-

Posts

935 -

Joined

-

Last visited

-

Days Won

42

MartyNZ last won the day on November 25 2023

MartyNZ had the most liked content!

Profile Information

-

Location

Christchurch NZ

-

My bike(s)

V11 Sport 2003

MartyNZ's Achievements

-

MartyNZ started following Throttle body and signal indicator

-

If you have intermittent operation of the indicators, then you have bad connections or bad grounds. If both sides flash at the same time after fitting LEDs, you need to modify your dash lamp circuit. See: https://www.v11lemans.com/forums/topic/30710-signal-indicators/?do=findComment&comment=291012

-

Have you looked at this? It might be a RH TB, as it has a TPS on it. But it seems to have the idle-up cable connection that is only on the LH side on my bike. No, I got that bit wrong. https://www.ebay.com/itm/166294418426?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=upabpsgjsow&sssrc=2047675&ssuid=e8jR-wz6R-m&widget_ver=artemis&media=COPY

-

MartyNZ started following 20240329_124536.jpg and 20240329_134755.jpg

-

-

MartyNZ started following ECU BIN maps , Transmission recall service. , Starter motor repair and 3 others

-

Here's a link to a picture I posted of my gearbox in neutral before fitting the cover : https://www.v11lemans.com/forums/topic/20201-re-engineering-the-shift-spring/?do=findComment&comment=272756

-

See repair/overhaul advice here: http://www.largiader.com/tech/valeo/ http://bmwmotorcycletech.info/boschvaleostarter.htm http://advrider.com/index.php?threads/valeo-starter-refresh.954653/ You could also search this site for "valeo". You are not the first guzzi owner to have have starter problems.

-

Yes, I did that too. I got some genuine oil resistant hose, and found that it was too stiff to install. So the hose is used for coupling a sharp s/steel elbow at the front and a bent up aluminum tube further back. It works well and the uglyness is well hidden.

-

Nah mate, I bought one for my bike based on your recommendation. I just didn't say thanks. So thanks.

-

(ex) V65 Florida no start after changing headgaskets

MartyNZ replied to Tinus89's topic in Older models

Just for an experiment, can you try reducing your spark plug gaps? I have seen healthy fat blue sparks on removed plugs, but no fire when fitted. Compression pressure can be high enough to prevent a spark jumping the gap. The higher the air pressure at the plug, and the larger the plug gap, the higher the voltage needed to spark. Maybe the new gaskets have raised the compression pressure? I've seen a 1909 Fairbanks Morse engine run with a plug gap of 0.15mm (0.006"), but not with 0.63mm (0.025"). The weak spark from the magneto sparked a 0.6mm plug gap fine when removed. A V11 runs well with a spark plug gap of 0.7mm (0.028"), with 9.8:1 CR, because the factory electronic ignition delivers high voltage with high energy to each plug. Nippon Denso has some basic information on plug gap and compression pressure: Conditions that affect the discharge voltage | Spark and Ignition | Basic Knowledge | SPARK PLUG | Automotive Service Parts and Accessories | DENSO Global Website -

(ex) V65 Florida no start after changing headgaskets

MartyNZ replied to Tinus89's topic in Older models

Retorquing the heads alone shouldn't stop it from running. Could the ignition timing slip somehow? Does it have points needing adjustment and tightening? Or does it have a sensor that has picked up some metal particles? -

Crankcase pressure is always more than ambient due to piston ring blowby, however slight. This is unavoidable on all piston engines unless you have an unusual feature like a scavenge pump. For this reason, crankcase pressure will slowly build until it finds an escape path. If you block the vent going to the airbox, the pressure will rise until it relieves somewhere else, possibly showing as an oil leak. I don't think you should block that hose.

-

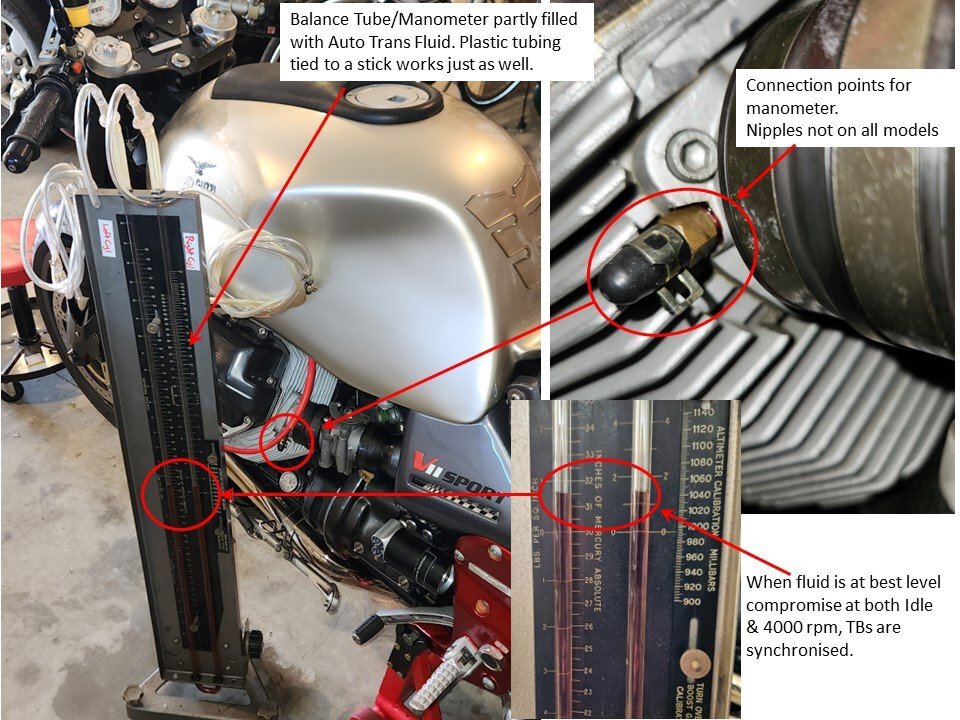

You can make your own balance tube tool to synchronize the throttle bodies if Scud doesn't have one. It is simple on a V11 because there are only two cylinders and two throttle bodies. I found out about this from an old post from 2003. How to build a water manometer - How to... - Moto Guzzi V11LeMans.com Forum See also :https://www.v11lemans.com/forums/topic/19610-decent-tune-up/?do=findComment&comment=233692

-

Polish lady Griso rider

MartyNZ replied to docc's topic in Special place for banter and conversation

Katarzyna Jaskulska. https://themotolady.com/katarzyna-jaskulska-wheelie/ @dangerous wrote an extensive commentary about her here : https://www.v11lemans.com/forums/topic/19384-gratuitous-pics-of-girls-guzzi/?do=findComment&comment=211626 -

Are you going to post some pictures of the project bike?