-

Posts

936 -

Joined

-

Last visited

-

Days Won

42

Content Type

Profiles

Forums

Events

Gallery

Community Map

Posts posted by MartyNZ

-

-

On 12/25/2021 at 1:04 PM, Tomchri said:

What dependable car ? Yes a w123 , boring but dependable, same era for the K 1000. 1100 late 80 early 90s. Great French engineering those engines. My friend passed 476k km this summer, same speedo,,,, hello. D IPA time

Cheers Tom.

.

I had to look up what a W123 was, and yes, now you mention it, there's a lot of them on the road in NZ. MB seems okay, but many recent models of European cars don't seem to age well. Great when new... The Volvo is an obvious exception. Great cars, similar reliability and durability to Japanese and Korean cars.

-

2

2

-

-

There's some discussion here that might help you.

https://www.guzzitech.com/forums/threads/bike-wont-start-dsb07-dsb08.2717/

-

1

1

-

-

Art, my bike needed a twist to start, just as you described. It came alive with a Ba-boom to wake the neighbors. I always felt bad about getting rpm above idle with low oil pressure. Then I loaded Meinolf's BIN file to the ECU. After that it starts and idles without touching the throttle.

-

1

1

-

-

On 12/4/2021 at 2:39 PM, Tomchri said:

And a 59 Pan head in Sahara...

As Tom suggests, a bike without a temp indicator is normal. You know what your oil temp is and it bothers you. Maybe you actually don't have a problem.

Engine oil needs to get up to 100°C before water condensation evaporates.

Cheap oils can tolerate 150°C without degradation, and Group 3 & 4 PAO/Ester oils handle over 200°C. Some engine oil additives don't work until the engine is up to temp.

Hot is good

-

2

2

-

1

1

-

-

11 hours ago, guzziart said:

Hi,

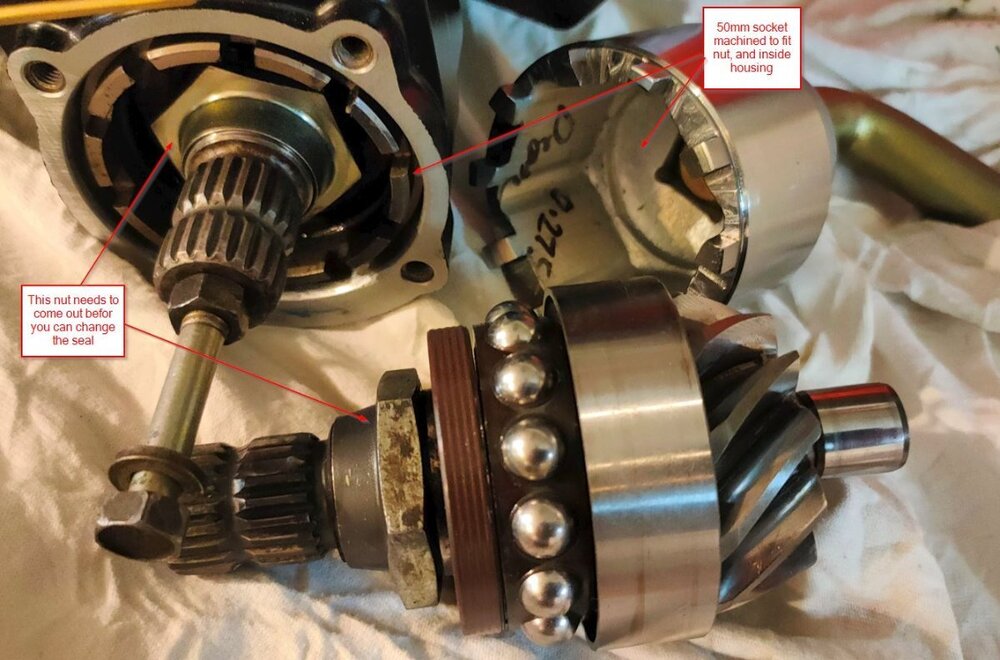

While we're on the rear drive....is there anyone manufacturing or have available a spanner socket for the ringnut (#18) that retains the pinion assembly? I'm at a point where I've got a ringnut on order for the purpose of making my own spanner. I'd prefer to buy one already made since my machine shop consists of a cut-off wheel & Dremel tool.

