rich888

-

Posts

98 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Events

Gallery

Community Map

Posts posted by rich888

-

-

-

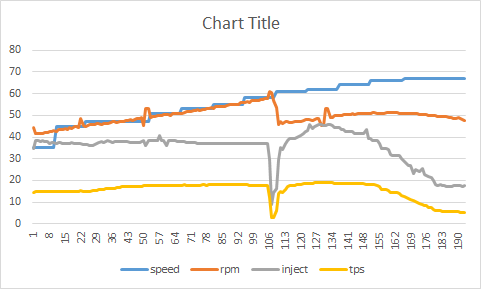

Just for interest, this is a log of a gearchange:

Speed is updated every second via GPS - hence the steps!

There are some disturbances in the injector timings but hard to say if they match RPM glitches.

The sample rate is too slow to be sure at only 15 times per second, but I have just improved that to 30 times per second, so it may show up better... When it drys up a bit outside, I'll take another plot and keep the bike in a lower gear to keep the rpms in the 5000-6000 band for longer.

I'm actually looking for the reasons for the occasional missfire / hiccup as well as the misbehaving tacho.

-

5 hours ago, MartyNZ said:

Could this show a defective RPM sensor?

Maybe.

The glitches get progressivley bigger as the RPM's go up.

I assume the ECU measures RPM from the crank sensor (TDC sensor). If it is actually reading these glitches, I would expect it to cause glitches in fueling too...

I would assume that the TDC sensor provides pulses, so don't know how it could trigger early and then late? Mabe the ECU is doing some averaging and getting it wrong!??

-

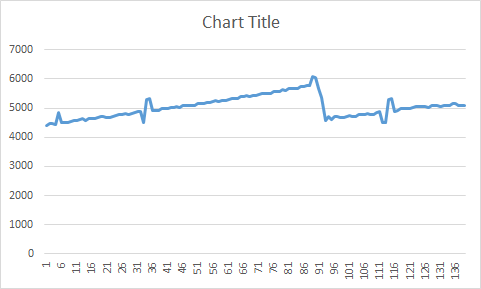

Using my homebrew datalogger, I noticed that the RPM value reported by the ECU also has glitches in:

Not sure if this helps explain the dodgy Tacho Gauge or is some other issue?

-

17 hours ago, sp838 said:

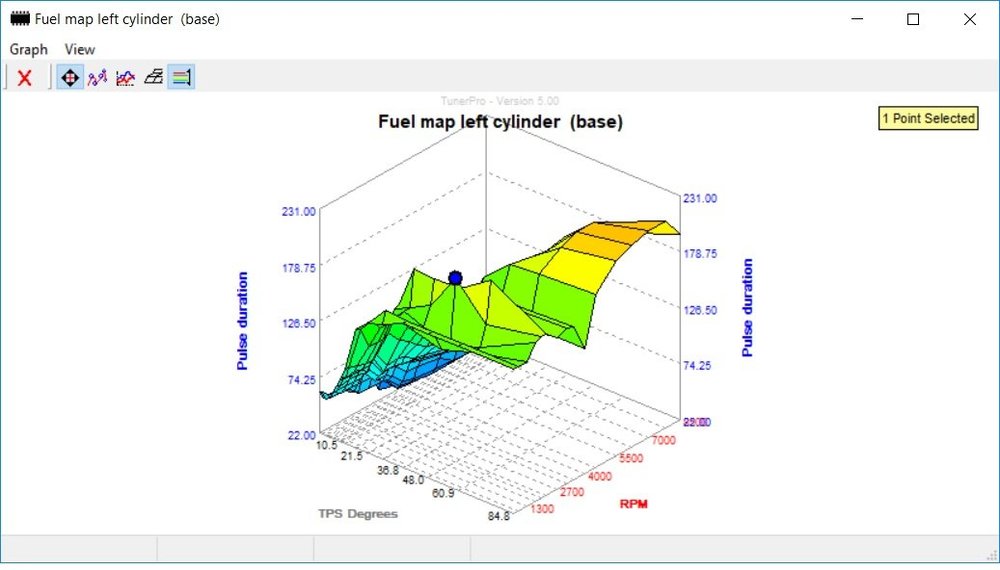

Looks like at 4000 rpm your map raises the fueling, which would lessen that trough. Similar corrections at 2000 rpm. So, money well spent

£450 to alter a few hex codes in the bin file? Good money for someone!

