-

Posts

4,593 -

Joined

-

Last visited

-

Days Won

238

Content Type

Profiles

Forums

Events

Gallery

Community Map

Posts posted by Lucky Phil

-

-

1 hour ago, Kevin_T said:

Awesome work Phil!

I can't tell from the pictures did you hollow out the bolts or is that just spot facing for live dead center? Anyhow you're not going to pick up one of those puppies at fastnal. Looking at the picture of the bikes rear end what gauge wire did you use for safety wire? Also the breather do have a post for what you did for the breather is there a reason as to why you made a stack with a nut in between the breather and the drive?

No the end is just drilled for the live centre. Too much stick out for a 10mm shaft for threading Titanium. You need the support. Safety wire is .028" my preference for most fasteners. Anything thinner is too thin and .032" is a pain to use. I have some thinner wire maybe .022" or something for light fasteners but I don't have much use for it on things these days. The breather is standard as far as I'm aware.

Phil

-

1

1

-

-

56 minutes ago, activpop said:

Thanks Phil, I'll try that. I never had a clue that two fork legs could act so differently. I would think from a physical standpoint the unequal actions would have different forces exerted on each side of the axle. I guess the axle is pinned in so tightly that nothing negative gets transferred to the wheel, but I'm no engineer. I'm anxious to see what the shop says.

It's very common to have the rebound and comp in separate legs. USD forks and axles are very ridged these days so it's no issue.

-

1

1

-

-

8 hours ago, activpop said:

I never noticed because I think I only pumped one. It was mentioned on another site that they are supposed to be like that. One is for compression and the other is for rebound. I never imagined each leg could act so differently. I'm no suspension expert, but I can call one come Monday to get their take. There is a shop in California that deals with nothing else.

First time ever replacing seals. It was easier than I thought.

You should still be able to feel the damping working in the compression leg if they are indeed comp one side rebound the other especially if you remove the spring and pump the cart itself.

Phil

-

1

1

-

-

What was it like before you replaced the seals? Did you notice. The cart may have failed internally before you pulled it apart and you hadn't noticed. Failing that remove the cap and spring and manually pump the cartridge.

Phil

-

1 hour ago, Guzzi-in-Vancouver said:

@Lucky Phil thank you for asking, I hadn't realized it had been left unsaid, and sorry for the late reply.

Yes, the left-hand side throttle body (or is it boot?) had come off, and that was the primary issue. In trying to re-seat it I ended up messing up the screws with the yellow paint, and then the throttle bodies also had to be re-synced. Then all sorts of other issues came to light.

For fun, I made a little collage if anyone wants to have a go at diagnosing what was discovered!

Ok thanks for letting us know. Looks like a few things to replace to bring it up to scratch. What part of the casing is cracked?

Phil

-

Machined up the other special bolt for the rear drive.

-

3

3

-

-

Second bolt made and fitted.

-

4

4

-

-

14 hours ago, gstallons said:

Dissimilar metals are the least likely to gall. Think steel shaft/bronze bushing.. Similar metals such as aluminum cannot be threaded together dry . I KNOW .

I've used a lot of aluminium fasteners in aluminium cases without anti-seize and never had an issue. It's what I used before Titanium became affordable. They were anodised 7000 series though.

A steel shaft in a bronze bushing is a bearing situation not a galling situation we are talking about here. In Ducati oil pumps the driven steel gear rotates on a ground steel post without any galling.

Phil

-

1

1

-

-

2 hours ago, docc said:

And I thought a thread sealant/anti-seize or even a lubricant is indicated with any dis-similar metals threaded together?

The thing people forget with dissimilar metal use is there needs to be some form of electrolyte between the 2 for any issue to arise. Putting dissimilar materials together in a benign environment isn't an issue but in a salt air or salt water laden environment then you can have problems.

Phil

-

1

1

-

1

1

-

-

11 hours ago, Meinolf said:

Hi,

excellent discussion on the topic. Can anyone confirm if 105/G08E is the correct Andreani article number for the 40mm black Marzocchi forks on a 2001 V11?