Art

I made a ring-nut socket from a 50mm hex socket.

But first, channeling my Father "if it isn't broken, don't fix it". I think you should only remove the pinion if you must change a leaky seal on the pinion shaft.

Anyway, you would need to remove the #13 nut, as the seal is behind it.

I used a hot air gun and heated the housing around the pinion bearing to 100°C. Nut #18 undoes easily then, and a gentle biff with a slide hammer and the pinion assembly will pull out. 100°C is safe for the seals and O-rings, but don't get much above 120ish°C. If you don't have a IR heat sensor, then a temp where you can touch the housing but can't hold your hand on it for a second is about right.

Nut #13 is staked into a slot, and is tight. I drilled and split the old nut, but then of course I needed a new nut... and a shaped wood set of vice jaws to grip the pinion gear to tighten it back up. Lots of swarf spiraled off the outer end of the nut as I tightened it, so good cleaning is needed.

-

1

1

-

-

On 12/1/2021 at 5:10 AM, docc said:

Most likely the big seal, #27. Simple enough to replace the O-ring, #24, as well. The large seal is not hard to change.

If the leak appears on the right side of the rear drive, the small seal, #10, needs changing. The crown wheel bearing,#12, must be removed and replaced for this.

Docc's second suggestion is the worst news, but is actually more likely. if the RH end of the crown wheel has rust pits on it, then the #10 seal needs to be replaced, after you blend out the rust (if minor) or fit a seal saver (if rust will chew out the new seal). Be aware of the seal orientation. It looks to be in backwards when correctly fitted.

A leaky #10 seal allows oil to travel along the axle cavity inside the crown wheel, and the leak shows coming out the LH side of the box.

-

1

1

-

-

1 hour ago, Gmc28 said:

any takers on the question about what a guy should do with that air temp sensor-in-the-bottle? re-attaching it to the box, or is there a good reason to leave it with the goofy water bottle setup, or somehow "upgrade" that?

You should put the sensor back on the airbox where it was designed to be.

-

2

2

-

-

The air intake temp sensor should be in a position to measure the air going into the air filter.

DD mounted a sensor I made for him above the rear shock. Pictures and ride report here:

https://www.v11lemans.com/forums/index.php?/topic/19831-air-temp-mod-for-no-air-box/

The extended sensor is just the equivalent thermistor wired to an extended loom, with the last 100mm or so stiffened with a 3mm steel welding rod, covered with heat shrink.

-

2

2

-

-

-

2 hours ago, docc said:

My Sport made it's first 40,000 miles/ 64,000 km on Castrol GTX 20W-50 (which is, of course, not "Castrol R). This was, for me, a holdover of a trusted motor oil from my American muscle car years.

I migrated away from it when a trusted engine mechanic share that he did not care for it as it turned all of the internal components to a bronze-colored brown hue.

Ha! I though all engines were that color on the inside!!

I stopped buying Castrol when they started advertising Syntec as "full synthetic" despite the fact that it was made from a Group III mineral base oil.

Because of Castrol, nowadays the advertising term "synthetic" applies to any mineral oil with extra processing and a higher price tag. All the manufacturers now sell a "synthetic" Group III mineral base oil.

True synthetic oils are Group IV base oils made of polyalphaolefins (PAO) or Group V base oils made from esters (or other synthetic chemicals). I use an Australian oil in my air-cooled bike that is a mix of Group IV & V. I try to avoid products from manufacturers who imply lies in their advertising.

-

1

1

-

-

14 hours ago, Lucky Phil said:

Don't forget that one of the best lubricating oils ever, even compared to modern oils was/is vegetable bases lubricants such as Castrol R. Very difficult to manage even for racing as it was corrosive and needed to be drained after every meeting plus other issues like gum formation but as an actual lubricant it was very good.

