-

Posts

342 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Events

Gallery

Community Map

Posts posted by Tinus89

-

-

12 hours ago, Weegie said:

If you know the original bulb wattage, I cannot be arsed looking it up, you can easily work out the filament resistance then just wire in a resistor in parallel of the same value and it should work as @Tinus89 has already stated.

No rocket science in the circuit, Ducati did the same thing back in the day, probably other Eye-Tal-yin producers.

Still freaks me out a near empty tank, full of fumes and an electric current passing through a thermistor in the space.

What could possibly go wrong, I mean TWA 800 was a fluke right?

The original bulb is 1.2W.

But I am failing to understand how this would work. Adding a resister similar to the 1.2W bulb would only "help" the fuel level sensor in not becoming too hot, right? Would it, in "full" position, still not allow sufficient current to flow through the high resistance in the fuel level sensor to light the LED bulb? -

On 2/22/2021 at 3:42 PM, Kiwi_Roy said:

The sensor is a thermistor, no capacitance at all just resistance that changes with temperature, yours read 1.4k because it was reasonably warm then you dipped it in fuel and cooled it down.

I just went through this again with a V7 owner, he took the regular speedo off snd wanted to use a 12 Volt LED in its place.

He tried using the LED directly with his sensor but of course found it was always lit.

I tried to talk him into using an incandescent like the VIIs use but he wasn't having it

Measuring the sensor on my V7 the thermistor is ~1,800 Ohms when cold (it will vary slightly depending on your fuel temperature) When the fuel drops below the sensor the V7 sensor starts to warm slowly until it's only around 90 Ohms.

You have to be really careful not to supply too much current as the sensor will just keep getting hotter and hotter until it fuses in a puff of smoke, the small lamp that the VII comes with is nicely balanced for the sensor, as the current goes up it lights and the current falls back. The V7 dash does a similar thing electronically, it limits the current to 75 milliamps.

I worked out that 150 Ohms was a good value to use in series with the sensor, it will pass enough current to warm it up but not enough to fuse it, the 12 Volt LED is wired in parallel with the resistor, it doesn't draw anything when the sensor is cold but is reasonably bright when the sensor warms up

On my V65 Scrambler, I changed all the bulbs (and the whole dash) for LED's. My tank came with a level sensor which I think (but will have to take those measurements) works the same way. This is the gauge: https://www.stein-dinse.com/en/nml-moto-guzzi-petcock-electrically-left-side-mille-gt-sp/item-2-1084757-23105370-.html

So obviously I discovered the light is always on. Reading your story, would installing a properly sized resistor in series with the fuel gauge be an option, with the LED parallel to the resistor? -

Lovely (potential) ladies and gentlemen. White smoke. The issue has been found!

Long story short, I have been changing components left/right so many times now, I lost the baseline. During this process, I had an intermittend spark, which in turn was intermittend again. I got frustrated, cursed, wanted to push the bike into a canal.Decided to start over. Begin at the base I was left off with (which was with the signal wires of the pickup crossed).

Put some fuel in her, had a huge backfire (remember the crossed wires?) But hey, the size of the backfire was new. Switched the wires back and BOOM. Started up "like a dream" But why?

And then there was it. I had already abused one lithium battery to failure. In the process of getting the fueling so that she would start quick, I jumpered the battery of my V11 onto her. I only used the engine ground (and not the central ground point cable I also engineered into it) and she ran fine (before the head gaskets).

The only thing that changed between the last no-run-with-fuel and yesterday's baseline attempt, was I added a central ground wire. I never looked into that because she ran fine without it earlier.

Started the bike, removed the ground cable and she died. Repeated 4 times without failure.

So yeah, the luck of the bike running without that main ground, turned into a big search later.The real story? I sold my Caponord 1000 two months ago to a friend.

Yesterday I received my Aprilia Tuareg 660 AND found out the above. Moral of the story? I just needed a new bike

Thanks everyone for thinking along!

-

3

3

-

2

2

-

-

My V11 pinged in the 4000-5500rpm range during warmer weather and WOT.

She is equipped with pod filters (PO did that, I like the sound so I keep them).

I solved the problem by (in steps) increasing the fueling using Guzzidiag and Tune ECU ( I thought that was the software, but could have been the Aprilia Caponord as well) in that area slightly.

-

2 hours ago, p6x said:

As reported in another thread, two weeks ago, I got a close call while being at College Station, about 100 miles from where I live.

