guzziart

-

Posts

287 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Events

Gallery

Community Map

Posts posted by guzziart

-

-

Yeah, I reached out to Electrosport for clarification on the electrical connection compatibility. I'm looking at their ESG814 Stator & ESR515 Regulator/rectifier....the stator has a sqare plug with spade connectors & their reg/rect has an SAE connector & 3 male pin connectors so, how does one plug into the other??. I really don't want to be splicing/cobbling stuff together, would prefer a "plug & play" set-up. Hopefully I'll hear back from them today or tomorrow...even though I'm not in a big hurry to spend money. On the plus side, Electrosport offers a one year warranty with no Odyssey battery disclaimer.

It looks like I could have some of the same connector issues with Euro Motoelectric stuff too.

-

1

1

-

-

Hi,

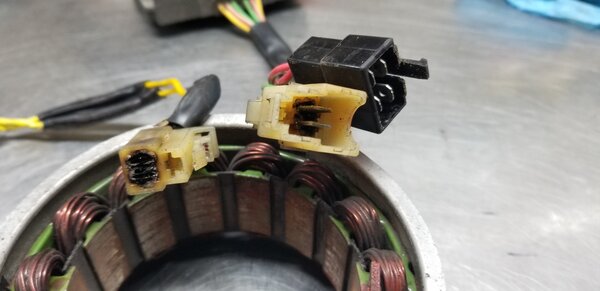

Well, I guess I wont be checking stator voltage after seeing this. I'm not gonna try splice this mess out. When I replaced the pin connectors a few years ago I noticed that the insulation had become so hot at some point in time that the insulation melted into the wire strands so I don't suspect it is any better now (lol).

FWIW, I didn't have any problem getting the exhaust header & cross-over off but the stator cover was a different matter. The cover was fastened with SS screws, the sidestand side were loose and came out easy, the other side was just the opposite...those screws were a b$#ch to get out (some evidence of electrolysis) but I was able to get a tap in there and clean out the threads afterward. IMHO, the ordeal up to this point could have been a whole lot worse. Now I have figure out whose $350-$400 reg/rec & stator to buy.

On another note, while I have the stator cover off I might try to do something with it...the battleship gray paint on it is bubbled & crappy lookin'.

Hey Docc, thanks for posting the "Posting images using Gallery", this is my first image posting here...I used your instructions.

Ok, that's all I have to report.

Thanks for reading & advising!

Art

-

1

1

-

-

Docc,

In your last post you indicated that you were interested in the Euro Motoelectric response to me about the Odyssey PC545 compatibility with the EME MG-VoltRect, see below. I appreciated the quick EME response but can't say it was very helpful. FWIW, I use a Deltran Battery Tender Jr. on ALL my stuff (Odyssey, Yuasa, Everstart & Motobat)

Art

Hi ART,

Thank you for your inquiry.

Yes, your battery may well work with our VoltRect. We have many customers that use these batteries with no problems.

The reason we caution you is because in some cases the battery and VoltRect do not communicate well with the end result being that the either the battery or VoltRect get fried. You probably use a battery tender that is specific to your battery and will not work on the older lead-acid or AGM batteries – so it’s logical that the old charging system on the bike may not work with the modern technologically advanced batteries.

Regards

Norman Schwab

1.303.526.0901

2505 W 2nd Ave | Unit # 15

Denver, CO 80219 | USA

From: guzziart

Sent: Thursday, April 7, 2022 1:39 PM

To: Info <info@euromotoelectrics.com>

Subject: MG- VoltRectHi,

I'm in the process of diagnosing a charging system (under charging) problem on my '03 Moto Guzzi V11 Lemans. While checking price & availability for regulator/rectifiers & stators, I noticed the following in the description for your MG- Volt Rect. Could you please let me know why you don't advocate use of your product with the Odyssey battery?

USE OF ODYSSEY BATTERY ( DRY CELL DESIGN) AND LITHIUM IRON BATTERY NOT RECOMMENDED OR SUPPORTED FOR WARRANTY

The reason I ask is because I have had an Odyssey PC545 battery in this bike since 2006 and replaced it in 2020 with another new PC545. I have not had a battery or charging system problem until yesterday when I noticed that the bike no longer charges at idle.