Ciao

A flatmate years ago always wanted to mow the lawn when we had two stroke mower fuel mixed with Castrol R. It had an awesome smell.

https://www.motorsportmagazine.com/archive/article/july-2000/55/castrol-r

The storybook hero WW1 flying ace "Biggles" had to wipe castor oil off his goggles when flying his Sopwith Camel.

-

2

2

-

1

1

-

-

1 hour ago, Kiwi_Roy said:

I did a really interesting experiment a while back with a mixture of Sulphuric acid and an organic known as Nitrobenzine. The two solutions were mixed in a beaker with lab stirring system so it was a homogeneous mix.

Ha, reminds me of an experiment I did as a school kid. I thought the nitrobenzene was related to tri-nitro-toluene (TNT), so I mixed up a batch of nitrobenzene in the chemistry lab, and poured it into the fuel tank of the big old Dennis school lawn mower. I watched the mowing for a long time before I realized I wasn't going to see anything exciting.

-

2

2

-

-

22 hours ago, Weegie said:

Hi @MartyNZ I'm struggling then, if the pump is reaching rated pressure on the engine, then what's the problem?

No problem Weegie, I was just surprised by how easy it was to pump oil through the oil pump.

-

1

1

-

-

36 minutes ago, billgreenman1 said:

Getting the throttle bodies loosened is the hardest part. I'm afraid of breaking the mounts. Hence I have new ones but have procrastinated this procedure.

Dunking them in boiling water, and using a smear of oil makes things easier.

I think there is an order of left or right first that works best too.

-

How about this thing to beat the paint off your top fork yoke? Join the clan!

-

1

1

-

1

1

-

-

On 11/10/2021 at 6:11 AM, Weegie said:

Real test is engine oil pressure, what is start up pressure on cold oil and what's the normal running pressure?

My Sport, the nearest I have to a V11, will hit 70psi or so on a cold engine running 15/50 grade oil at 20C ambient, I notice you're using a 5/50 Penrite it may be a little lower, but probably not as much as you'd imagine, if at all.

Normal running at 90-100C I get 60psi all day long.

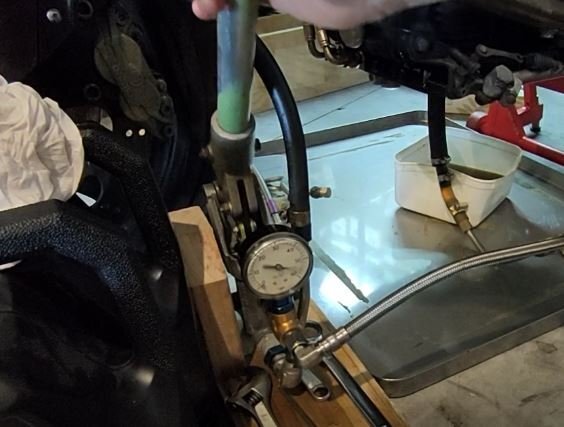

Using a hand pump, I could easily exceed the gauge range limit of 60psi, and, after 20 seconds got oil dribbling down from above. I don't have any concerns now about oil pressure.

On 11/10/2021 at 10:37 AM, Lucky Phil said:...was postulating ... on the reasoning behind using helical gears in the std pump as opposed to straight cut gears.

Thanks for the advice and comments. Helical gears explain why I could force oil past the main oil pump.

Now I should be able to use that little hand pump to test a pressure regulator.

-

1

1

-

-

20 hours ago, Kiwi_Roy said:

I don't know of any grease that actually conducts electricity, take your multimeter on Ohms and see, take a picture and post it here if you find a conductor.

I did find a conductive resin (I know, too much junk lying about) and it was very conductive. The uncured "part A" measured at 2Ω over 10mm in a smear left in the lid. Nice, but I can't think of a use for it in my bike.

It does tell me that a conductive paste is possible, but it would be bad in an ignition switch.

