JuhaV

Members-

Posts

99 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by JuhaV

-

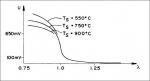

Hi, Here are a couple of response curves for normal, cheap narrowband lambda sensors. According to my experience (My16M in a Sport 1100i), it is quite possible to use even these cheap sensors for closed-loop and target for lambda 0.80-0.85 values (slightly rich, maximum power). I use lambda target voltage around 0.8 Volts in my bike. I would think, that you would not like to drive with lambda values > 1 in any circumstances even to improve the economy, because these engines do not run properly with that lean mixture. You will get hesitation, misses and all sort of "not nice" behaviour. Keep it rich enough and you will get a very nice and smooth power delivery. BTW, my bike uses around 5.5 liters/100 km. Some stuff about building a My16M ECU per Cliffs instruction can be found from : http://www.kolumbus.fi/koivupiha/ecu.htm br, JuhaV

-

Antonio, The side stand pic tells the story. Respect ! br, JuhaV

-

Al, You are so right ! Lets get back to more relevant issues. br, JuhaV

-

Skeeve, thanks for explaining this very relevant term to me And Antonio, because of you I needed to leave the comfortable couch, go to my garage, wash the rear wheel to get rid of the dust, and take a better close-up pic for you It seems that I am not able to lean over any further because of this thing : Now, please, so me YOUR rear tyre br, JuhaV

-

Antonio, This goes way beoynd my language skills Please explain what are those ? - JuhaV

-

Hi, That is a very interesting mod ! Need to try that in my Sport 1100. Al, if you start up mass-production keep me informed br, JuhaV

-

Here is my "self-made" modular hydaulic lifting system. I think that you get idea when I tell you that those bottle type hydraulic jacks cost about 10 dollars per piece (at least here in Finland). With these you can lift the bike from whatever point , for example, fork or frame tube . I only added (by welding) the U-shape brackets and the support plates and their attachment means. Works fine. br, JuhaV

-

Hi, Is it this one : http://www.aep.bigstep.com/digital1.htm br, JuhaV PS. In a newer FI guzzi you need in practise to have Power Commander to adjust CO. Some small stuff can be done with the airscrews or perhaps TPS adjustment, Older ECUs (16M) have a trimmer to adjust CO in 0 - 3000 rpm range.

-

Hi, To be sure that the butterfly is fully closed for the 150 mV adjustment, I always remove the plastic air inlet tube from the injector body and take a look inside. I also run with the air screws in fully closed position. br, JuhaV

-

Try these : http://151.38.134.156/cdguzzi/ http://www.uni-kl.de/FWT/fhb/fhb.htm br, JuhaV

-

Hi, Lets assume for a while that a windage plate itself will not cause any lubrication problems, but the lubrication is really taken care of by the pressurized oil feed travelling through the crank, cam, rods etc. Some of this oil (after exiting through the bearings) will splash around to lubricate cam chain and otherimportant items before returning to the sump. In other words, we do not need any oil splashing directly out from the sump to lubricate anything. Sounds reasonable, right ? Then, next question is that can a windage plate really free up some hp ? If not, it will only add some weight and that is bad For simplicity, lets assume now that the outmost parts of the crank are travelling around in a circle having 20 cm diameter (10 cm radius). This gives us a circumference distance of approximately 63 cm (2*pi*radius), if one thinks the smallest circle inside which the crank could turn. Engine running 5000 rpm, this means that we a peripheral speed of 0.63*5000 m/min = 3150 m/min. This equals to 52.5 m/s. Ok, 1 m/s equals 3.6 km/h. Now we see that 50 m/s = 180 km/h !!! This means that at 5000 rpm the outmost parts of the crank are travelling faster than 100 miles/h. If those parts move repeatably and closely over the surface of hot oil in the sump, it seems that the vortex created there can really lift some of the oil airborne and cause foaming etc. Imagine any object (with that size) passing by your face less than 10 cm away and having speed > 100 miles /h. The airborne oil will also surely create a drag / resistance when moving the crank at that speed. This might at high rpms require a noticeable amount of hps to be overcome. It seems that the benefits of a windage plate could be maximized by locating it as close to the crank as possible, but this is technically quite challenging in a guzzi. Still, some clear benefits could be there just by covering the sump in a way Enzo's plate is doing. br, JuhaV

