-

Posts

4,632 -

Joined

-

Last visited

-

Days Won

240

Content Type

Profiles

Forums

Events

Gallery

Community Map

Posts posted by Lucky Phil

-

-

3 minutes ago, docc said:

And your frame will connect a center spine plate to the front of the gearbox?

Yes docc, I'm running the extra plate.

Ciao

-

1

1

-

-

A Dayton/Centauro and I would then assume an MGS-01 all run higher oil pressure than the V11 engine by virtue of its higher relief pressure setting.

The Caruso oil pump has the potential to support pressure by virtue of its greater pumping volume. It also means that it can cover system losses better if things get to a dire stated internally for whatever reasons.

A friend of mine had a relatively new MK4 Le mans years ago that would put the oil pressure light on in the summer at idle once warm running one particular grade of oil which I cant remember now. It was ok with 20W-50 under the same conditions though. I have always though that maybe the Guzzi engine is a little marginal with oil pressure at low rpm and high temps, Maybe.

Ciao

-

10 hours ago, Tinus89 said:

That lowest/most right corner is where my gearbox cracked...

Ok good to know. I didnt realize they cracked there as well. May need to do some blending there also or remove the whole corner as luhbo mentioned.

Ciao

-

1

1

-

-

12 hours ago, luhbo said:

On my actual bike I have done nothing of the above discussed modifications and the gearbox is still good after at least 80.000 km.

My first one was already sipping when I bought it with 30.000km in 2004. With 200.000 11 years later it did still the same, a few drops per day. Never had to refill any oil.

Based on that the most important thing is to not overtighten this mounting bolt I'd say. Besides that the mentioned tube mod is done quite frequently over here.

Ok didnt know that. I think I'd still go with a tube insert between the lugs and leave the metal in the holes. Seems the cracking is a bit hit and miss but better to address it if possible. I would go all out if I had the equipment of my machinist friend was still local to me but hopefully the extra gearbox support and radius will be enough to mitigate the risk.

Ciao

-

3 hours ago, sp838 said:

Heh, funny, I remember a few years ago you were giving me shit for using Ti fasteners, saying I was wasting my money. Good times!

Really? Proof?

Ciao

-

Stainless Steel is a poor choice for fasteners on a motorcycle esp one that vibrates a bit. The material is too hard and so has minimal stretch which leads to loosening fasteners. they were made for the marine and building industries not for automotive use.

I hate the way passive cad plated steel fasteners dull after a while but I wouldnt go SS. The Daytona engine I have just completed and the gearbox I have apart on the bench have been converted to all Titanium external fasteners including the washers. I guess the engine cost around $230AU or so to do and the gearbox around $140AU. Ti fasteners dont weather, stay tight and look great for the life of the bike or car.

All my bikes have gradually morphed over to Titanium fasteners including the chassis bolts and nuts. The cost is up there I know but I think its worth the money in the long term.

Ciao

-

1

1

-

1

1

-

-

8 hours ago, luhbo said:

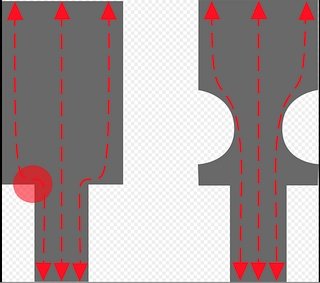

On balance I think I'll leave it the way it is with just the radius done. The above is interesting and I understand the concept but its not quite applicable to the V11 gearbox mount in that no matter what the loads will go through the radiused area. No ability to create a modified load path. To give a lateral steel bush any meaningful wall thickness you would need to open up the mount holes 4mm which I think would be too much but the idea is sound. What you could do is use a tube between the inner faces of the mount lugs that the bolt passes through which would achieve the same results with regards to the crushing/squeezing loads from the bolt. However that would require machining the inner faces of the bosses to square them up and I dont have access to a mill at the moment.The lateral ribs between the mount lugs are also at bolt hole center line as well which will take the mount bolt crush well enough I think on balance.

Considering the occurrence of gearbox cracking, the mileage at which it generally occurs, the fact I now have the supplemental gearbox mount and have done the radiusing and the low mileages I actually do I think as I said I'll leave it there. All good suggestions though and worthy of consideration for those with the box out and access to the machining equipment and the prospect of lots of miles.