-

I wanted to buy some wideband lambda controller boards from wide-band.com. They are cheap at only $20 each.

"Shipping" for a board smaller than a credit card?

$93....

Can't stuff just be posted in US Mail?

I can buy stuff from China for a £ or two including 'shipping' and while it may take a couple of weeks, it always gets here...

-

-

-

Got the GPS module today. Just amazing that these things are so small and cheap... Imagine showing one to John Harrison...

Anyway, thanks to Beard over on Guzzi-Forum.De of GuzziDiag fame, for helping with a few pointers regarding the ECU and the interface.

The trick will be packaging it so that it's descrete and readable.

-

I am using a very small OLED display which is big enough for 2 digital readouts and 1 bar graph or dial. These can be any of the data items available from the ECU. These screens are very cheap and very clear even though they are less than an inch across. Could have 2 or 3 of these mounted together...

I will also test a small colour TFT LCD screen which is 2.4" and has a touch screen. It should allow maybe 6 things to be displayed.

Just need to see which works best in sunlight.

Also have a tiny GPS to add, in order to get MPH and then work out current gear position.

-

1

1

-

-

-

Here's a vid showing how far out my tacho is from my homebrew all electronic tacho:

Eventually hope to replace the analog tacho with a digital version that will have serveral readouts on...

-

1

1

-

-

48 minutes ago, emry said:

AMP Superseal 1.0. Make sure you get the correct keying, there are 3 different ones if I recall.

Great thanks.

I was looking at TE interconnect superseal 1.0

I have a spare ECU that I want to plug into to develop my scangauge, instead of balancing everything on the bike the garage!

-

-

-

11 minutes ago, JBBenson said:

Clean the throttle bodies (especially upstream) thoroughly, as well as cleaning the butterfly pivots, inside and out.

I had the same problem you did, and it was a build up of gunk (probably from Ethanol in the fuel) that was not allowing the butterflies to completely close, or to close erratically.

hello JB,

I did clean a lot of black sticky stuff off the throat taking extra care around the place where the butterfly seals. Awkward without taking the TB off, but possible with a mirror and Q-tips.

Initially the butterfly was sticky. You could feel it once disconnected.

As the valve is spring loaded, it can snap back, if you let it. More realistically, if you let it gently close, it does seat at more of less the same place.

Obviously this is a position it will never normally be in due to the stop screws, so the butterfly is seating onto somewhere 'new'.

-

2 minutes ago, Meinolf said:

Hi,

and just to close this off. The 157mV I recommend as TPS base setting stems from the TPS ADC look-up table in the BIN. Guzzi, or more likely Marelli, made a stupid mistake in this table because a wrong rounding was used.

The ADC in the 15M/RC is a 8bit device, translating the (analog) voltage coming from the TPS into 256 digital steps. 5V divided by 256 equals 0,01953V. The difference between 150mV (factory recommended value) and 157mV is quite small, in fact if falls under the graininess of the ADC function (look this up in the web if interested), but why use a wrong value if the correct one is known. Cheap blueprinting, as it is.

Cheers

MeinolfOnly 8 bit! (it's a 68HC11 isn't it?)

So 19mV steps with some non-linearity thrown in!

Does the throttle position reported on GuzziDiag relate directly to the raw TPS reading or is there some rounding?

-

7 minutes ago, Meinolf said:

Hi,

the butterfly valves should be firmly seated against the throttle body. In fact the butterfly valve contact areas are slightly tapered (no sharp right angle edge) to ensure a consistent seating without hammering into the throttle body.

