JBBenson

-

Posts

493 -

Joined

-

Last visited

-

Days Won

15

Content Type

Profiles

Forums

Events

Gallery

Community Map

Posts posted by JBBenson

-

-

I had Todd Eagan rebuild my forks including new valves and springs, best upgrade I ever did for my bike.

Money well spent. Do it.

-

What diameter forks does it have?

-

Wow, that's a sooty air-bleed screw. Better clean the throttle bodies when you have a chance....

The breakout harness is a great mod, makes it super easy to check the TPS on a regular basis.

Now that's it's running right, next up is a good old "Italian Tune Up". Add some fuel system cleaner of your choice, warm it up and screw it on..!!!

Czakky's right: when they are sorted, they are great!

-

Thinking about getting a big twin, probably the Cali 1400, for long distance touring.

I was looking at the new Harley Heritage softail, but who am I kidding? Not a Harley guy. Besides, I can pick up a new or nearly-new Cali 1400 for like 10k less than a base level Harley Davidson.

Any thoughts from members who own or have owned both the V11 and a 1400?

-

Once you set the TPS, try the “White Knob Method” to balance throttles....copied from an older tuning thread. This method is a quick way to get your bike running well without going too deep into the brambles:

1.

Back off the RH throttle stop. Unless you have some super high mileage bike where everything is worn out and sloppy, using both will make you crazy.

2.

Open bleeds one turn each. ("Micha's method") 1 turn is almost always right. Make sure the screws and ports are nice and clean.

3.

Sync using white knob at idle. Like I said, some frown at this. Guess what? If they are synced at idle, it will be synced off idle.

When the throttles are open (>3k) the white knob needs to be moved a lot to make any difference in vacuum. This is because the small adjustments the white knob makes gets lost in the large flow of air coming through, and tiny imbalances in throttle vanes will be hard to see on any kind of meter, even the expensive one I bought.

You can turn the white knob and the throttles will appear to be in balance at higher RPM's. But they're not, which you will see when it drops to idle. Then you can use the bleeds to try to even it out, which is what I did, and then it idles worse than ever.

In short, the ultra tiny differences in throttle openings will be revealed at idle but will be lost at higher RPM's. If the idle is balanced, then higher RPM's will be balanced too.

Try "JB's" method, and sync the throttles at idle using the white knob. Turn 1/8 and blip throttle and let it settle. Keep doing this until it smooths out and is in balance. The idle will probably creep up as it smooths out (you can adjust this later using the LH throttle stop screw). It will never be perfect but you can get it close. Check "off idle" RPM's as you get it smoother, I bet they will be in sync too.

Yes, this method is backwards, but since your bike runs like crap right now, why not try it? I went through ever "method" before doing it this way, and now my bike runs like a sewing machine and pulls like a locomotive...

-

Start here with basic tune up:

-

1

1

-

-

PM sent

-

On 4/7/2019 at 11:12 AM, docc said:

I've only dropped my sump twice in over twenty oil changes. Good advice on the threads and alignment. Years ago, Ryland3210 did extensive evaluation of the filter gaskets and declared that the filter needs to be tightened 1 1/8 (one and one eight-th) turns after the oiled gasket makes contact. The UFI gaskets were crap and likely contributed to the early filter failures.

Do you change the filter through the manhole? If so, how do you get to the hose clamp which I am sure you are using...?

Asking for a friend.

-

1

1

-

-

That may have been drilled out for some reason. Looks like a trip to a good hardware store is in order, you’ll need some grommets, a couple of spacers/bushings (the “collars” mentioned above) and some nice stainless button head hex head bolts for a clean install.

That being said, the grommets may be a problem to find ones that fit well, so a work around is using a combination of stainless washers and rubber washers to isolate the cowl from the hardware to prevent stress cracks.

-

I don't think all V11 forks are the same diameter. My Sport has 54mm forks. I have a set of OEM clip ons if you need them, PM me.

-

PM sent.

-

Smallest church in America.

-

3

3

-

-

I have tried a few, this was the best one:

Cortech Super 2.0 Low Profile Tank Bag, see it here:

https://www.v11lemans.com/forums/index.php?showtopic=19319&page=64

-

1

1

-

-

Gee I could get the Ohlins and the fairing for 1700.

Scud what’s the diameter of the Ohlins forks?

Hmm

-

Zion Cemetery. Hilton Head Island. Italian Stallion. Southern Gothic.

That's 9 words.

-

3

3

-

-

V11 converted to carbs. Never seen this done before, but either the owner is genius or he’s a nutcase:

https://mohave.craigslist.org/mcy/d/2003-moto-guzzi-v11-sport-org/6722902061.html

-

Is that the ignition-on start-up cycle we are seeing?

-

1

1

-

-

Actually, the stator and regulator both need upgrading on the V11, they were always sort of weak. There are kits that do both.

-

I am interested in this thread, I feel my OEM regulator is the next thing to go.

I have my eye on the offerings from Guzzitech.

Todd offers two RR's for the V11, one for $110.00, and one for $120.00.

-

Yes, I have checked that vent, it's clear. I have also removed a bit of RLSP "Heavy" from the transmission. I will check the vent on the final drive too.

So, the conventional wisdom is now the Blue Yoghurt? OK, I'll put that in next time.