Ciao

-

-

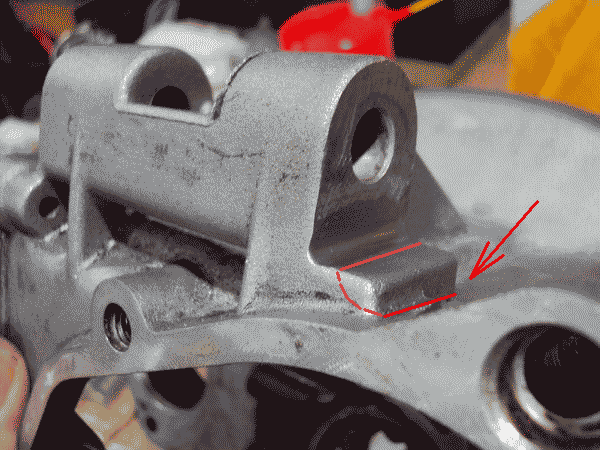

So here's the gearbox mount rework. 4mm round file and take it carefully. Finish off with some 800 wet and dry on the file followed by green Scotchbrite.

Important to make sure the finish of the fillet is smooth and free from surface defects that may cause stress risers.

Ciao

-

1

1

-

-

1 hour ago, swooshdave said:

Without a doubt, but with all things there's a cost/value question. The question would be what else could I spend the $700+ on as the stock pump probably won't fail. So it comes down to your priorities and funding levels.

I take all the points made but as the old saying goes, long after you've forgotten the cost the quality remains. I btw didn't replace my V11 pump when I did the gear upgrade. I didn't realize Joes pumps were available and there was some fitment issues due to patchy quality of some aftermarket pumps around that time so I stuck with the std pump. I did however use a DHS pump I'd had for years in the Daytona rebuild.

Ciao

-

36 minutes ago, sp838 said:

lol, looks like someone has been reading Zen and the Art of Motorcycle Maintenance, perhaps taking it a little too closely to heart. As I said up thread, I understand the value of better engineered parts. There is such thing as "gilding the lily" though. Quality for quality's sake is nice, but personally I'm more pragmatic than that. I want performance or longevity improvements for my money. I'ld happily plunk down the cash for an oil pump hand whittled by Leonardo Da Vinci, raised from the the dead, crafted lovingly from a solid block of platinum, but only if there was an actual measurable benefit for it. But if the stock Guzzi pump does the same job, despite being uglier or less refined, then it's staying. I'll spend my money on something else. Like a nice paint job.

I think I covered the benefits of Joes pump adequately.

Ciao

-

How about one of these. Year model 2003 1000ss Dual Spark

Or in this guise.

Ciao

-

1

1

-

-

I thought before I get too far into this gearbox stripping and painting I'd better check that the mounts weren't cracked.

First step break out the dye check kit.

Clean down the mount area and apply the dye. Wait for 15 minutes.

Clean it off again with solvent and apply the developer. All good thankfully. Its not hard to see why they can crack here. There is not genuine radius from the vertical machined face to the horizontal area. its just the edge created by the face cutter. I'll create a radius here by hand as there's a decent amount of material and what you lose will be more than compensated for by the removal of the stress raiser from the machining.

Ciao

-

4

4

-

-

1 hour ago, docc said:

I, too, am back to the nut side.

(Some would say I never left . . .

)

)

Nut side, not that its going to make much of a difference.

Ciao

-

5 hours ago, sp838 said:

I'm still unclear as to what this pump does differently or better than the stock one. I have a set of the Caruso wheels, am planning on doing the swap at the end of the season. I understand the value of better engineered stuff, but "better engineered" has by definition a set of criteria and metrics by which you can say it is better. So other than the craftsmanship that went into making it, what does this pump do better than the stock one? Is it longer lasting before it wears out? Does it pump more oil? The difference in idler gear, for instance, what is the benefit of that?

The original pump isn't going to fail but as has been mentioned the pump from Joe is better quality and addresses some issues.

Most of the answers you are looking for are in the images. The pressed in steel support for the idler gear means the gear runs on a hardened steel shaft and not a gear supported on an integral shaft running in an alloy housing. The gear is better supported and the housing wear is eliminated as shown in the images. Some of the internal housing wear can be due to the minimal support of the original gear and a combination of wear between the shaft and the housing bore allowing the gear teeth faces to contact the housing internally causing damage which reduces oil pressure. Having the shaft rotate in the housing also means you lose oil pressure through the clearance between the shaft and the housing bore.

