Doansci

Members-

Posts

17 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Doansci

-

This might help someone. (and apologies if it has already been noted) I had carefully set the TPS by the book and the bike (2002 LeMans) suffered from surging when hot and abrupt on/off throttle transition and slight pinking at full throttle. The surging and throttle transition made the bike frustrating to ride. I retested the TPS it was still 160mV with throttle plate closed = not significantly different than where I'd set it last year. I then noticed that when the throttle was pulled open that the first motion was to take up throttle shaft wear. (to check for wear, grab the throttle shaft nut under the throttle body and move it side to side. The right side has more play that the left, perhaps because of the return spring. There are rubber seals on the shafts but may be unable to compensate for the wear or have failed after 23 years.) In one of the TPS discussions KiwiRoy suggested that because the voltage increase with rotation is not linear that the goal of setting the TPS was not so much to achieve precisely 150mV (or 157mV), but to make sure the setting was on the tail of voltage increase. I pictured the voltage increase as a curve similar to exponential growth with 150mV somewhere close to the baseline suggesting that at 150mV the computer can sense the TPS but is not yet altering fuel settings. After setting the TPS the manual states that throttle plate angle should be set to 3-3.5 degrees. I wondered how to do this because I don't have Guzzidiag computer setup, but another post (I forget who posted) stated that throttle plate angle at idle corresponded to 470-480mV. Another post stated that instructions for installing a new mixture map that the idle throttle stop should be set at exactly 475mV. My idle stop was at 311mV so I decided to experiment with changing it. I set the TPS to show about 470mV just as the throttle starts to lift off the idle stop. As the throttle linkage is pulled the first movement takes up play in the worn throttle shaft and the mV increases. All the play is taken up and the throttle starts to open at about 470mV but my TPS reads about 420mV when the spring holds the throttle against the idle stop. (differing amounts of wear should result in different idle stop mV) With the throttle plate fully closed (as in setting by the book) the TPS shows about 220mV. I then balanced throttle bodies side to side. The result is dramatic! There is no hint of surging even at low rpm and low speed and the harsh on/off throttle transition is mostly gone. There is no pinking. It has really improved the bike. Yes, I know there someone has posted a tutorial for replacing throttle shaft bushings. I have even bought new bushings and seals and will get to it eventually, but I am very happy with the way the bike runs now.

-

LaGrasta - this makes sense, but I wasn't able to find the instructions at electrosport. Do you run it through a fuse or circuit breaker like Docc suggests? Tomchi, AudioMick and Docc - I do recall that the ground was to attach to the engine. Perhaps my memory confused this with a power wire like LaGrasta describes? I will reroute it when I install the new regulator. Docc - I tried to find Caig Deoxit a couple years ago and looks like it is mail order only for me. The connectors are bright and shiny. Speedfrog - the replacement regulator is arriving today so maybe mosfet next time. The description of the electrosport regulator also looked good. To everyone - I really appreciate your quick and detailed help. Your knowledge and willingness to help are impressive. Thank you.

-

Thank you Doc - it's just been ordered!

-

Thank you. Previous posts on the charging system describe how the regulator senses battery voltage from the headlight circuit and that resistance can cause over charging. My thinking was that there might be a poor connection there causing intermittent or slow response by the regulator that might be solved by running a wire from the positive battery terminal to the regulator. Is this a valid test or crazy talk? Thank you again! Shawn