I've found that getting consistent (+/- 1 or 2mV) readings if using the same force to completely close the valves is standard. The variations you mention might well be due to worn out throttle shaft bearing(s). I've used standard bushings to replace the original ones if the play became to large.

Cheers

MeinolfYes could be that. I cannot feel any play, but the TPS is very sensitive. It picks up tiny movements.

The bike has 30,000 miles on the clock.

-

Anyone know the original manufacturer of the ECU plug, harness side? IAW15M ECU.

I assume Aptiv/Delphi of some type?

-

3 minutes ago, Meinolf said:

Hi,

your reasoning is quite correct. However, there's a lot of combined play in different bearings. And only with zero play would setting the connecting rod clash with the throttle stop screw setting. Taking a close look at the mechanics will make this more obvious.

Cheers

MeinolfOK Thanks Meinolf!

I thought I was going mad!

I will using both stop screws for idle and the white knob for 3k, which should tune out backlash/slack in the linkages...

One thing I did notice while setting TPS, the fully closed position with no throttle stop is quite variable.

For example, if you let the trottle close gently, the TPS may read 180mV. If you let the trottle snap shut, the TPS may read 150mV.

Trying to get consistant 157mV is impossible as the closed position is variable depending on how much force closes it.

I thought this may be due to dirt and soot inside the TB so I cleaned it. The bore and the edges of the butterfly. It is still showing some inconsistancy.

-

Hello again,

I understand what Meinolf is saying.

So to clarify, (and ignoring GuzziMoto as instructed

)

)

You set idle synch with the connecting rod disconnected. Using the throttle stop screws ONLY.

You then adjust and connect the rod ensuring that both TB's are still on their stops.

Then set the 3k balance with the adjuster knob.

What I do not understand is if the two TB's are at rest on their stops, the rod is set to allow this and then rod length is adjusted to balance at 3k, one of the TB's must move off it's stop when returned to the idle position.

Am I being thick? I am I missing a neuance of the connecting rod?

-

I've been looking around at TB balancing/synching.

There appears to be a few schools of thought about setting idle balance.

I was advised by Meinolf, after loading his bin file, that both air bleeds should be closed and that I should idle synch using both throttle stops.

This is obviously counter to most of the posts that say only use one throttle stop to set idle speed, or some that say to use the air bleed screws.

I am thinking that, after setting TPS, closing both air bleeds, I leave the throttle link bar disconnected and set the idle balance with just the throttle stops.

Then reconnect the throttle link bar making sure it's adjusted to keep the idle in balance.

Now set 3k rpm balance with the white knob.

I can't quite see how that won't change the idle balance?

Am I missing something?

-

3 minutes ago, Meinolf said:

-

By idle screw you mean one of the throttle stop scews?

Don't use this procedure with my (or any) BIN. The main and delta fuel values are synchronized at every breakpoint. If you change the idle throttle of one throttle only then you lost the synchronization between the TPS breakpoints. Sync'ing in idle is the only way to match the TPS breakpoints. And it's especially important in the low load area because the TPS breakpoints are spaced so tightly. Getting this and the base line setting of 157mV right are the single most important steps.

The V11 TPS placement on the right side is rather unfortunate because wear-prone connections introduce play.

Cheers

MeinolfYes, I have only set the left throttle stop as described in the tune up posts.

Is there a detailed proceedure for synching both throttle stops I can read?

I have a dual vaccuum gauge and gear to read TPS etc.

-

Just now, Meinolf said:

a BIN is always the complete software, both program code and parameters.

Cheers

MeinolfInteresting! There's not much software in these ECU's !!!!

Does your bin file have any software changes or is it purely data table changes?

.jpg.462acab3e04e3fd3f72edab2516f7647.jpg)

.thumb.jpg.34cfbea987a51bf4241c876123e6391e.jpg)

.thumb.jpg.331a3907bb6f6a2d049bb0c6603bd126.jpg)

Veglia rev counter showing half revs

in Technical Topics

Posted

Not thought of that!

It's not going to be easy to verify the TDC sensor operation, will probably have to datalog the pulse timing from it directly, together with the ECU RPM values.