Joes pump will last longer than the std pump and will pump slightly more oil due to less losses. Joes pump I believe also uses the later Daytona/Centauro/MGS-01 21mm wide pump gears as apposed to the 16mm V11 gears which means it has the highest volume oil pump of all the big block engines. So better, quality, higher volume, less losses and better durability probably sums it.

I guess at the end of the day most people fall into 2 camps, those that think quality has value for its own sake and those that dont. Its a bit like people that pay big money for a beautiful original looking custom paint job without any orange peel etc. It has no practical value and is going to cop damage etc from road use but they still want and appreciate the quality.

Individual value systems.

Ciao

-

2

2

-

-

3 hours ago, swooshdave said:

Do you have to use the new pump with the gear drive? Or is it an optional extra?

No I fitted the gears to my old pump but Joes new version is far superior to anything else out there I believe. His pump has the idler gear running on a steel shaft like a Ducati pump instead of the shaft being incorporated in the gear and it running in the alloy pump housing.

The whole upgrade is about quality improvements as Mikko outlined and that's exactly how I feel about most mods I undertake. Its an opportunity to correct the cost cutting and quality short cuts of a mass produced piece of engineering. It will never equal a factory race bike of course but its an interesting and satisfying engineering path to go down all the same.

Of course you could always start with something truly horrid in design and engineering terms like a Norton Commando or a Triumph twin but lets face it nobody wants to waste that much time:)

Ciao

-

3 hours ago, Mikko said:

I asked Joe if there was anything else I should concern myself with since I’ll be in that general area fiddling with stuff. Here is what he said:

Two things I would check is

1- the bronze camshaft thrust spacer which should measure 7mm thick and have no wear ridges in it.

The upgrade flange is like in the picture attached with the 3 oil cut outs and I can supply if you require one, and this gives better lubrication and so wears less.

2- The oil pump requires checking that there is no play in the bearings before mounting the new steel oil pump gear so it runs true with the crankshaft gear.

Depending on the mileage of your oil pump It is also worth checking for the wear points as in the picture attached. If required I will also be making some new CNC oil pumps to complement the new steel timing gear sets similar to the picture attached.

I won't know the cost of the oil pumps until they are completed but you can decide when ready should you require one.

I will be in touch near the time when I have a better idea of delivery date but I am guessing it will be around the end of September/October.”

I covered this in my Joe Caruso timing gear install thread. Dont bother checking it just fit a new one. Tip....you can buy the old version much cheaper than the updated version and simply die grind the oil feed slots yourself in about 5 minutes.

Ciao

-

3 hours ago, luhbo said:

You're missing the british gear towers

Nonetheless, I think the times of gears were over once the chains were reliable enough.I think the days of gears were over once accountants and not engineers started running businesses.

Ciao

-

1

1

-

-

7 hours ago, gstallons said:

I will never forget the first time I heard a gear drive set-up in a engine …. Yeow . I thought George Thorogood was inside of that V-8 !

The noise from gear drives varies depending on many factors including engine harmonics but also mesh clearance cold and hot. I've had engines that wine when cold and have a slight clatter when hot. As the alloy crankcases heat up and the bearing centers that support the gears move away from each other the whine caused by tight clearances dissipates and is replaced by gear backlash noise. depending on many many variables is the volume of noise in hot and cold conditions.

I was in the pits back in 1988 at Oran park round of the WSB talking to Robert Dunlop who was riding a Honda RC30 that year as a privateer and hung around to hear it start up before the first race. That was the first time I'd heard an RC30 with the backlash gears removed and it was quite noticeable. Although Honda would have run a decent amount of tooth clearance and relied on the backlash gears a fair amount as it was a production engine system. I owned an RC30 at the time so was interested in what modifications he was running in WSB.

The list of engines that have used cam gear drives is like a who's who of brilliant engineering. Manx Norton, bevel drive Ducati, Guzzi V8, ahem...the Guzzi big block V twin and of course the venerable Rolls Royce Merlin.