-

2002 Lemans with 28,000 miles and most of its time spent on the dry side of the Cascades. Ducati Energia regulator. The charge light only illuminates occasionally. I have just replaced the old Odyssey battery with a new one. Battery voltage is 13+ volts after charge, but drops to 12.5 or 12.6 with the key on. It was also compared to the old battery by the battery shop and meets spec - 450 cca. The problem is the regulator works but it seems slow. Battery voltage will drop when the engine starts and runs - 12.5V or a little less. If given 2500 rpm the voltage will then jump up to somewhere in the 14 volt range and decrease to roughly 13V as it idles down but if run up to 3500rpm the battery voltage will run up to over 16V. For a while. Eventually the regulator seems to find the voltage and regulate it down into the 14V range. So - it seems to work, but slowly or intermittently. The regulator is mounted above the horns under the gas tank. (most pictures show it mounted between the horns, but this is not) I have checked and cleaned the bullet connectors from the regulator to the harness (all seemed good and free of corrosion). I've run a 12 gauge ground wire from the regulator case to the negative battery terminal and cleaned and tightened the ground strap from the negative battery to the back of the transmission. The underside of the regulator has greenish potting that has turned brown where the wires enter the case. I have been reading on the forum that the regulator "senses" the voltage and responds and this one does seem to do that - both initiating charge and, eventually, reducing the charge to less than 15 Volts. So, is the regulator working and the wiring harness a mess or is the regulator toast? BTW none of the relay or fuse contacts under the seat are melted - they all look like you'd expect. Hope to take this bike on a camping trip next week so appreciate your help and ideas. Thanks! Shawn

-

Thank you Docc and Phil! Excellent write-up Phil. No Guzzidiag (yet), need to fix the wear first.

-

Re-adjusting the TPS solved the problem. Unfortunately my initial electrical connections were not good enough to determine its pre-existing setting. Establishing good connections showed that there is significant throttle shaft wear causing about 40mV variability in the TPS setting. Throttle shaft wear can be felt by letting the return spring hold the throttle shaft closed and wobbling the lower nut on the throttle shaft. Both shafts are worn (24,500 miles) but the right side is worse maybe because the idle stop screw is on the right side. I set the TPS so 150mV was the absolute minimum reading when pushing on the throttle shaft nut. This usually resulted in 160-165mV when the throttle was closed by releasing the twist grip. Snapping the throttle shut or holding it closed with fingers resulted in greater variability in the reading but never less than 150mV. BTW all TPS voltages were measured with the headlight turned off (disconnected) to minimize battery voltage drain. Resetting the TPS eliminated the surging and pinging but it was not as smooth so I rebalanced throttles at 3000rpm and re-adjusted air bypass screws for idle. The right side air bypass screw is turned in more than the left probably due to the throttle shaft being worn more on the right. We then went on a 1000 mile ride in temps up to 100F and 0-5600' elevation and the bike ran very well - smooth without surging or pinging. 40-42 mpg. The only complaint is the throttle transition from off to on or on to off is too abrupt, probably due to throttle shaft wear. Are any throttle shaft repair kits available for these throttle bodies? Thanks for your help.

-

Phasen sensor is timing sensor on front of engine over cam gear? What was your source?

-

Was thinking that if TPS was correct, but the map was in the wrong places it might point to which sensors to check.

-

New manifold rubber sleeves last year. Fuel filter was replaced about 8,000 miles. Now has 25,000 miles.

-

Thank you all. Yes, 92 non-ethanol fuel is the best we can do here. Late last summer I did the decent tune-up starting with valve adjust etc. It made a remarkable difference with the surging and stumbling off idle but didn't eliminate it completely. Biggest difference was cleaning the bypass screws, resetting the TPS, balancing the throttle bodies and lowering the idle. It's only been about 1,000 miles since the tune and the symptoms have gotten worse as the temperature has increased so thinking there is more to do.

-

Hello, 2002 LeMans with 15M computer. A hot engine surges at small throttle openings just off idle up to at least 4,000 rpm. Also when hot the engine will ping accelerating hard from 4500 rpm to 5500 or higher in 4th gear. I'm trying to understand how these symptoms are related but need someone to double check my thinking. The 15M computer has a preloaded fuel mixture and spark advance map so fuel delivery and timing are not adjustable independently - correct? The start or "bottom" of the fuel map is closed throttle and as the throttle opens the computer increases the fuel proportional to throttle opening - correct. While the start or "bottom" of the ignition advance curve is 0 rpm and probably reaches maximum advance by about 2,500 rpm - correct? (was not able to find a timing curve on the forum) If the above are correct, then setting the TPS too far one way would move the starting point further up the fuel map so that the computer would provide more fuel than a correct TPS setting (computer thinks the throttle is open further than it is) while setting the TPS too far the other way would provide less fuel than a correct TPS setting (computer thinks the throttle is open less than it is). Because timing is predetermined by the ignition map, pinging under hard acceleration indicates the mixture is too lean at large throttle openings - correct? So surging at low throttle openings would likewise be due to lean mixture. Does this logic make sense? (provided all the sensors and computer are working correctly) Thank you!