The starter would not crank. As I was wearing earplugs, I was unable to properly identify the nature of the issue. The dashboard lights went dim, so current was sent, but it seemed the solenoid did not engage.

I put the bike in gear, and attempted a push start, which did not yield but moved the engine. Another starter attempt worked, and I got back home.

I tested the battery with my Motobatt tester and found nothing wrong with current charge level and amps delivery. I nevertheless ordered and replaced the battery with an encased Odyssey, allegedly rated for higher temperatures than the standard one. By the way, it fits the battery emplacement of the V11.

After installing the new battery, I could reproduce the no crank starter problem. Just once. A second attempt worked, and has worked since.

But the starter noise is not what it used to be. It is different. Something needs to be done.

Replacing a 20 years old starter may seem the best course of action. It is the only part of the starting circuit that has not been looked at. The easy way would be to purchase one of the MG Cycles replacement starter at USD 120.00 + shipping. But before I do that, I am willing to try a good clean up. That maybe sufficient. Note that MG Cycles has some limited replacement parts for starters, but they are all for older models.

Dismantle the starter and look inside. I am 99% sure you will see one or more loose magnets.

I had the EXACT same symptoms. Replaced the battery, no change. Until I disassembled the starter itself and found one magnet laying loose.

Roadside assistance helped me hook up a van battery (like a huge car battery), and the dead short in my starter pulled the van battery down to 7v!!After a few taps on the starter (which most likely relocated the magnet) she started up like nothing ever happened.

-

3

3

-

-

On 2/28/2024 at 1:15 AM, audiomick said:

Supposed to be 0,6 mm according to the workshop book.

Page 9 here:

https://guzzitek.org/gb/ma_us_uk/V35V50V65_041983_Atelier(GB).pdf

Is that what you had them set to?

Yes, it is.

I have been fiddling with the ignition for a while now. Somehow, the spark seems a bit weak now (not before) and the left side is not always sparking.

I am currently away from home for work, but when I get back, I will investigate further.

So far it seems like the problem is most present on the left cilinder.

When changing the ignition CDIs, coils (plus leads/caps) and even the pickup, the problem remains on the left side the most.

I will have to re-investigate the ignition parts & wiring from the start when I get back.-

3

3

-

-

13 hours ago, 80CX100 said:

You don't say how you verified the spark,but are you certain that it's actually sparking & at the right time?

(...)

While you're double checking all your grounds & contacts, verify the air gaps on any ignition sensors as well.

(...)

Time,patience & a fresh set of eyes always overcomes in the end.

As my flywheel mark is incorrect (due to orientation), I positioned the right cilinder at TDC compression stroke (so after the intake valve closes). I then marked the flywheel 7deg BEFORE TDC. The 7deg is based on the distance between the two marks (there are two for each TDC).

I then tried starting the bike whilst checking with a strobe light on the right cilinder. There was some scatter (starter motor working against compression) but the timing seemed correct.I also checked spark with the spark plug out & against the block, nice strong spark.

Believe me, time & patience have been in abundance (> 2 weeks already), so therefore I am asking on this forum for the fresh set of eyes now:)

11 hours ago, audiomick said:I've started thinking about the carburettors. Did you have them off completely when you changed the head gaskets? I could imagine it might be possible to take the heads off without removing the carburettors, but it would be more trouble than it is worth, I think.

So: the carburettors were most likely shaken up a bit, and maybe lay on the bench for a while on their sides or something. Maybe some gunk out of the float bowls found its way into a passage somewhere, or maybe the needle valves aren't closing properly anymore (because of gunk on the seat...).

Are you absolutely sure that the throttle cables and choke cables are correctly connected, have enough play in them, and operate correctly?

Incidentally, how do the seals on the choke pistons look? I can't see them causing your problem, but they get old and don't seal properly. I've even had one instance where the choke piston were out, and didn't seal properly when they went back in, even though the rubber disks that make the seal were not all that bad. Havin said that, when the chokes aren't sealing right you tend to have problems getting a stable idle rather than the bike not starting at all.

Going by your description, I'd more likely suspect the needle valves not sealing properly and therefore the carbs flooding, or something in that direction.

EDIT: don't forget to check the filter behind the banjo fitting that the fuel line is connected to. They clog up sometimes, but once again, I would expect bad running and not revving out properly more than not starting at all.

The carbs have stayed on the bike, I just loosened the rubber boot. They have been rebuilt with new parts 2 years ago & I have checked the jets are clear after the non-start issues. Throttle cables are OK & have free play. Choke pistons OK.

