audiomick

Members-

Posts

2,993 -

Joined

-

Last visited

-

Days Won

62

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by audiomick

-

Yes, just like that.

-

Now that we are all grown up and have become responsible, we know that this is not really true, don't we (Dorothy...)? But I used to be pretty good at this when I had one of those bikes

-

Yeah, looks to be the same principle. Look here on the second half of the page under "product specifications": https://www.stahlbus.de/lng/en/bleeding-system/bleeder-valve/conical-sealing-standardtype/stahlbus-bleeder-valve-m6x10x135mm-steel-1335.html The mechanic I go to when needs must be uses a bit of hose with an inline one-way valve in it. No idea where he got the valve from, but with that he effectively has the same principle as the speed bleeder / stahlbus system in a version that he can stick on whatever bike he is currently working on. I've watched him using it, and it seems to work very well.

-

-

-

-

good burnouts are important.

-

Who makes them? Are they like these? https://www.stahlbus.de/lng/en/bleeding-system/bleeder-valve/?language=en

-

I'm sure you can. It wouldn't stay there long, though. Those tiny little molecules are accomplished escape artists.

-

That is what I was expecting, i.e. I expected to see grease come out of the join between the two parts of the shaft as an indication that there was enough grease in there. From my very reliable source I have been informed that (a) normally, excess grease does indeed come out past the O-ring, and (b) when one is greasing the spline with a grease gun and grease comes out of the join, that is already too much. According to my source, one or two pumps of the grease gun is enough. When I think about it, he's right. There is not much space in there. During the course of my experimentation, I pumped some grease into the dismantled end of the other shaft that I have. Two pumps put in enough to, I reckon, more than fill the available space. It might even be one of those fabled "less is more" situations.

-

That's done. I was pleased to discover, after having seen some unsettling pictures here, that that bolt on mine looks good as new, and was well greased as if someone had at some point actually done some maintainance on the bike. As far as the pivots on the shock go, as mentioned, I'll be getting another go at them.

-

Thanks for the tip.

-

I've been thinking about that. Would it be really tragic if that end of the shaft wasn't air-tight? Phil wrote that the bung in the end is just a plate staked into place. I dare say that isn't really air-tight even when it is new. I'll be taking mine out again to have a close look at it, but I'm inclined to think that if I don't rely on the grease nipple to lubricate, i.e. take it off every year or two and grease it dismantled on the bench, then it shouldn't really matter too much if that bung doesn't seal 100%. Or am I overlooking something?

-

The name has been around for a while... https://en.wikipedia.org/wiki/Shooting_brake

-

I think I've answered my question: I found a photo in the workshop manual, page 49 here: https://guzzitek.org/gb/ma_us_uk/1100/V11_1999-2003_Atelier(Compil-GB-D-NL).pdf Looks like I'll be taking it out and turning it around...

-

I had the shock out to be serviced, and now am usure which way around it was mounted. It seemed to me that the shaft end with the aluminium eye wouldn't fit in the mounting position in the swing arm, and the hose to the reservoir lies fairly well with the shock mounted the way it is now, so this is how it went in. Is this the "right" way around? Das it actually matter which way round the shock is mounted?

-

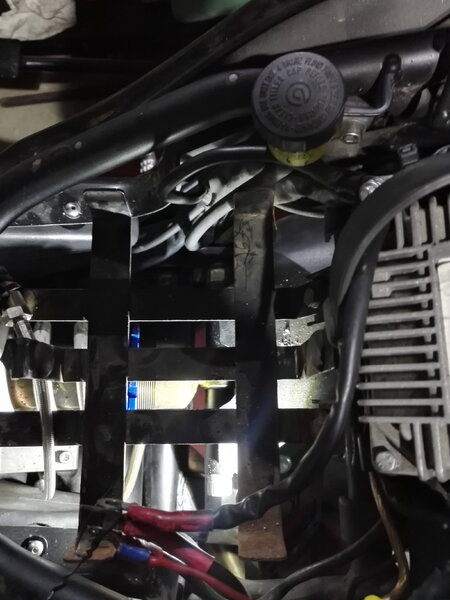

From the album: audiomick

-

From the album: audiomick

-

From the album: audiomick

-

So, on the Griso, the bleeder is not secured in such a way that one can use it one-handed? Intersting. I assumed it would be.

-

No, they aren't. Neither on my V11 switch nor on the scooter switch. I did take a photo of the wiring side of the switch plate, but seem to have lost it. Edit: wait, here is one I already had in the gallery

-

Very good question, docc. I went looking for such a hole on the shaft in the picture, and couldn't find it. EDIT: I might add that I have a vague memory of having noticed in my childhood just such a relief hole on the drive shafts of various mowers, hay balers and what have you that were designed to be driven from the PTO shaft on the back of a tractor. Watching my father grease those was where I learned how to use a grease gun...

-

Yes, it does. I cleaned out the shaft before I installed it, and only put a very thin layer of grease on the spline. There are enough warnings here about how hard it can be to re-assemble the shaft if one puts too much grease in there that I was cautious, and was relying on the grease nipple for the proper greasing. The grease that came out in the yoke is all fresh.

-

There's a thought. On the "against" side, that sort of wear would presumably only turn up when the "park" lights had been used very frequently, such that the step from "lock" to "park" has seen a lot of use. I almost never turn on the park lights, but maybe other people do. Edit: or maybe the switch is just generally worn out, and the detents are not that precise anymore. :scratching_his_head_and_thinking_emoji_that_we_desperately_need_here.

-

Thanks Marty. I thought as much, and went looking for such a hole on the shaft in the photo I posted, but couldn't find it. Nevertheless, what you write makes sense. I guess I'll have to go and have another look... EDIT: and what docc wrote. I've read all over the place that pulling the shaft apart can be difficult because of a vacuum lock, and putting it back together with too much grease on it difficult for the opposite reason.