-

Thanks for the new ideas. Would still like to find the swan neck Verlicchi style just for the clean V7 Sport style.

-

Looked at swapping the stock clip-ons so the bars would be on the back side of the fork tubes but risers are required for the master cylinders to clear the fork tops.

-

Wow, thank you all for the replies and ideas! FreyZI, it looks like reversing the LeMans bar clamps will leave out a screw anchoring the clamp to the top triple clamp. Maybe not a big deal but didn't try it - I should! Also, are those the stock riser clamps on your Tenni? AudioMick - thanks for your translation. Das Moto might become the best option.

-

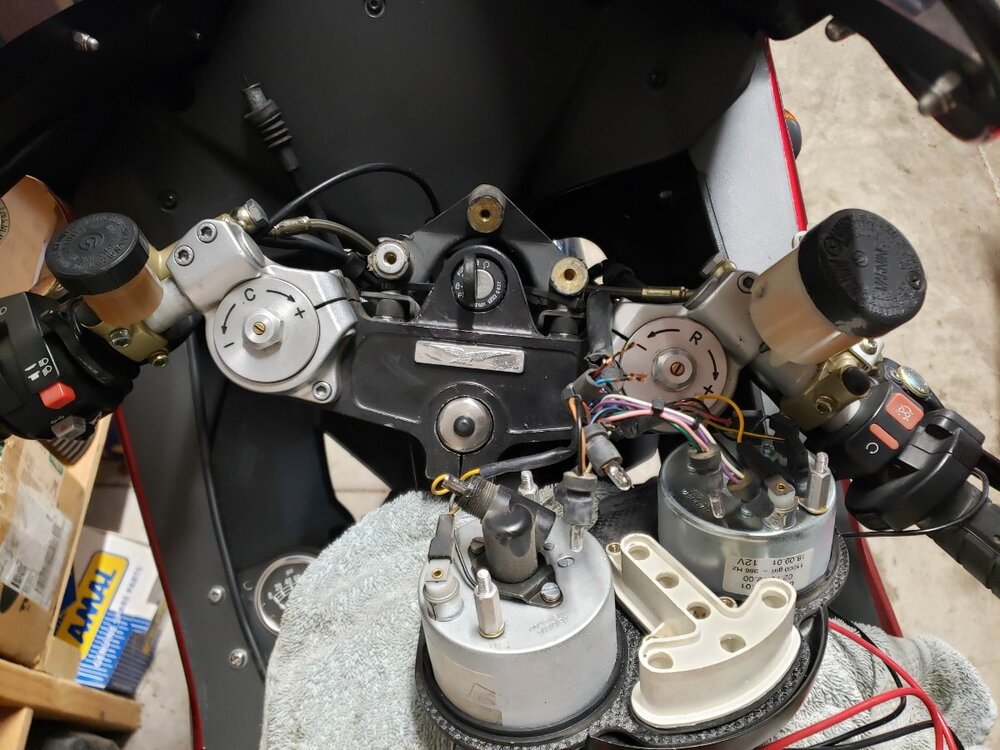

Here you go. The first picture shows stock fork-top clip-ons (dash in pieces looking for a bad charge bulb - it was OK). Second shows what I'd like to find. Thanks!

-

Hello, Thank you for letting me join. Bought a 2002 V11 LeMans last summer and this group has been super helpful and highly recommended by the folks over at WildGuzzi. So here I am. Hoping to use this a more of a touring bike so would like to raise the bars using some Verlicchi style swan-neck risers. A friend has them on his bike and they work great for keeping the weight off my overworked wrists. I've looked for Verlicchi bars on MG-Cycle and other places but can't find the large size clamp for the V11 - id needs to be 53 or 54mm. Anyone have a set to sell or trade? Thank you, Shawn