I guess where I'm going with this is, the OE charging system performed acceptably with the PC545 and with your MG-VoltRect I shouldn't expect the same results....possibly? The price of your MG-VoltRect is more appealing than the OE offering but there is no way that I would want to go back to the OE style battery the bike came with when it was new in '03.

Thank you,

Art

Northeast Ohio

-

1

1

-

-

Hi,

Thanks for the quick responses!

Tom...I looked at the Roadstercycle website, looks good! Is the OEM reg/rect on our bikes Shindengens? Also, I will try to determine if a voltage drop exists in the r/r reference circuit between the batt+ & the r/r but I'm kinda thinking a volt drop in that circuit would lead to an overcharge condition??? idk.

Docc...I grounded the reg/rect case back in 2020 when I replaced the old PC545 with a new PC545. At the same time, I was also doing other preventive maint stuff (stator pin connector replaced) on the bike and had guzzidiag running which is how I now know I have a problem because guzzidiag was indicating 14.1vdc@1100rpm then, I'm running off the batt at idle now.

I'll check the fuses for signs of heat/poor connections & batt connections. The relay terminals are all very clean & tight. I hope to get back out to the garage tomorrow to check the stator voltage.

Thanks again for your quick response & advice,

Art

-

1

1

-

-

Hi,

Can we discuss charging system issues again/still, I have a problem, my '03 V11 Lemans no longer charges at idle (was 14.1vdc @1100 rpm last spring). It appears the system voltage comes up at around 2400 rpm now versus 1100 before. The Odyssey PC545 is 2 years old and tests good, my headlight, tach & charge TT function normally. I spliced out the burned stator connector pins when I replaced the battery. I also attached a ground lead from the VR to the timing chest. The bike has a Kuryakyn led voltmeter that was connected to the headlight circuit by the previous owner, it always indicated an undercharge condition until I put the headlight on relays, after that the system voltage indicated by the Kury LED was reliable.

My plan is to now check the stator open circuit AC voltage & attempt to determine if the rectifier lost bias/open ( I'm a little unclear about checking VR though).

I was pricing VR's at Euro Motoelectrics and they have a disclamer..USE OF ODYSSEY BATTERY ( DRY CELL DESIGN) AND LITHIUM IRON BATTERY NOT RECOMMENDED OR SUPPORTED FOR WARRANTY. My bike has run a PC545 from '06 until 2020 when I replaced it with a new PC545. I sent them a request for more info about they're disclaimer because I want to continue using the Odyssey battery. Pricing on their VR's are more attractive than OEM.

I also wonder if I caused an issue by installing headlight relays. I'm unclear about the VR reference voltage than is picked up from the headlight circuit. By adding the HDL relays it removed the voltage drop in that circuit. Could it have effected VR sensing system voltage accurately?

Anyway, thanks for reading my thoughts here and please feel free to toss out opinions & advice, it'll be much appreciated.

Art

-

1

1

-

-

Hi Frey,

Hey, maybe someday we'll see you rumble into a MG rally on your new V11 Lemans like Terry used to......with Maggie on the back dressed in black leather head to toe. I don't think any of us would expect you to bring Maggie. Anyway, great to know who got the V11, good for you, enjoy it!

Art

-

1

1

-

1

1

-

-

3 hours ago, gstallons said:

How do these guys ever have time to work on bikes ?

Pics are probably taken afterhours.

-

1

1

-

-

FWIW, my '03 Lemans had an annoying hand numbing vibration between 3500-4500 rpm when I bought it in '15. The original owner installed DAS Mototec clip ons that I thought might be the problem but after reading posts that others had the same issue with oe bars, i let the clip ons stay. I installed a pair of "heavy" bar ends (don't recall the brand), gave the bike a "decent tune up" and somehow the vibration is no longer hand numbing.

-

1

1

-

1

1

-

-

On 12/11/2021 at 4:27 PM, Chuck said:

Art.. if it is leaning that much, just to be safe, check the bolt that attaches to the engine.

