-

Posts

245 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by FreyZI

-

-

Manufacturer was doing a race in Vegas and very busy. I'll try to touch base with him this week. I left sample parts with him, so I thought I'd go back through Gettysburg and see him in the shop, take pics of carbon cloth options to post here. May not happen until I have a reason to go through there or a really nice day without responsibilities for a two hour ride each way. Still going to be a couple months... Planning on a batch of 12 to 15, with requested variants. Cheers, Frey

-

In other news, I finally landed on a center tank pad to cover up PO's crookedly applied pad and subsequent discoloration. The new pad hasn't completely resolved the problem, but it's better than how it was. Another benefit is that we know for certain what gender this bike is now.

-

Reservoir lid turned out great, right? Actually, the above pic of the lid is from just the right angle that it doesn't look like someone spilled a jar of raspberry jelly on it. This is what it really looks like: This coating will be stripped.

-

Stopped by powdercoater today to check out the new color: Prismatic's "rancher red" over silver. This photograph didn't capture it very well -- I think the color is very close. The question now is whether to put a satin clear on top. Think I'll take the Tenni out there tomorrow and compare. I'm thinking the satin.

-

What a difference a little piece of plastic makes: The aluminium one is going to the powdercoaters to get the candy apple red treatment with the pork chops for the Tenni.

-

Is that a hammer I see? So, I was driving past the powdercoater today and stopped in to see how they were doing with my porkchops. They have now stripped the chops three times because they can't get a good result. Gotta give them credit for trying hard. Hope to update on progress this time next week. I think they'll just shoot some scrap first. Good thing this is the spare set of chops and it's not going to keep the Tenni or Bubbles off the road.

-

Thanks for the explanation, docc. Gives me an idea...

-

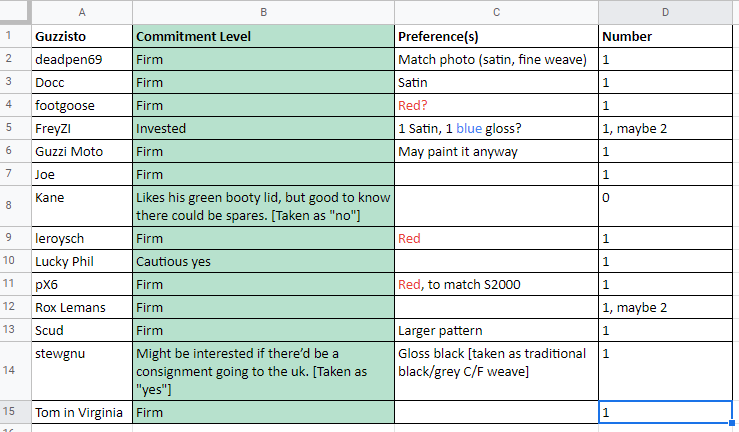

Turns out I have quite the mix: 1x1 large weave satin front fender, chin pad, side panels; 1x1 small weave hugger (a bit more sheen); 2x2 satin Mistral cans; and 2x2 gloss booty lid. Guess I can't screw it up too badly, whatever I do. Thinking the blue weave will look pretty sweet on the champagne (especially if I keep the gunmetal pork chops). Revised sheet to reflect @footgoose's happiness with his current black booty bonnet. @p6x, can I give y'all editing privileges? Maybe we will get Google "Sheet bombed"? https://docs.google.com/spreadsheets/d/1MG4LL0PE9ZBEyB7L9jmyZ16-ZkO3rMrBdcrVWVHjOmU/edit?usp=sharing Off topic (sorry), but @docc, where did you find those MG eagle oval badges on those Mistrals? My Mistral stickers are badly faded and I haven't been able to find new. Those badges would nicely resolve the problem (if they would fit oval cans -- I know yours are round).

-

Here's a link: https://www.vividracing.com/blog/1x1-vs-2x2-everything-you-need-to-know-about-carbon-fiber-weaves/ 1x1 looks like a checkerboard, 2x2 looks like diagonal stripes.

-

Good idea, @p6x. Here's a link to a Google Sheet:https://docs.google.com/spreadsheets/d/e/2PACX-1vRxzY1vqEMO45avvdnr-WqJcQYiXi14UHwDzr2MFGGgFc7XFzgc8oiuVYhcOXydhyPUZxUBOxQMTQbi/pubhtml?gid=0&single=true And here's a screenshot of what that sheet looks like as I have populated it:

-

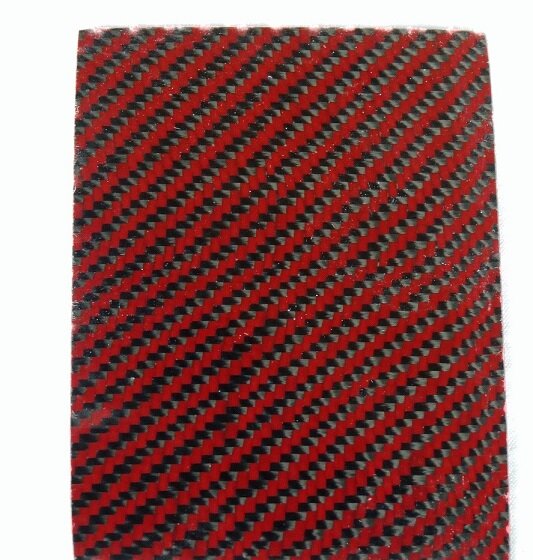

Thanks, all. @footgoose, check this thread back a page or two; I inserted a pic of the red from the fabricator's web page. There's also an orange if anyone wants to try to match orange cylinder head covers. Fabricator's website is riggeals.com. I believe they have pics of the swatches under the "custom" link. Greg was planning to get back to me Monday about the satin finish. If that doesn't turn out to be possible to our satisfaction, I'll think about red for the Tenni, too. We're still operating on estimates. Final pricing TBA. However, estimate for color Kevlar weave +$65.

-

Update: By my count, if I include @Lucky Philand @stewgnu (gonna do everything possible to share with brethren on the islands), we're up to 9 takers. Excellent! Way to open your wallets for purely aesthetic purposes! Given that number (and I'm counting on at least one more to chime in), there are enough on board to offset the cost of creation of the mold and prototyping and to get to a (subjectively) reasonable price per unit. I've gone ahead and told Greg to go ahead with the mold and prototyping. I haven't spoken with Greg about when payment is expected. I'll float the $550 mold and prototyping. I'll make up that investment with each member's contribution as the humps become available. Recall that we're looking at ~3 months before we have our parts. I'll plan to deal with logistics of distributing the humps, as safely and cost effectively as possible. Some (MD and VA) may be able to take delivery in person if desiring a reason for a ride to a convenient meeting point. As it will be some time before the mold and prototyping are done, I don't need your specific requests right now, but I'll be in touch with you all to confirm specifications. As the "not-gloss" finish will be at the end of production, its not critical to nail this down any time soon. Gloss is pretty obvious, but "not gloss" has some not-well-defined gradations between satin and matte. What I have been calling "matte" may be more like "satin". I'll get some pics posted of the "not-gloss" side panel I took to Greg for matching. Meanwhile, it seems that several of yinz want that "not-gloss" to match your Mistral C/F cans (which I presume are similar to mine). Again, not time sensitive: For those wanting the usual C/F/ look (whatever the sheen), 2X2 carbon twill weave (kinda standard). At the moment, I have +1 on red kevlar weave -- that is going to be sweet @p6x(BTW, HBD!). Thanks to all for your interest!

-

No, they would do the matte finish. Here's what Greg shared about the process, through my filter: The C/F parts that come out with a matte-looking finish are made with a vacuum process that pulls resin through the fiber, but also pulls a lot of the resin off the part altoghether, leaving a very thin part (possibly with teenie-tiny holes), but more susceptible to cracking. In a non-vacuum process, the resin remains on the surface of the C/F, resulting in a glossy finish. Thus, the application (by the fabricator) of a matte coating. I guess they don't have a lot of folks wanting a matte finish, but says they can do it (I left my vacuum/matte side panel with Greg so he knew what to match (for me)). It's a family business: Pops and daughter do the C/F work and son-in-law does the paint. Pops says he's really good.

-

Spoke with Greg today. 50% upcharge on kelvar/carbon color weave (currently available colors are red, blue, and orange). I suggested that there might be a couple folks with Greenies that would like a green weave, but he hasn't been happy with the green -- too yellow. Anyway, if he doesn't have the color in stock, he isn't going to order a whole roll of it. Matte finish to match mufflers, etc., would be by applied finish, not by vacuum method. The backing would be a carbon fibre-looking cloth (he says customers swear he did carbon backing, too) to add some structural integrity. As I mentioned, my existing c/f hump has fiberglass backing, so this should be an improvement if smooth and almost indistinguishable from the outside. @Lucky Phil, maybe there's a way to consolidate a couple items into a shipment to down under if you "need" other things from the States, too?

-

If color = red, but color red = +$65, then @p6x = 1?

-

FYI, From USPS: 1Effective Friday, March 11, 2022, the Postal Service™ will resume acceptance of the following services destined to Australia. First-Class Package International Service (FCPIS) Commercial ePacket (CeP) International Priority Airmail (IPA) Packets International Surface Air Lift (ISAL) Packets Customers are asked to refrain from mailing the following services to Australia until further notice: Priority Mail International (PMI) Airmail M-bags International Priority Airmail (IPA) M-bags International Surface Air Lift (ISAL) M-bags

-

Thanks, Docc. Looks same as my Mistrals (though mine are ovular). Looks like your V11 is collecting some images?