Also, I tried starting the bike with the choke float bowls empty (and fuel shut off) whilst spraying brake cleaner into the carbs, but even then she does not want to run. Therefore I don't really suspect the carbs anymore.

11 hours ago, motortouring said:My first suspicion would still go to the ignition. It sounds like the timing is incorrect.

Do jo have a stroboscope to check the spark while starting?

You probably wiggled the sparkplug cables when taking the heads off. Please recheck everything related to that, connection to the coils and caps and plugs.

For the carbs, is that PHF30? Or PHBH30?

Main jet is not important for starting. Only for full throttle. That is the last one to improve.

You could also share your question on the MGCN site, there are a few top experts on this.

To me it sounds like timing as well, but I can't explain what has changed when changing the head gaskets.

I have checked the timing with the strobe light as indicated earlier in this message.Carbs are PHBH30

-

On 2/23/2024 at 6:44 PM, gstallons said:

Have you gotten any closer to getting the bike running ?

Nope, no luck.

On 2/23/2024 at 11:50 PM, audiomick said:My opinion, based on my V35, which is basically the same in the pertinent points

First question: no. The timing sits on the end of the camshaft, assuming it still has the original contact breakers. In the first post, an electronic ignition was mentioned. Where does it get its timing from? Is it on the end of the camshaft? Does it still use the mechanical advance mechanism, and if so, is that clean and properly lubricated?

Second question: an electronic ignition was mentioned, so probably no points.

Third question: what sort of sensor does the ignition have? If it is a "Lichtschranke" (what the hell is that called in english?), i.e. a thing that works with a light beam that is interrupted by something to show the pulse, is the sensor clean?

So the classic point system has been replaced by Carmo electronic ignition. The mechanical advance is gone, there is an electronic pulse generator on the end of the camshaft like this one:

I do suppose this could have become contaminated, because the storage location of the bike is also used for other stuff (occasional spray paint, metalwork) so I could clean it up properly.

-

2

2

-

-

1 hour ago, audiomick said:

You did reset the valve clearances after changing the head gaskets?

I only ask because you didn't specifically refer to that.

Excellent question! Yes I did, and the adjumstment required was only minimal (set to 0.15 / 0.20mm). Updated the opening post as well.

-

Hi all,

I have a V65 Floriday which I converted to a scrambler. Different exhaust & pod filters. Yes, I know they are bad for performance.

My experience tuning carburetor bikes is very limited, so I may not have set her up correctly.After the rebuild, I stepped the main jet from 105 to 115. With adjusting the needle heights up (more fuel) the throttle response improved, so I went up in size to 128 an tried the same.

Again improvement, so I went up to the next size I had available (145). With the needles all the way down, the throttle response was perfect. Quick and without hesitation.

Tried starting her cold the next day, no issues.I then changed the head gaskets (both were the cheap version & wheeping) and since then, I cannot get her started anymore. I have not touched any of the wiring in the process.

The bike is equipped with Carmo Electronics electrical ignition and "wants to run" (plopping in the exhaust). Sometimes during starting the starter suddenly stops as if she tries to fire whilst on it's way up on the compression stroke.Checked/adjusted:

- Spark (good strong on both sides)

- Spark timing (created mark on flywheel as flywheel appears to not be installed in the correct orientation) for RHS TDC - +/- 7deg, checked with strobe OK

- Went back to jet size 128, 115 and eventually 105 (original)

- Changed spark plugs for new

- Compression both sides 13.5bar

- Switched spark plug leads left/right (no "trying to run" anymore when switched)

- Adjusted mixture screw anywhere between 1/2 turn and 4 turns (manual states 1,5 turns out)

- Adjusted idle screw up/down

- Emptied float bowls & tried to start her with brake cleaner, same result (only popping, no running)

- Removed air filters, no changeAfter AudioMick's response:

- Checked & adjusted (only minimal change required) valve clearance after head re-torqueing.Observations:

- When I remove the carburetors, there is some stagnant fuel in the inlet

- Sometimes the spark plugs are wet, sometimes not

- When I open the throttle or the choke, she "does not want to run", popping in the exhaust goes away like she gets too much fuel

- It is almost like the new headgaskets have changed something, or the ignition timing is off

- Sometimes she fires against the starter motor, so the starter stops briefly.

- Sometimes she fires in the inlet, but only a little bit (no loud bang or backfire)I am at a loss, so are some of my friends who have been trying to help me. What am I missing? Could the head gasket replacement have gone wrong?