-

Hi Chris, I do believe that you can figure out your tuning that way. I have been doing that with Cliff Jeffries My16M ECU and Optimiser-display that allows me to see the lambda-probe reading (and also a lot of other stuff) in real time. I only have a narrow-band lambda probe, but it seems to be sufficient to see if the mixture is approaching stoichiometric, which is too lean if you are looking for power Driving around with the probe helps to see where I need to adjust the map. After some iterations you will get the map close to perfect. And what is important, you will get the map correct for normal riding situations, i.e. those rpms and TPS-values that you normally use. If you have a Powercommander + wideband lambda-probe with display (and preferably also with datalogging) you should get there. It will take time and consideration, though. I wrote earlier in the "Roaddyno" threat the following : "What confuses me here is that according to my understanding most of the dynos out there are inertia type dynos. These are more or less "accelerometers" that allow to measure the rwp and torque during a full throttle acceleration. This kind of dyno "simulates" the real life situation when a bike is accelerated from idle to red line with throttle wide open. The other type of dynos are brake dynos that allow the bike to be kept under certain steady state load and rpm conditions. Changing the load and rpm one can check different parts of the map. The question is : How do you actually check the partial load and throttle conditions using an inertia dyno ? These conditions would be those normally applicable during normal riding situations. In dynojet dynos, do they make several accelerations with different throttle settings ? What is usually shown, are only those curves where throttle has been wide open -> max. power & torque" I hope that somebody could clarify this, because otherwise I will maintain my current believe that inertia dynos are mainly good for checking max power with max throttle. br, JuhaV

-

http://www.widebandcommander.com/ Dynojet seems to also offer one system. br, JuhaV

-

[Enzo, If the plate will fit a Sport 1100, I will be interested too. I have a slight hesitation, though, thinking about those possible items that the oil mist is supposed to lubricate ? Could you kindly provide a list of ALL mods that your bike currently carries and the latest dyno recording ? I am not yet able to picture clearly a guzzi that lifts the front end without heavy misuse of the clutch. br, JuhaV

-

Mike Rich Motorsports Hi-Comp Pistons

JuhaV replied to al_roethlisberger's topic in Technical Topics

I will do that during the winter. I already measured the fuel pressure with the original regulator and found out that I have been running slightly underpressured. I am going to install a pressure gauge to the bike permanently to make the adjustments easier. - JuhaV -

Mike Rich Motorsports Hi-Comp Pistons

JuhaV replied to al_roethlisberger's topic in Technical Topics

Al, Forgot to ask, are you going to hone those nicasil cylinders somehow before installing the pistons ? I think that nikasil plated cylinders ask for some kind of special procedure (ball honing ?) for this. br, JuhaV -

Mike Rich Motorsports Hi-Comp Pistons

JuhaV replied to al_roethlisberger's topic in Technical Topics

Hello Al, I also purchased Mike's pistons, mainly because he kindly and promtly answered all my questions in a very convincing manner Something that the FBF people did not for some reason bother to do Mike's pistons (manufactured by Ross pistons) should optimize the squish-band heigth without need to use non-standard cylinder bottom gaskets. The manufacturing quality of these pistons is very high. I myself also like the shape of the piston skirts around the piston pin ends with those recesses minimizing the contact area/friction. The 1st and 2nd piston rings are very narrow further minimizing the friction and mazimizing the sealing. Keep us posted when you get your bike on the road with these pistons. For me, it will take something like 6 months before the weather allows riding again. br, JuhaV -

Hello again, I am not yet blocked into the garage because of snow, but yes, the driving season is really over now here in Finland Temperature seems to stay around zero Celsius and the snow will be there any day now. Anyway, winter time is kind of good (=positive thinking) because there is no immediate hurry to get back on the road. So, some hardware modifications will most propably take place during the next months. I already have Mike Rich hi-comp pistons waiting to be "dropped in". The heads will be mildly ported to smooth the flow characteristics. Then, I also consider modifying the fuel pressure regulator to raise the fuel pressure from 3 bars up to 3.5 bars or something. This is because I seem to be already approaching the limit, where I cannot anymore add the pulse length for fuel injectors much more. I have Cliff's My16M and have done over 10000 km with it this summer. This was the first big modification to the Sport that I chose to do, mainly because it allows me to freely adjust the fuel and ignition maps to cope with whatever other modifications I might have. I run the My16M closed loop with a lambda sensor. I am very happy with this unit, because it really transforms the whole behaviour of the bike compared to the original Weber Marelli unit. The response to the throttle is really nice and sharp and the bike also idles smoothly without trouble. Back to the original subject. I can understand that the Veypor unit will surely not replace real dynos with gas analyser capabilities, but I can see that it might provide better sensor than my own ass to compare the effects that my modifications have. An important point is also that those measurements might be quite repeatable, if the same instrument is used every time in a similar manner (same air temperature, same weather/barometric pressure, same piece of the road). Cliff, you are absolutely right here, but have you solved the problem how to get equal sample intervals during datalogging, or alternatively, how to get an exact time stamp for every sample in case they are unevenly distributed in time ? The datalogging rate 7-8 samples per second (My16M) is quite enough to make reliable measurements. If this can be achieved, then Veypor unit does not provide anything more than one more nice blue display to look on. Unfortenately, my datalogging device does not allow to have a time stamp for those events, so it would be nice to get it from the My16M. Or maybe there is some terminal emulator or other program suitable to be used in a laptop PC to datalog the My16M dataflow and stamp every line with time info ? br, JuhaV