Thanks

MeinolfBlack 40mm Marzocchi forks without a separate axle nut ( the axle threads into the l/h fork leg) then yes they will fit. They will not fit the early silver 40mm forks because the fork bracket is different internally and the later black 43mm forks because the fork cap thread pitch and Diameter is different.

Phil

-

1

1

-

1

1

-

-

4 minutes ago, gstallons said:

Do ti fasteners require thread lube or anti-seize when you are assembling ?

Yes, copper anti seize.

Phil

-

3 hours ago, LaGrasta said:

Yes, skeptic here as well. After some research, you'll be disappointed to find many of the items we purchase, originate from China. In the case of the seals, there are some that are not, but many are the exact same ones as these. At any rate, mine have been good thus far. I did however keep the original dust seals. I like the spring it had on it.

Not disappointed at all I'm aware of this and buy a lot of stuff that's made in China, pretty hard not to these days. The thing to bare in mind though is that at least large "known" brands have the buying power and leverage with the manufacturer to ensure high quality and sometimes I suspect better materials. There is also the question of quality grading. I have bought identical machinery tooling and accessories like rotary tables etc from a particular retailer and the exact same part from the exact same factory from other independent sources a few times now and the part from the original large retailer is always slightly better quality, fit and finish. I suspect they have the buying power to make the manufacturer send them the first quality items only and the lesser outlets get the second grade stuff.

Phil

-

3

3

-

-

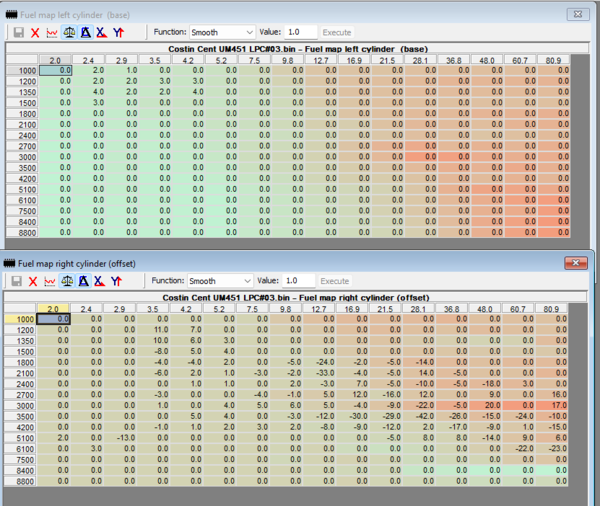

I decided to fine tune the fuel mapping on the Daytona engine. The bike ran very nicely but at town speeds the initial crack of the throttle needed some refinement. It didn't jerk around or anything like that but I could here from the exhaust it wasn't perfectly clean although as I said it didn't present any rideability issues. I'm being super fussy here but I also now have access to original .bin files for the Daytona and Centy engines and my original map was quite a bit different so I decided to make up 5 new maps and load them and evaluate by the old seat of the pants methodology. Once I got to the second of my new maps I stopped there because the bike was running as close to perfect as you could ever want. Anyway here are the Delta main and offset maps to show the differences between my original maps and the new map I came up with and decided to stick with.

-

2

2

-

1

1

-

-

In my continuing journey to improve my machining skills I decided to make replacement Titanium bolts and washers that mount the rear bevel box torque arm bracket to the bevel box. One bolt and two washers done one bolt to go. I've also got enough Ti stock to make a replacement bevel box torque arm bolt as well.

Phil

-

8

8

-

-

4 hours ago, LaGrasta said:

Marchozzi fork seals, $5.50

AliExpress

I currently am using these on my 2003.

I considered Aliexpress seals when I rebuilt my last 43mm forks but considering what a PITA fork seal replacement is and the small saving you make on the seals I went with a known brand.

Phil

-

1

1

-

-

The old help me fix this with "drip feed" information thread. Bean here many times. I guess we'll find out in 2 pages time it's got a 2 into one exhaust, pod air filters and high comp pistons.

Phil

-

1

1

-

-

1 minute ago, thumper said:

The sensor has been replaced that is why

So you don't mention that in the OP!

Phil

-

1

1

-

-

It's the sensor. Why would you chose the ECU ( the expensive bit) over the cheap less reliable component?

