-

Posts

966 -

Joined

-

Last visited

-

Days Won

34

Content Type

Profiles

Forums

Events

Gallery

Community Map

Posts posted by Pressureangle

-

-

It's the transmission. Here's mine before the Caruso gears. I was a little disappointed that the gears are quieter than my chain was.

-

4

4

-

1

1

-

-

-

13 hours ago, docc said:

Just to clarify, you are referring to the internal gearbox shafts that carry the various gears inside the gearbox?

(To differentiate from the external "driveshaft" that carries the motive power from the gearbox to the final/bevel drive at the wheel hub.)

Yes, the clutch input spline nut, and the output shaft nut accessible after removing the driveshaft. I'm not at all familiar with the 6-speed to know exactly what's there.

-

12 hours ago, Walterg said:

Rolling the bike in neutral with or without the clutch lever pulled in makes no sound at all.

Rotating with and without the gearbox cover makes no sounds. Just the normal silent sound of rotating gears.

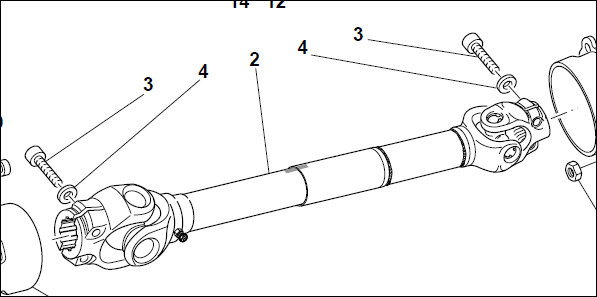

@Pete and Pressureangle: Just to be clear: With drive shaft you mean the shaft with the universal joints that goes from the gearbox to the rear wheel?

I'm asking because I don't see any pegs. Just two bolts per universal joint.I just made a simple clutch plate allignment tool so will continue with the disassembly.

Yes that's what I meant, but you're well past that. Despite the 'maintenance' items in your bellhousing, I'm behind Pete's simple suggestion that your shaft retaining nut(s) is not tight, allowing misalignment in the gearbox. Unless you've missed a broken tooth on a gear, it's just about the only possibility remaining.

-

...and as Pete says above, be certain the shaft retaining nuts are tight. On my 'Sport, the driveshaft has a spring to maintain a bit of pressure on the joints, I suppose to insure they don't walk off the shafts if (when) they get loose. If the output shaft nut (on 5 speed) comes loose, the pressure drives the shaft forward until the gears are so far out of alignment you can't shift them.

-

Here's a short video showing reassembly. Disassembly obviously is the reverse order of operations.

There is a tool to center your clutch discs without taking off your transmission drive gear, likely available from a vendor or member nearer to you.

-

1

1

-

-

My gut reaction is that your old oil filter left the gasket stuck on the ring, and either twisted out of the way unsealing the filter, or blew out when oil pressure hit it.

-

3

3

-

-

8 minutes ago, docc said:

Looking more like I should bring some razor wire and sleep next to my Sport . . .

I'mma gut an Omron relay and swap it in while you sleep

-

1

1

-

2

2

-

-

1 minute ago, docc said:

Now, a timing gear installation would be an epic SpineRaid Tech Session!

Game On

-

1

1

-

-

You're right, of course.

I have a corollary to Waddington;

"It ran when I shut it off..."

Bring the gears, they'll make nice centerpieces.-

1

1

-

1

1

-

-

I replaced my intake rubber boots today. Along the way, I bothered to do some discovery on best method, at least on my '97 Sport-i. The winner is Lucky Phil- taking the intake manifolds off is enormously easier than working the boots otherwise. I'm not even certain I could have installed the new boots at all without removing the manifolds; the bar that ties my TBs together is very close to the frame bracket for the transmission brace and wouldn't move back much at all. As it was, I removed the clamps, pushed the rubbers away from the manifolds, removed the 3 mani bolts, slid the rubber back onto the manifold and off of the TB. The mani and rubber pop right out with only a little fiddling and no force. Reverse the process to install. It's easier to install the mani bolts in their holes and place the rubber before working the whole thing into place; take care with the threads as you have to keep the rubber from pushing them around. Installing the screws last is difficult because you can't slide the rubbers back away very far. A ball allen is nearly demanded.

I had different gaskets on L & R sides. No info. Both sides stuck to the manifold and came off the heads clean. I cleaned the surfaces and put a very light coat of Permatex #2 to be sure they seal.

Reinstalled my throttle rod, synched the TBs, set the TPS and tomorrow a test ride. Idles dead steady at 1100 now. Again.

Those throttle rod knobs are still in the works, but they are a secondary priority behind real work.-

4

4

-

1

1

-

-

On 7/12/2022 at 6:58 PM, docc said:

Indeed. At 126,000 miles mySport has never run better. It tried to lift the front wheel on a hard second gear shift the other day.

On the original timing chain/tensioner.

I'm gonna need a good reason to take her off the road for the gear installation. And decide what other things to maybe do at the time. That can be a slippery slope: valves, guides, hotter cam, high compression pistons, polished rods, supercharger, water cooling, drive chain conversion . . .

Yet, I do have this gorgeous gear set for when the time comes.

Well, just think of the bashing I'll give you at the Spine Raid if your stock chain busts and bends all your valves and pushrods.

Just think of the bashing I'll give you at the Spine Raid even if it doesn't. Every time your steed hiccups I'll be throwing stones at you.-

1

1

-

1

1

-

-

3 hours ago, ScuRoo said:

If enough riding opportunities have been had & enjoyed

…are you guys planning on adding your impressions?

Made much difference?

