-

Posts

20,501 -

Joined

-

Last visited

-

Days Won

1,189

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by docc

-

I've moved the Neutral Switch mess I've made off this thread to Tech Topics. Thanks for helping me figure out what happened! [edit/July 31, 2021: one of the circlips failed to stay in its groove and allowed the cam wheel to shift inboard where it did not contact the neutral switch.]

-

ANSWERED Neutral switch stays on after assembling shift plate

docc replied to MartyNZ's topic in Technical Topics

Moved these posts here from the Lucky Phil V11 Shift Improvement thread in "How To . . ." Thanks, y'all, helping me figure out what I've done . . . -

ANSWERED Neutral switch stays on after assembling shift plate

docc replied to MartyNZ's topic in Technical Topics

I tried to make sure the clips were seated in their grooves and spun them with a punch tip to verify. Still, my plate has the "banana plate" that gets a second clip. (The other 13s in the upper right inset.) The banana plate screw, 36, was really hard to remove and retighten, requiring heat. I wonder if that process backed out #20 lifting the assembly away from the switch plunger . . . [edit: #20 looks nutted on the outside of the plate. Hard to imagine I loosened that.] [edit2: that nut feels tight. No leaking around it.] -

ANSWERED Neutral switch stays on after assembling shift plate

docc replied to MartyNZ's topic in Technical Topics

I can only suspect that the outboard flange of the lower cam wheel is against the pawl arm where that arm should seat in a groove between the inner and outer plates of the cam wheel. I just would not think the seeger rings would capture on the shaft if that were the case . . . And that the gearbox just would not shift well at all if it were jammed together like that. -

ANSWERED Neutral switch stays on after assembling shift plate

docc replied to MartyNZ's topic in Technical Topics

Nope, did not move the switch in the process. So, the switch closes when the plunger at the tip has no contact (sits in the detent). This turns the light on (and pulls in the middle relay). My switch tests good. The very slightest pressure on the plunger opens the switch (light out). I can see my detent lines up perfectly in neutral. The gearbox shifted perfectly today (notably better, even!) through all gears (205 miles) and clicks cleanly into neutral. All of the "Seeger rings" clipped onto the selector plate shafts. It is as if the "toothed wheel" of the selector plate is too far from the switch to touch it, so it stays closed as if it were in the neutral detent. I really don't want to open it back up. Worse, yet, I cannot fathom what could have changed . . . [edit: I tried installing the switch with no crush washer with no change. It does not appear to be touching the wheel. I also backed the switch out considerably and it stays closed, no pressure on the plunger. I had not removed the switch when the plate was removed for the sealing and roller bearing.] -

The other two springs (both Moto Guzzi parts) superimposed showed the compression of 90,000 miles:

-

Top: 64,000 mile factory pawl spring; Middle: new factory spring; Bottom: ChuckScud Superspring:

-

I have a couple posts to report after doing (most) of the Lucky Phil Shift Improvement. First, though, a big thanks to @Lucky Phil for sharing the technique and posting such great detail! My box shifted okay before, but definitely improved. My shift lever had been sticking down periodically, so I replaced the springs (along with the Chuck/Scud Superspring). Unfortunately, the sticking persisted after the new springs. And the plate did not seal upon reassembly, so I had to go back in. This time I changed the leaky shifter shaft seal and installed the McMaster-Carr roller bearing posted by @Craig back in 2016. Today, 205 miles, no leaks! And the new roller made my shift feel decidedly smoother and more precise. And no lever sticking! My original bearing was really peckered up as you can see in the image. It was grooved like this in several places around the surface: Yet > sigh < , my neutral switch is stuck on and I really don't want to go back in there. (I sealed that cover REALLY WELL this time.)

-

+1 on the Clutch Lock-out switch, or its wiring/nefarious bullet connectors having been affected by the tip-over . . .