-

My assumption is that the mold can be used for whatever fabric is desired, be it carbon, kevlar, or fiberglass. There are a couple color options, too (red, orange, and blue), and I'd be checking out the red if I weren't trying to match the C/F on the Tenni. Here's a pic of the red kevlar weave with C/F. I imagine there would be some slight upcharge for colored humps. And maybe glass is less. I've seen a used OEM hump on eBay for $200. Prototyping the mold is going to cost $550. The more Guzzisti on board now, the more of us there are to share around that initial cost. If a few more people jump on this wagon, we can get C/F humps for less than $200 a piece. People who come to the party late will be insulted and subjected to indignities. . This forum has a collective engineering and fabrication tradition to uphold. One note: This part will not include the "rump bumper" -- that is the little vertical pad element. On the Tenni, the rump bumper is a little different, being covered in the so-called suede (which should, AFAIK, actually be called "rough-out" leather). The non-Tenni rump bumper is black injection-molded rubber. I don't know how hard it would be to get rubber rump bumpers made. I plan to cut something to size and cover it with black marine PU to match the seat, stapled on the back. Cheers, Frey

-

The website is http://www.riggeals.com/products/custom-work/ Obviously, I'll take a look at the prototype before pulling the trigger. Incidentally, my "humper bumper" has a fibreglass backing. Seems that's a good idea for durability of that part. I didn't get that far with Greg, yet.

-

Dropped some parts off at Riggeals this weekend. I took him my matte side panel (to match), my gloss hump, and an OEM hump. Here's the quote: C/F seat hump: Prototyping and mold = $550; each hump = $130. If 6 of us want humps, we're at ~220. If we can get a few more folks involved, we can get the price under $200 per item. Just in case anyone is interested, C/F side covers: Prototyping and mold $710; each unit $110. I didn't ask, so I don't know if the mold for the other side could be easily (cheaply) fabricated (assuming L and R are symmetrical). Possible we could get a discount if there are other parts Guzzisti on the motha of all V11 forums want made in batches (tank chin pad, fenders, etc.) We're looking at 3 months for wait and manufacture. We'd own the molds. I'm in on a seat hump if at least 5 others are on board. If we get that far, I'd need to know weave and finish choices. Likewise, @docc, may be worth putting out an APB calling all C/F parts wanters. Cheers, Frey

-

Incidentally, I asked Bruno "Brian" Saturno at G-B if he had any interest in making up the humps, too. He responded that he was happy to continue producing the Trofeo kits and creating a new "evolution" of the Sport Monza kit. He noted that the carbon belly pans, rear fenders, and wave discs are "always available". Cheers, Frey.

-

I'll come out and say that I'm not a big MM93 fan. He could use a dressing down like Ice-Man gave Maverick. Some arrogance is undoubtedly necessary to do what GP riders do, and deserved for MM, but some of his stunts (both en race and after) have been utterly stupid. Remember that idiotic arcade game stunt after winning the championship in 2018? I do give MM credit for taking massive bodily injury and getting back in the saddle and piloting a bike again and again. BBB. Time to retire, or do the VR46 thing? My guess is as long as he can command $20 million dollars a year in contract and endorsements, he'll stick around until his body quits. Unlikely that Honda will quit him. Anywho ... The crash in the Indonesia warm up was spectacular. Now, let me understand the dynamics of a high side: I found this definition of "highsider" on Wikipedia: Technical explanation[edit] Forces occurring between the motorcycle and the road (such as those that result in accelerating, decelerating and turning) occur at the contact patch through friction and normal forces. There is a limited amount of force tangential to the road that the contact patch can transmit before the tire begins to lose traction, and therefore slide or skid. When going through a curve on a motorcycle, centripetal force (added to the other lateral forces such as acceleration or deceleration) is transferred from the road to the motorcycle through the contact patch, and is directed at a right angle to the path of travel. If the net force is greater than the static friction coefficient of the tire multiplied by the normal force of the motorcycle through the tire, the tire will skid outwards from the direction of the curve. Once a tire slips in a curve, it will move outwards under the motorcycle. What happens from there depends on how well the rider is able to restore balance and control. If the tire regains traction after the rider starts to skid while the motorcycle is moving sideways, the tire will stop its sideways movement causing the motorcycle to suddenly jerk into an upright position (and beyond). This movement can easily cause the rider to be thrown off. [end quote] This makes some sense to my addled brain. Basically, a high side starts off like a low side. Then, either: 1) the bike tips further toward the ground, the tire patch evaporates, and the bike skids wheels forward-ish, 2) the lucky rider recovers just enough friction in the tire patch to return to equilibrium, or 3) the tire patch grabs and -- because the axis of the bike has turned too far relative to the direction of travel -- it acts like a fulcrum, turning the bike into a lever and the rider into the payload. In option (2) or (3), it seems that at the moment the tire patch grabs, the rear shock would be loaded. Then, it's a combination of the release of that load and the force (tangential?) from the rotation of the bike (upward/toward the outside of the curve) about the longitudinal axis that can either buck the rider out of the seat or cast the rider into the sky, a la Marquez. CMIIW. Assuming there's some reason to the above, what are the relative contributions of the unloading of the shock and the rotation of the bike? How would one modify their shock settings to allow high performance without setting the stage for a high side on accelleration? Cheers, Frey

-

Just spoke to a guy in Gettysburg who's been doing fiber and carbon manufacturing for decades (mostly dragster bodies). It happens that his shop is directly on a reasonable route for my upcoming trip, so I'll take an OEM hump, a matte carbon bit off the Tenni, and my current damaged carbon hump. I'll let you know what he quotes and then get a sense of what yinz all would want for options (weave, gloss/matte).