-

About two months ago I gave her a service, including solving the wheep from the gearbox exit shaft seal.

Discovered the seal was not installed all the way, so instead of replacing it, I tapped it a bit deeper.Then the wheep turned into a leak.

So I went in again and disassembled the rear AGAIN, this time to replace the seal.

Oh well....-

3

3

-

1

1

-

-

So because of a huge house renovation, I have not had a lot of time to ride my Italian bikes

However, the previous car was increasing in maintenance (and a diesel, which was not the right choice anymore), so I wanted something else. And well, the Italian blood was already there, so I bought my 4th Italian vehicle, this time with 4 wheels.

-

13

13

-

-

"Sold the V11, bought a different bike".

Really? Well sort off...

I have always admired the look of the V11 with the higher mounted Titanium exhausts, and once came very close to buying a pair, however they were damaged and I liked the look of the original carbon-fiber ones on my Mandello Rosso better.

So when a member on here offered a set of carbon high-mount Gianelli's for sale, I went for it. He also threw a Stucchi crossover into the deal (thanks Crazyhorse!).

Mounted them last Tuesday. Oh my, what a sound! Not much louder, but a whole lot deeper.

But, did I imagine it revving much quicker between 3000 and 5000 rpm?Went for a ride. I'm not sure how much is to contribute to the Gianelli cans or to the Stucchi crossover, but WHAT a difference in mid-range pull! From 3000rpms onwards she just goes and goes. Like I bought a different bike.

-

13

13

-

-

Phil is correct, and I also noticed this. So I took a seal driver and drove the seal 3mm deeper into the gearbox case, causing the dust lip to now also remain on the sealbore on the shaft.

I did order a replacement seal, but will keep this on stock for now as it was more of a wheep than a leak. Thanks for all the comments!

-

4

4

-

-

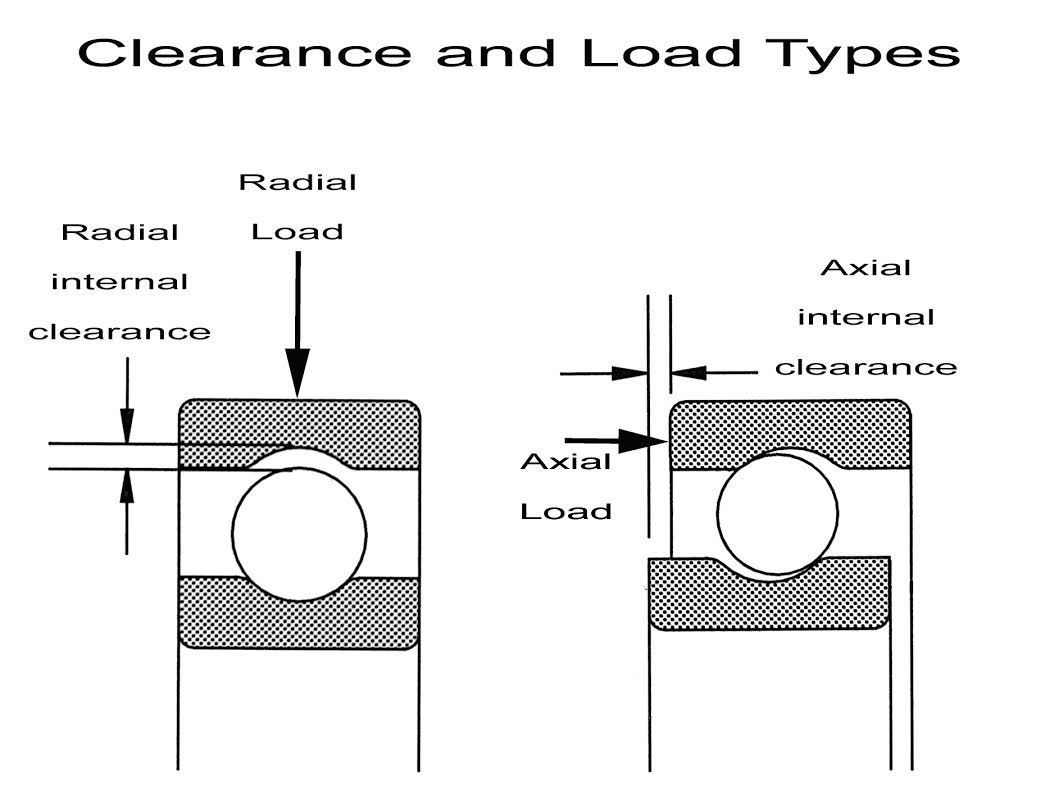

What I meant by that picture is explaining how I learned which direction is axial and lateral/radial

-

1

1

-

-

Thanks for the comments and comforting!