-

1

1

-

-

18 hours ago, Kiwi_Roy said:

I don't know of any grease that actually conducts electricity, take your multimeter on Ohms and see, take a picture and post it here if you find a conductor.

Good question. I looked at the "Carbon Conductive" grease mentioned by P6x Carbon Conductive Grease (mgchemicals.com).

This "conductive grease" claims resistivity of 114Ω.cm. Since resistivity is the inverse of conductivity, then this is actually about as conductive as drinking water. (IE very poor)

So anyway, I measured the resistance of silver goop and C5A copper anti-seize. The resistance of both was too high for my meter to measure.

-

3

3

-

2

2

-

-

On 11/19/2021 at 5:09 AM, p6x said:

I am thinking about either Dielectric grease, or in the case of the Switch, something like "Carbon Conductive" grease, such as the one proposed by MG Chemicals.

So that would be two different type of greases:

The Dielectric one, that needs to "isolate" the connection from moisture, not conductive;

The "Conductive" one, this one should be used as an ointment inside that infamous contact switch. While retaining the moisture repellent property of the other type, it does not impede proper contact between the terminals.

I could even pass on the Dielectric and only use the Carbon based one.

What do you think?

Imagine the bad things that will happen when "conducting" grease gets spread between contacts inside the switch. Most conductive greases are designed for static voltage control or slip rails. They are not for ignition switches.

Ordinary non-conductive (dielectric) grease is best. Vaseline is a good dielectric, but gets thicker in cold and could hold contacts apart. Lubriplate DS-ES grease is designed for switches, but any white lithium based grease will be good.

Most connectors benefit from liberal application of dielectric grease. I wrote about this here: https://www.v11lemans.com/forums/index.php?/topic/19693-aircraft-piloting-analogies/&do=findComment&comment=259237

-

1

1

-

2

2

-

-

15 hours ago, docc said:

Hmm, I was thinking it meant he removed the terminals in the relay bases and tightened ("Crimped") them . . .

You're probably right. That would be Kiwi_Roy's "Relay Base Repair" See attachment.

Cash1000 and I already did that repair some years ago. Maybe next time we should renew the terminals instead of just crimping.

-

2

2

-

1

1

-

-

9 hours ago, cash1000 said:

What's he mean by remove pins and crimp terminals ( see invoice)?

I think he removed some spade sockets, and crimped on new ones.

-

1

1

-

-

I couldn't read the marks on your picture, so I looked at the original pic. It says FRC7C-SR-1, 12VDC, NO 30A, NC 25A, at 14VDC

Spec sheet attached.

I do like the idea of the wider 4.8mm pins rather than the thin 2.8mm pins 85 & 86 on some Omron relay types.

-

1

1

-

1

1

-

-

After having the oil module and cooler off my bike, I thought I should prime the parts with fresh oil. I was surprised to find that oil pumped through the oil pump at quite low pressure. Does this mean the pump is worn? I thought a positive displacement gear pump wouldn't allow oil past unless it was turning.

Picture below shows filling and purging the empty oil cooler.

Picture below shows pumping oil into the oil pump intake. Oil flows with pressure above 68kPa (10psi) and eventually drips down from above.

-

3 hours ago, ScuRoo said:

So... I noticed on Pressureangle’s post his pic (which I’ve magnified) the top spur gear overlays another gear behind!

Huh?

My question is - so what is this doing?

Guess it’s driving something.

Can this be lightened also?

That's the phonic wheel. As the teeth go past the rpm and TDC sensor, the sensor gives this information to the ECU. Now you mention it, it could be lightened, but just not the diameter or tooth mass.

-

1

1

-

Nero Corsa Discovery and Refresh

in 24/7 V11

Posted

Possibly that weld can be as good as the original material, but not stronger. Because the weld attaches to original material, strength is limited by that. The weld looks good, but a strong weld depends on lots of things. Paint & oil contamination, incomplete weld penetration, porosity, and variations in any residual heat treatment all make restoration of strength difficult. But if it was me, and since the plate looks like the improved version, I'd leave it there. Watch for oil weeping through the weld after a long run.