sport silencers in the UK.

-

Good find as Delphi Aptiv don't make the mating half (the side that is part of the TPS). I guess kojaykat got some made somewhere? In the end I broke out the whole ECU connector! (I was connecting into some other pins too though...)

- 61 replies

-

- TPS

- TPS connector

-

(and 2 more)

Tagged with:

-

I will defo check phase sensor. Anyone know how the tach signal is generated? Does the ECU generate it or does it come from the TDC sensor?

-

Sorry, missed this question! Signals for injectors comes direct from injector drive wires, T'ed off where they come out of the ECU. RPM is from the tacho wire going to the gauge and the glitchy RPM data is read from the ECU via the diagnostics port.

-

I ignore the tach and am in the process of making a nice digital dashboard! I found that the tacho gauge is very sensitive to the tacho signal drive level. Doesn't take much to stop it working. I expect that there are dry capacitors inside the gauge which are making it malfunction. At some point I will muster enough enthusiasm to get inside it and have a look... The missfire is still there, even with a different map. I am also in the process of building a data logger to capture injection times and spark timings while riding to see if I can see what casuses the missfire. I got a bit distracted by finding out that the ECU reported RPM ws glitchy, but this appears to be 'normal'.

-

Best way to find drop outs is with a digital scope. Needn't be expensive. Hantek 20mhz scope to put on a laptop is £60 here in UK. There are even cheaper scope kits. You'll see a nice plot of the TPS voltage and the knee point.

-

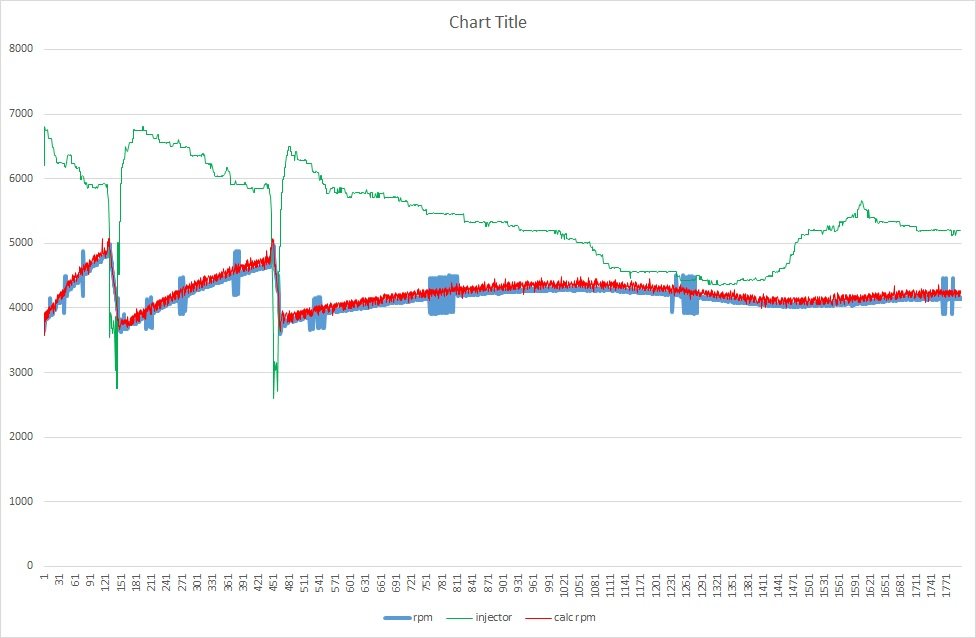

Here's a plot showing injector timing too. Looks like the glitches reported by the ECU are just errors. Doesn't seen to change fueling... This is 32 seconds long, with two gear changes. The glitches are there in blue and the red trace is the tacho signal to the rev counter. Green is injector pulse duration.

-

Yes, your right, just leaning out or richening.

-

Re hall effect TPS. You'd have to be really really sure it was impervious to stray magnetic effects. Imagine if it read full scale suddenly... I wonder if an optical encoder or resolver would be better? Both need additional electronics to generate an analog output though. We used to use 'pots' in CCTV cameras for position sensing. There wore out regularly. Then we moved to plastic track pots, as used in servo motors etc. These lasted 10 times longer. Then we moved to resolvers which last forever as there are no contact points at all. Very accurate. We tested a hall type sensor, actually a magnetic angle sensor from AMS. It worked but it wasn't completely linear and needed a calibration run to iron out the bumps. According to AMS these are used for automotive drive by wire applications. I wonder if the ECU range checks the TPS readings?

-

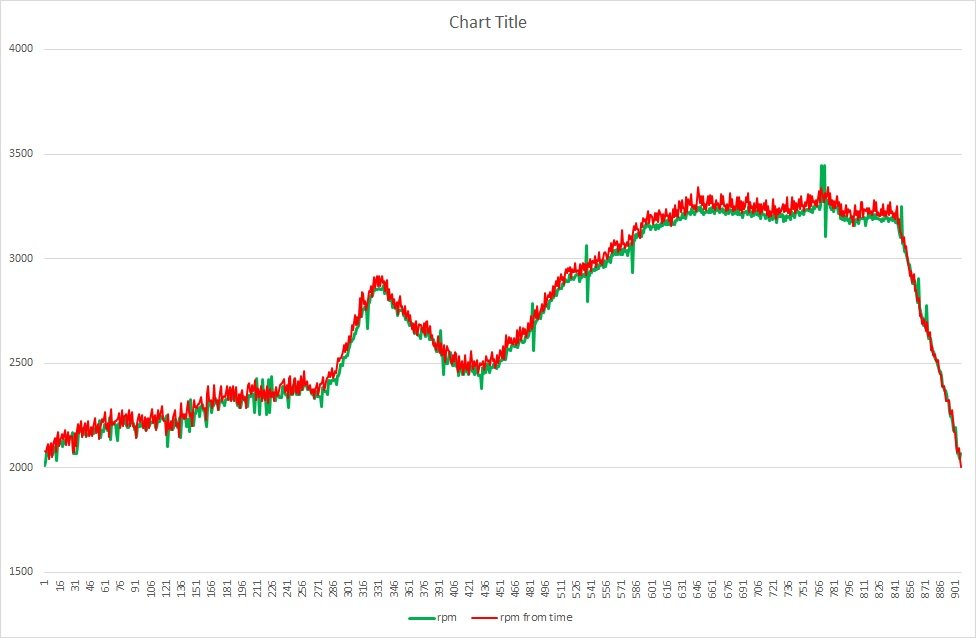

Got my datalogger to record the tacho signal directly and this is the log: The green trace is RPM reported by the ECU. The red trace is RPM calculated from the frequency of the tacho signal. I also found that the tacho signal can't handle much of a load. An extra 5mA load of the opto isolator led I'm using is enough to drop the tacho voltage down sufficiently to stop the tacho dial working. Anyway, it seems clear that the glitches reported by the ECU are not there on the Tacho signal! Need to check the RPM/TDC signal too. Question is, is the ECU reporting the glitches because its using this value of RPM in computing injector timing? I need to repeat the logging with injector timing to check...

-

Maybe there are two sensors in the one housing...

-

So there's a TDC and RPM sensor? I was looking at the service manual for a 2002 V11 LeMans and found item 34 Phase/Revolution sensor.

-

Thanks! I will stick a scope on mine today. Do you know if the Tacho signal from the ECU is derived directly from the TDC sensor or generated by the ECU software? I'll scope both and see what they look like....