Hi Chuck,

My stand has a thru bolt into a tab welded on the frame but you're right, the bolt had backed out, when that happened the stand was almost useless. I refastened the stand and then went on to make a slight mod to the increase it's length by about a half inch and broaden it's footprint. The spring loaded up stand is still awkward to deploy because I have to lean the bike slightly right to fully extend the stand but had to do that before the mod, just not as much. I'm used to it, no big deal and I don't have to worry about the wind blowing it over now.

My stand has a thru bolt into a tab welded on the frame but you're right, the bolt had backed out, when that happened the stand was almost useless. I refastened the stand and then went on to make a slight mod to the increase it's length by about a half inch and broaden it's footprint. The spring loaded up stand is still awkward to deploy because I have to lean the bike slightly right to fully extend the stand but had to do that before the mod, just not as much. I'm used to it, no big deal and I don't have to worry about the wind blowing it over now.

....OK, in case I'm confusing anyone...the stand mod I did was on my '87 Lemans, not my V11 Lemans. Just thought I'd add that since it dawned on me that I'm on the V11 board and not the Tonti stuff group.

Also, I'll now check my V11 stand mount hardware too after some of you (Docc, Chris, etc.) enountered loose hdwe there.

Thanks,

Art

-

1

1

-

-

22 hours ago, Chris Wilson said:

Screen shot your image and then crop it tight with any free image software?

I use freeware Photo Editor to reduce the quality and then crop.

Chris.

[docc edit to show the reply outside of the quote window.]

Thanks Chris, I'll look into it!

-

1

1

-

-

Hi,

- I did the seat/high cam spring swap a few years ago. I think I checked cable slack to make sure I got full high cam but will recheck.

- I don't recall whether I move to high cam before or after ign "on".....in the Spring I'll try to figure out if either makes a difference for my bike.

Thanks!

Art

-

1

1

-

-

Hi Chris,

I did something like that to my Wing & LMIV. After installing new fork springs on the Goldwing, I felt the lean angle on the side stand (especially when the rear shock was aired up} was not only too severe but required more grunt to get it upright. So, I added a small shim to the bottom of the stand that also increased the footprint for more load bearing. On my Lemans, I added about 1/2" thick shim and doubled the size of the footprint. The side stand down lean angle was so great that it would be able to fall over if anything was in the the side bag. I'd post pics but haven't figured out how to make my photos under 200kb....something else I have add to my "things to learn" list!

Art

-

1

1

-

-

Geez, thanks for the quick replies! I guess I'm good to go then, what you're all describing is exactly what is happening. Terrific, I can cross that off my "things to do" list. And to the best of my knowledge and the original owner/po, the bike has the factory map and I'm really not enthusiastic about changing it because it runs great imo.

Thanks again,

Art

-

2

2

-

-

Hi All,

My '03 V11 Lemans, when cold, requires a twist of the throttle to start. The bike has always required a slight throttle manipulation for the engine to start & run when cold according to the previous owner. I figure the bike is fuel injected (15M PF3C)and shouldn't need anything other than run the "choke/enrichener/throttle plates" to high cam and hit the start button. When I do the high cam and hit the starter button, the engine cranks and wants to start...sometimes it will start momentarily then stall, other times it will crank and not start. However, it will always start & run with a little twist of the throttle. In early 2020, I had some time on my hands and did the "decent tune-up". IMO, since the tune-up, the difference in overall performance was a huge improvement. However, the twist of the throttle thing when cold still exists and was wondering if this is "normal". The owners manual says nothing about throttle manipulation during the starting mode.

I have looked/checked for vaccuum leaks but have found none other than the TB vac ports which I capped off. The tb shafts have very slight wear/side play but they dont appear to be leaking...the bike only has about 10k miles on it. The TPS seemed to have a smooth transition though the mv range when I set it...no hiccups. The mechanical high cam linkage & tb linkage are in good working condtion..no slop. The crank position sensor was out for a new oring, found no metal debris on the sensor. Plug wires & caps were replaced because one cap had tip over damage & high resistance. Air filter was replaced. Engine & air temp sensors seem to be working and display ambient temps until engine heat causes a rise.

Thanks for reading.

Art

-

2

2

-

-

Hi,

Andy, PL & LP...thanks for your thoughts and experiences, it's appreciated!