-

Well, on a steady state throttle, as in rolling down a freeway, I have seen as much as 40 mpg and am confident my tank will deliver five US gallons (maaaaaybe 5.1). So, sure, 200 miles in those conditions. Yet, I absolutely love-love rowing this gearbox and ripping up-and-down through the revs. I am total hell on tires and brakes and fuel economy. On a chilly day when the weather feels like the Sport is climbing the Stelvio pass, and I'm pretending to be Omobono Tenni, I can see as little as 32.5 mpgUS. But it's worth it . . .

-

Yes, compared to the other "warning lights", the Low Fuel light is much more likely to sneak up on you and stab you in a kidney because you weren't watching the elapsed mileage. I watch for mine to flicker an intermittent *glow* at about 138-145 US miles. Then it goes out. Maybe glows again at idle or very low throttle (opening the throttle cools the sensor with return fuel and extinguishes the warning light.) Early V11 tanks and later (internal pump/filter) tanks differ, but the actual expected range may not be much different . . . 165 to 175 and I'm on the roadside doing the Left-Tip-Slosh-Get-Me-There drill . . .

-

Anyone enthusiastic about the V11 will likely be comfortable at a South'n SpineRaid. We hardly ever scrounge parts off Norges. But, mebbe . . . Rooms left at The Lodge? Dunno at this point . . . There is a motorcycle campground very nearby, and often SpineRaiders at The Lodge might have a wee space to share a bunk. Comes down to: Get There. Bring Tools.

-

Seven weeks to the Seventeenth South'n SpineRaid. Might as well flirt with Waddington . . .

-

Truly. An important distinction between "wobble" ("tank slapper") and "weave" (that some early V11 were prone to at high speed with lateral air blast like passing a semi/tractor-trailer rig). Increasing the steering damper damping worsened the high speed weave (without benefiting the absent corner exit "wobble".)

-

“Form A” is the 4-pin and suitable for all V11 positions except the front/ #1/ Start Relay which requires the Form C/5-pin. The conventional wisdom has been to simply source all Form C/5-pin as they can be swapped into any position needed. If I were to mix Form A and Form C in my relay stack, I would mark them in some way to avoid swapping a Form A/4-pin into Position #1.

-

-

The steering damper is so very easy to check. Be certain it is turned all the way counterclockwise. (Note where it is currently set.) IIRC, your forks only have compression damping. Easy enough to turn the adjusters in and count "clicks", then all the way back out to record where it is set now. Simply return it to the current setting before deciding to change it later. Changing the preload on the rear shock is more involved as the tank and airbox may have to be removed for access to the lock rings.

-

This is less so on the earlier "ShortFrame" V11. I found that once I had selected fork and shock springs for my weight and "sag", and biased the sag more toward the front, I get the best handling moving forward "behind the tank" and weighting the front. One of the simplest adjustments is to be certain the steering damper is backed completely off (set to the least damping).

-

ANSWERED Installed new battery, spins over but won’t start

docc replied to Taxguy's topic in Technical Topics

I can speak from substantial experience and close personal knowledge that any silver V11 Sport which has sat for ten years due to electrical issues is wanting for one key solution: V11LeMans.com -

Makes me feel rather scolded. "What is a small and puny ant, like you, doing hanging around Muscles Mahoney's Gym, anyway?" Seriously, we are the largest collective V11 community in the world and no one here has used this lift?

-

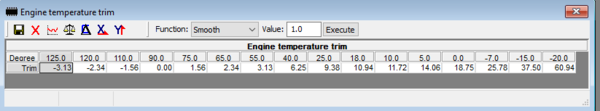

Interesting. I tried that, also "back in the day", only discovering later that my Sport responded markedly better to the exact opposite (low mass Engine Temperature Sensor Holder modification). Differ'nt animules, we all is.

-

ANSWERED Installed new battery, spins over but won’t start

docc replied to Taxguy's topic in Technical Topics

-

ANSWERED Installed new battery, spins over but won’t start

docc replied to Taxguy's topic in Technical Topics

Or on the grounding side. So many ring terminals, so little space. So easy to drop one on a battery change. Very happy the "revisit" yielded the desired outcome, @Taxguy