I've said elsewhere that it's my observation that the bike starts easier, idles faster, never coughs or stalls, lost any hint of the ~3200rpm hiccup and generally runs better everywhere. That said in the environment of neglect, where I'd been sidelined by relay connections and a failed starter motor- the gears were a big improvement even then. I haven't had a whole good day at once on it yet since, but a couple hundred miles says it's great, and a *lot* of maintenance while awaiting the return of my throttle rod makes me very hopeful. It's my opinion that the stock chain tensioner simply does not hold timing well, particularly at idle and ~3200rpm.

-

2

2

-

1

1

-

-

That's a tough 'telephone diagnosis'.

Are there cushion springs in 6 speed clutch friction discs? Big trucks break those springs all the time. Could be a bit out of place, protruding just enough to clack against the flywheel.

-

Never had one in hand, but your lever *appears* to be forged, in which case it should be easy enough to have straightened and welded.

If you have the desire to overthink and overengineer, you could have one of these cut and welded on, or weld and machine your lever tip to accommodate the replacement tip only;

-

Check to see that both ends of your driveshaft are tight on the splines. I had a similarly disconcerting noise when pushing and found that my rear yoke was less than 'very' tight.

I have to add that I only discovered it upon disassembly, and I replaced the outer housing bearing; the 'rattle' was gone upon reassembly. So I attributed it to the drive spline coupling. Grab your rear housing to see how much play is in that outside bearing, also.-

1

1

-

-

I've been using Dissenter as my primary browser for near 2 years now, and I'm very happy with it. Dissenter is a version of Chrome, which is not owned by Google, rather Google has it's version of Chrome; Dissenter by default has pretty much everything turned off. If I want to research sensitive topics, I use TOR with a VPN.

https://www.linuxadictos.com/en/dissenter-el-navegador-de-gab-basado-en-brave-que-pretende-luchar-contra-la-censura.html-

2

2

-

-

On 7/7/2022 at 12:42 AM, footgoose said:

probably something on my end. affecting not just forum emails, though several recently have gone to spam. probably time to move away from google

I don't think there is any good unsurveilled email service. We were forced by regulation to use Microsoft Outlook for government business, and an attempt to forward an email through Gmail resulted in failure and notice that the data was protected; furthermore, a notification had been sent to the concerned party that an 'unsecured' communication had been attempted. It's game over guys, if you want secure comms, send a letter in invisible ink.

-

2

2

-

-

Tire shops, like most service businesses in the U.S., are hamstrung by insurance regulation and litigious customers; if they don't follow manufacturer's protocol they open themselves to lawsuits. Wal-Mart will not install single tires. No brake shop will pad your old rotors without at least turning them. No alignment shop will touch your car without nearly new tires. The list is infinite. Tire manufacturers 'recommend' installing new tire pairs, for instance, only on the rear of front-drive cars. WTF? Simple- front tires wear faster, so they get that second pair more quickly. Air conditioning compressor manufacturers require replacement, not cleaning, of other components or your warranty is void. The service environment is engineered to maximize the fleecing, whether it be your fleece by the service agent, or their fleece by the lawyers and regulators.

These are what economists call 'unwanted ingredients', and you pay for them everywhere.-

6

6

-

-

On 7/5/2022 at 6:28 PM, po18guy said:

Too bad it never happened - it would be a real source of spares.

Surely. Just as are the camshaft position sensors. I bought one from Romania for $18 plus about $25 postage. No Fiat model that used this sensor were exported to the Western Hemisphere.

-

1

1

-

-

I'd use an internal mushroom plug. If you don't ride the sidewall fast and hard, it's highly unlikely to be problematic. Even if it fails, it will leak slowly and you'll get something more out of it.

-

19 hours ago, gstallons said:

This air charge temp sensor is mounted in the post filter portion of the airbox . This location keeps dust , dirt , etc. off the sensor . This is to keep a true reading of the sensor.

you need to come up with a good cover to keep this stuff off the sensor .

This has me wondering if the real reason for moving the sensor into the airbox is to keep it dry, more than clean or in the perfect temperature (although all are served). I've never noticed any change when running wet or dry, but it wasn't on my radar either. I'll focus on that during the

Where nobody gets home dry unless they wimp out early.

-

1

1

-

-

I always install a Time-Sert in soft holes if it's been repaired, or even if it's a known point of failure and it's apart and accessible.

-

2

2

-

-

7 minutes ago, docc said:

Seems that would have been bolted to the airbox at one time (right front)? No matter where the air is picked up, the sensor would measure the temperature of the air inside the airbox?

Behind the fairing is the factory install on this early bike. My speculation is that somewhere along the way they found that airbox temperature was significantly different than 'outside' air, most likely sitting idling in heavy traffic. Add increasingly tight emissions requirements, and a simple change of venue for the ATS helped compliance, or at least made drivability/fuel mileage noticeably better. Can't know what the eyetalyun or European requirements were at the time.

-

1

1

-

Light rattle in gearbox when pushing my bike.

in Technical Topics

Posted

Ok, swinging a wild bat here.

Since there's no obvious physical damage or disorder, let's go back to the facts; the only time you have noise is *in gear when the clutch is rotating* correct? If I read the transmission correctly, there are 4 shafts- the output, 2 gear shafts, and the input or clutch shaft. It appears that both of the gear shafts rotate with the output shaft always; that would place the noise on or around the clutch shaft. Check your bearings, see if the cages have any damage or disarray. Does the input feel dead smooth when you rotate it by hand? Is there any detectable movement to the shaft, either radially or axially? Are any gear shifting devices located on the clutch shaft- sliding gears or sleeves, shift forks? (again I'm not familiar with the particular arrangement) Look to see that any engagement dogs are centered between their fore and aft partners, especially if they float on the gearshafts and rotate with the clutch shaft (not output shaft)

That should make a right mess of things.