Art

-

1

1

-

-

Hi,

PhillipLarsen & BillyB - Thanks for the feedback and advice.

Andy York – The pinion seal didn’t appear to have had a leak but while the ring gear is out of the unit I’d like to replace the pinion seals too. And, I did feel a slight amount of pinion play like something going on in the lower pinion bearing area. However, it is an extremely low mileage unit. I did read somewhere that some of the pinions were not fully seated into the drive housing when originally assembled, the result was some endplay or slop but not enough to cause catastrophic failure.

MartyNZ – Thanks for the info & pics…big help! I totally forgot about heat. The thing was in the oven so I could get the bearing race to drop out in order to replace the outside seal….I should have tried hammering away at the ringnut at the same time…duh.

Thanks,

Art

-

Hi Phil,

I originally started down that road but after chewing up a couple brass drifts I switched to a steel one that began to destroy the nut. So, I figure before I get to the point of no return, I'd make or get a spanner socket. The drive is original to the bike and was replaced by the PO about 15 years ago because it leaked. I'd like to get this unit back into the bike because it is low mileage (under 6k), nothing needs to be shimmed and the paint finish matches the engine & trans. Yeah, I don't get why the ringnut is so tight other than maybe corrosion, the drive looks to have been well cared for during it's out of service years. Oh well.

Thanks,

Art

-

Also, I haven't figured out how to post pics here.

-

Terry Barnes is listed as a contact for the SOUTHWEST OHIO MOTO GUZZI BREAKFAST so, I assume he is still with us but I know for sure Terry Whittaker is not. That's all I know and I've never met Terry Barnes.

-

1

1

-

-

Hi,

While we're on the rear drive....is there anyone manufacturing or have available a spanner socket for the ringnut (#18) that retains the pinion assembly? I'm at a point where I've got a ringnut on order for the purpose of making my own spanner. I'd prefer to buy one already made since my machine shop consists of a cut-off wheel & Dremel tool.

Art

-

1

1

-

-

I thought the same...could be Terry Whitakers bike. He had a V11 Lemans & Centauro, lived in SW Ohio, passed a year or so ago. I think $3300 is on the low side for that bike if it isn't too fubar. Who knows if bags mounts are still available for those things and this one has them.

FWIW.......

SOUTHWEST OHIO MOTO GUZZI BREAKFAST UPDATE We have changed our breakfast meeting place and time. We will continue to meet on the 1st Saturday of the month, at 10:00 A.M. The new venue is: The Village Family Restaurant, 144 S. Main Street, Waynesville, Ohio. Terry Barnes will serve as contact person: Tom Rogers, 937-266-3971 or Terry Barnes, 937-287- 2851, oldmojo@yahoo.com. This may change down the road, or be supplemented should others want to pitch in.

Anyway, Happy Holidays y'all!

Art

-

1

1

-

1

1

-

-

I did what PO18guy did and then went to the local mom & pop cycle speed shop for the terminal ends. I believe I reused the wire boot up at the coil. The reason I replaced them was that the right plug cap was damaged in a fall by the PO and the fact that they were 18+ years old.

....I believe mine have the 5k resistor caps.

-

1

1

-

-

Scud, Thanks for the copper ground rod suggestion! I ordered a Mojo Lever and will go at the NM again. I see where you had posted at WGC back in August and I had commented there too but totally forgot about the thread there. Oops, old age hurts.

Bill, Goodluck to ya!

-

Hi Scud,

Thanks for the quick response and advice. I guess I'll get an order going for the Mojo Lever & Ru-glyde. I'm familiar with the Ru-glyde from when I had access to a Coats pneumatic changer.

On another related note, my No-mar came with a wrinkle paint finish and on the drop down center post. Some of the paint finish flakes off onto the wheel hub every time I lock down the post, I'm thinking about removing all the paint from the post....what were they thinking??!!

Anyway, thanks again,

Art

Charging Light

in Technical Topics

Posted

Yeah, I could have saved myself $300 by seeing how much more I could trim out, hardwire & replace this area but then it would be an issue in the future for me or the next caretaker to check stator voltage, etc.

I guess in this circumstance I didn't feel trying to salvage these 20 year old items would be an improvement.

Art