Just for the record, I have always learned it like this (at Mech. Engineering uni):

-

2

2

-

-

Hi all,

During maintenance (greasing the driveshaft), I discovered the driveshaft was pushed over the normal mounting position on the gearbox output splines. Most likely hydraulic lock or sticking (due to barely no driving in the last two years, house renovation) has pushed the driveshaft further onto the splines.

I also noticed my output shaft seal to be leaking a little (but it can also not have been installed deep enough, but I did not have a tool at hand to drive it any deeper), but also discovered my output shaft to have approx 2-3mm axial play. There is no lateral/radial play and also no notchyness in the bearing.

Here is a video: https://www.youtube.com/shorts/74sLrz0mv6A

Anyone who can tell me whether this is too much play?

And if it is, can I replace that bearing with the gearbox on the bike or will it have to come off?

-

15 hours ago, audiomick said:

Turns out the battery may not have been flat. I can't say for sure.

I went in today, got the battery out and re-installed it. As I was about to try and start it, I noticed the contact plate of the ignition switch hanging out of the left side of the fairing. I don't know if the bike was tampered with before I tried to start it last night, or during the night after I took the battery out and put it on the charger in the store room.

Anyway, I found the bit with the spring loaded copper contacts on it lying inside the fairing. With the help of a copious amount of electricians tape, I was able to make a contact, start the bike, and ride it to my garage. It is in there now, and I hope to be able to get it fixed fairly soon. First thing is to have a good look at the damage, then do some research into what parts and if they are available. As far as I could tell by squinting in under the instruments, the plastic cylinder that the whole business lives in is broken. I was too dispirited to have a closer look after I got it into the garage. Needless to say, I am not amused.

Edit: the first results of an internet search are not very encouraging....

This very much sounds like it has been tampered with...

-

If the lights dim and you do hear a "click", then there could also be a loose magnet in the starter motor. I had that, and all symtoms showed a poor battery (voltage went down significantly when I pushed the button, as low as 6v).

After replacing the battery, the problem persisted. I fixed it by changing out the starter motor & disassembled the old one, found a loose magnet inside.

-

2

2

-

-

Thanks docc, that explains why I could not get my head around that!

-

1

1

-

-

Do you have a picture of the CBR600RR mirrors on a sporty?

Which model year CBR are they from?

I am very unsatisfied with the original mirrors, and even less satisfied with the current aftermarket replacement I have. -

On 12/14/2022 at 2:54 AM, docc said:

If the risk of the aluminum flywheel that is coupled to the "single plate clutch" is fair discussion. Has any Rosso Mandello suffered a flywheel failure?

Perhaps our member @Tinus89 could contribute . . .

I have not heard of any RM's (or anything else than a Scura, to be honest) suffering from the spontanious decomposing flywheels...

-

4

4

-

1

1

-

-

Right. Spending about 70EUR for a small peace of steel is a bit steep.

Spending about 70EUR for a shifting improvement of my V11 isn't.

Sign me up please:)

-

2

2

-

3

3

-

-

What would be the price including postage to The Netherlands?

Fuel Level Switch

in Technical Topics

Posted

I am no electrics guy, so I may not understand, but what I meant is essentially what GuzziMoto wrote:

I think that an added resistor (instead of the bulb) will protect the thermistor and therefore safeguard the intrinsically safe system in the tank, but I think even with the high resistance of thermistor & resistor, the current flowing is still enough to light the LED. As the LED lights with the thermistor cold (and ~ 1800ohm - I have not measured yet), it will most likely also light with the 1800+150ohm resistance...

However, would switching the LED through a 100mA relay not work? Something like this (https://www.diverseelectronics.com/upload/documents/SARA.pdf), which can only close at ~100mA (which almost lights the incandescent bulb). I would suppose the coil in the relay would still allow some current to flow for the thermistor to heat up & keep it's function.

Also, are we confident this fuel gauge works with a thermistor as well? Because it has a small "float" as can be seen on the picture:

Keeping the stock bulb is not an option. I have a set of LEDs nicely built into the handlebar clamp, the incandescent bulb simply does not fit there. Making an electronic solution is less work than going back to the original bulb...