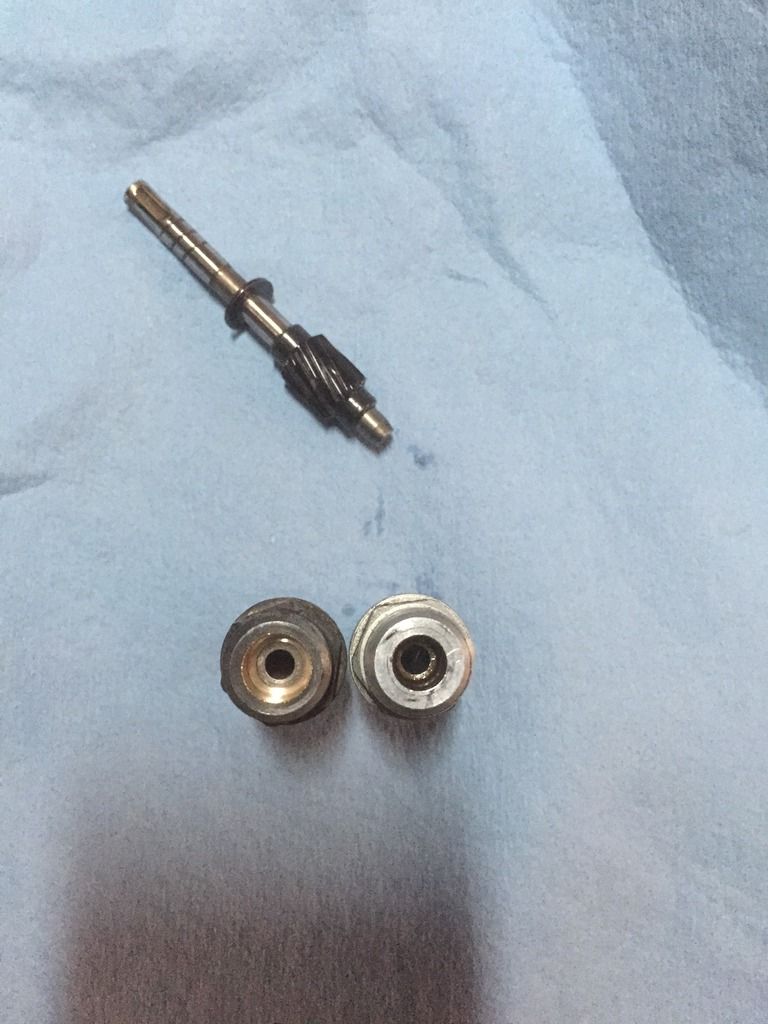

I am pretty sure the spiral grooves on the spindle are designed to lift lubricant up into the housing. That's what they look like to me. Like a "spiral groove bearing". I might be wrong. But yes, it probably shouldn't get up into the cable housing. Not sure why it got up that high. The oil has been steady in the middle of the sight glass. I don't think its overfilled.

-

Docc, how did you get the circled assembly out? That cap area was leaking on mine, thats why I replaced the entire angle drive (initiating this entire fiasco), I figured it was a sealed thing.....no?

-

So, it is the "connector shaft"/ "stud" that failed. It is a separate piece supplied with the replacement angle drive?

Simple enough to use the factory connector shaft/stud with the MGCycle replacement angle drive.

Yes, the "connector shaft" slides into the angle housing as a separate piece. Like I said, the new "connector shaft" seemed to have a gritty fit, it didn't feel quite right. The older shaft slipped right in "home" and turned smoothly. So, maybe the issue is the fit of the new parts to each other, or poor quality metal for the new, non OEM shaft. Maybe a bit of slop in this application is preferable to a super tight fit....?

In any case, I recommend using the OEM "connector shaft" with any new angle drive from MG Cycle. Take your time to make sure they are all "home" in their respective sockets, the "connector shaft" (male) into the female spindle drive receiver, and the bottom of the speedo cable (male) and the female receiver at the top of the angle drive.

-

1

1

-

-

Here's what I found. I used the old angle-drive stud (from the housing that was leaking) and put it into the new angle drive and reassembled. I spun the back wheel and it looks all buttoned up. The angle seems to turn smoothly with the older stud in place. Not frozen.

Thinking about it, when I inserted the then-new stud (which broke later), it didn't seem to fit very well into the angle housing. I don't know why it snapped off, but if it happens again then the new angle drive is to blame, not the new, ill-fitting stud.

I'll have my Speedhuts by then, hehe....

-

1

1

-

-

Okay, I see the thrust washer is under the screw-in housing and on top of the drive gear on the drive spindle/pinion:

OK, then the washer is on top of the geared spindle? Then how can it fall off? According to guzzimeister, you need a dap of grease to "pick up" the washer using the spindle drive....?

I want to remove the housing and get the broken stud out of the little "cage" on top of the spindle drive.

BTW, for those that installed Speedhut gauges, how did you cap off the transmission drive hole when you removed the speedo angle drive? Do you know the thread size and pitch? I was thinking of getting a nice cap or something.

Balance synching after loading Meinolf's bin

in Technical Topics

Posted

Clean the throttle bodies (especially upstream) thoroughly, as well as cleaning the butterfly pivots, inside and out.

I had the same problem you did, and it was a build up of gunk (probably from Ethanol in the fuel) that was not allowing the butterflies to completely close, or to close erratically.