If anyone needs any more convincing after reading that list I cant help you

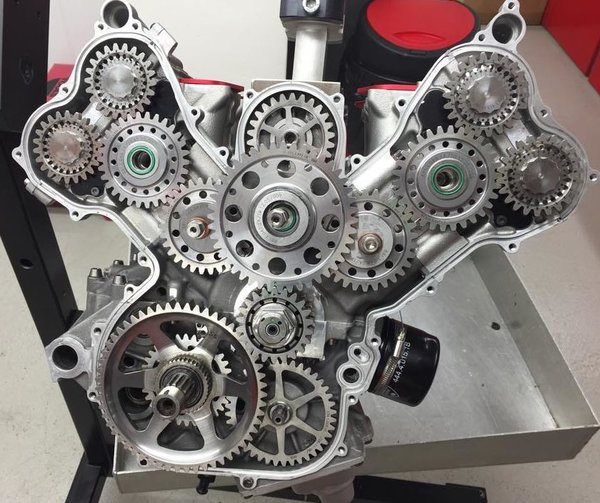

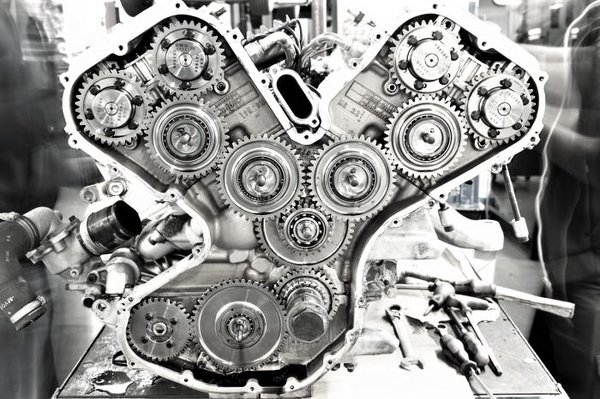

Hears some engineering art to ponder.

Ducati Desmosedici V4RR

Ferrari V12

Ciao

-

3

3

-

-

2 hours ago, gstallons said:

Ah , we're from the same time zone ! I don't think they would have used a round retainer .. a lot of Japanese bikes used to use a round retaining ring w/a 90 on the end so you could get them off . the best method is a snap ring w/eyes on each end . Anyone that has worked on one of these can chime in and clarify . BTW There is no way that ring can out of the cylinder .

The Daytona I've just assembled and just about every engine I've worked on over the years including Ducati race engines has used round section wire retainers.

Button retainers that I've seen were generally used on drag racing engines.

Ciao

-

3 minutes ago, docc said:

The new "inner spacer" (the short one between the drive side wheel bearing and the reardrive carrier bearing) is 0.002" shorter than my original. The outboard race for the needle cage (in the right side of the reardrive next to the swingarm) is 0.001" longer than my original. I'm thinking these are within tolerance (?) and I'll install all the new parts I can.

Looks fine docc. Fit up the new stuff as you said.

Ciao

-

1

1

-

-

17 minutes ago, docc said:

My original (short) spacer has the two notches, but the new one does not. I suppose I can keep the collars and it will force me to get a proper bearing removal tool set. (Insert Waving Wrench Emoji here/ I am currently not privileged to use it, only the Bewildered Emoji

)

)

Grind or rat tail file some notches on one end of the new one docc so you can get a narrow ended drift on the inner race. Even with the collars you can usually get enough radial movement on the spacer to help get the drift on the inner race. After you install one of the bearings drop the spacer in and check how it levels up with the bore end face on the other side. Remember the bearing will have a little lateral play to take into consideration.

Ciao

-

1

1

-

-

3 minutes ago, docc said:

Yessir. You can see the 113mm spacer still has them (new) and my original 112mm spacer does not. It is fiddly to slip the axle through with the spacer loose, but very difficult to drift the bearings out with the spacer locked to the center.

I'd keep the the collars as you have found the spacer drops down and axle fitment is a pain. Some spacers have a notch ground on the face of one end so you can get a drift down the bore from the opposite end and get some purchase on the inner race for removal. I forget if the Guzzi has this or not but when I have them out I always grind another notch opposite the original if it has one or grind 2 notches for ease of bearing removal in the future.

My rear spacer had a collar standard. Some spacers only have 1 collar and you can then lever the spacer over a little on the non collar end and get a better purchase on the inner race for drifting as well.

Ciao

-

1

1

-

-

3 minutes ago, docc said:

So, keep the centering collars? They are important, perhaps?

The collars on the spacer?

Ciao

V11 Daytona project

in Technical Topics

Posted

Perish the thought

Ciao