As the engine warms up the trim reduces to zero at 90 deg C and then goes negative the hotter it gets after that. I think if you disconnect the sensor the ecu goes to a default temp setting.

Phil

-

1

1

-

-

My new car doesn't even have a dipstick, stupidest thing ever. You take the car out and drive it for at least 30min then park the car on level ground and do an oil level check via the entertainment screen. It elevates the engine rpm to 1000 for about 30 seconds and does an oil level check and gives you the result. Like I said stupidest thing ever. Whats happened to German engineering? Millennials is what's happened.

Phil

-

3

3

-

1

1

-

-

5 hours ago, LowRyter said:

Nope. The F4 was perhaps even a better example. This is why since the '70's, design has focussed on reliability and maintainability.

Well the Germans were way in front of everyone. Part of the reason they used inverted V12 engines was ease of maintenance. On a ME109 for instance the crews could do most of the engine work from the ground without stands by simply opening the bottom engine cowls to access the engine top end where most of the maintenance items were. On a Merlin you were working from a stand 6 feet off the ground on top of the engine cowls.

Phil

-

4

4

-

-

17 minutes ago, Pressureangle said:

I met a Man at a UAW local meeting once, about 1985. He was an engineer for Cadillac; salary somewhere in the mid-80,000's as I recall. His job?

Find the shortest route for the fuel, cooling, and vacuum hoses. Co-ordinate that with the assembly line engineers to balance material costs with production costs.Yep I often see on car forums guys that remove stuff from cars because "they aren't needed". The fact is every car and bike is designed down to the last cent and unless there is a big customer appeal issue then it either doesn't get incorporated OR it's just enough to do the task. My FIL worked at the GM test ground here for over 40 years testing and developing new cars and prototypes and I meet owners all the time that modify production stuff that they spent many many hours developing and think some backyard business that's R$D consists of a few hundred miles driving on public roads has it all covered.

The Supra has a 5 pound weight bolted to the chassis cross member near the diff. It's called a chassis damper. Whats it do? not sure but I could have an educated guess. Clowns remove them because it's useless and saves weight! My advice is that unless you know precisely what it does and have the knowledge of a chassis engineer then better to leave it installed because the bean counters at BMW won't have it there unless it's necessary. A five dollar saving on a chassis damper not fitted translates to probably a million dollars on the bottom line to BMW/Toyota. They wouldn't fit it unless it was necessary.

Phil

-

3

3

-

-

55 minutes ago, docc said:

My understanding is this is exactly what the Phillip's head was designed for: for the driver to "cam out" on assembly without over-torquing.

They were never designed to take apart.

Agreed on Torx and Robinson drives being positive engagement, both in and out.

Yes docc but don't confuse it with the superior JIS ( Japanese industry standard) cross head screw which the Japanese developed and use which don't cam out.

Phil

-

7 minutes ago, docc said:

I have long been fond of saying that consumer products, perhaps all the way from toasters to airliners, are designed with two purposes: build and sell.

You need to pull down a modern car engine docc to properly understand how much of the design is about production line speed and ease of assembly and minimising machining. Terrible.

Phil

-

2

2

-

-

On 5/19/2024 at 1:36 PM, guzzler said:

Looks like she might be a bit rowdy with those pipes....?

I'm not a fan of these short mufflers and brand that's a box under the gearbox ( brand I forget, probably because the exhaust is so ugly to me) for aesthetic reasons. The rear wheel/swingarm area of a V11 Sport isn't the prettiest part of the bike esp with the enormous std rear hugger and the flange around the bevel box. Quite ugly and heavy looking in my eyes. A nice muffler style contributes in a large part to breaking up this visual and minimising the appearance and impact of this rear end appearance. Short or non existent muffler styles that expose this area do the opposite and draw your eye and therefore attention to the the heavy look of the rear end. I much prefer the std bike without the factory rear hugger for this reason as well even with std mufflers. One of the highlights of going to custom wheels was being able to machine off the bevel box shroud for a cleaner lighter rear end appearance.

Phil

Changed fork seals and I have a problem

in Newer models

Posted

My feelings aren't hurt, really

Phil