-

Hi, There seems to be at least the following items related to this discussion : a. the dynamometer (to measure rear wheel power, inertia or brake type) b. the lambda-meter (to measure the A/F ratio and included in the dyno, or in a Wideband Commander, or in a closed-looped ECU system) c. an adjustable fuel injection system (having ECU + Powercommander, or having My16M/My15M, or having Ultimap or some other way to adjust the map) To fine tune your bike you will more or less need to have all those items a, b and c. What confuses me here is that according to my understanding most of the dynos out there are inertia type dynos. These are more or less "accelerometers" that allow to measure the rwp and torque during a full throttle acceleration. This kind of dyno "simulates" the real life situation when a bike is accelerated from idle to red line with throttle wide open. The other type of dynos are brake dynos that allow the bike to be kept under certain steady state load and rpm conditions. Changing the load and rpm one can check different parts of the map. The question is : How do you actually check the partial load and throttle conditions using an inertia dyno ? These conditions would be those normally applicable during normal riding situations. In dynojet dynos, do they make several accelerations with different throttle settings ? What is usually shown, are only those curves where throttle has been wide open -> max. power & torque It seems that in an inertia dyno two bikes could actually produce quite similar hp and torque curves, but in real life the seat-of-the pants driving sensation could be very much different. Some stuff regarding dynos can be found from http://home.iprimus.com.au/stevebm/Dyno_Info.htm Please, those familiar working with dynos, share some light to this subject. br, JuhaV

-

Hi there ! Take a look at http://www.veypor.com/ That seems to be a kind of a "road dyno" to make performance measurements by yourself without taking the bike to a dyno center. Even if one propably cannot expect fully accurate absolute rear wheel power measurements, that might be a good tool to make comparisons between any engine and/or fuel map modifications. Unfortenately, lambda-sensor input is missing, so mixture adjustments need to be performed using the well-known trial-and-error method. Any experience among guzzi people about that gadget ? br, JuhaV

-

You have 45 hp at 3500 rpm, not 78 hp. However, very nice curves anyway. A lot of torque and power already at low rpm. The top end does not look bad either. BR, Juha

-

Terve Søren, Well, it is something like this : Longer story can be found here My16M is a replacement for Weber Marelli 16M developed by australian Cliff Jeffries. BR, Juha

-

According to my understanding new Guzzis run closed-loop below 3000 rpm, that is, in cruising speeds. Above that they go directly according to the fuel map and do not use the lambda sensor signal for adjustments. If you disconnect the lambda sensor, the ECU will go open-loop everywhere in the rpm range because it cannot get any reasonable lambda signal. So, if you want to enrichen the map below 3000 rpm, you need to disconnect the sensor. I got this info from a reputable Guzzi mechanic, but have not tried that in practise because I am myself driving a My16M powered Sport 1100i BR, Juha

-

Well, I am most propably going to try those Mike Rich 10.5:1 pistons in my Sport Corsa 1100i. For one thing I aim for the higher compression, but also for better defined squish band height and more optimal combustion chamber geometry that comes with those pistons, as I have understood. The latter two are also important when trying to avoid pinging. Modern motorcycle engines with fuel injection have up to 13:1 compression ratios without any pinging problems. I kind of think that quite reasonable 10.5:1 should not be asking too much even if it is an aircooled one. With correct mixture, I am quite confident that pinging or overheating will not be significant problems. BR, JuhaV