BrianG

Members-

Posts

743 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by BrianG

-

You guys really gotta quit smoking that stuff! The bottom line to the PC III tuning effort was to get something like decent gas milage, by losing the over rich section, and to get rid of the flat spot in the WOT accelleration mode.

-

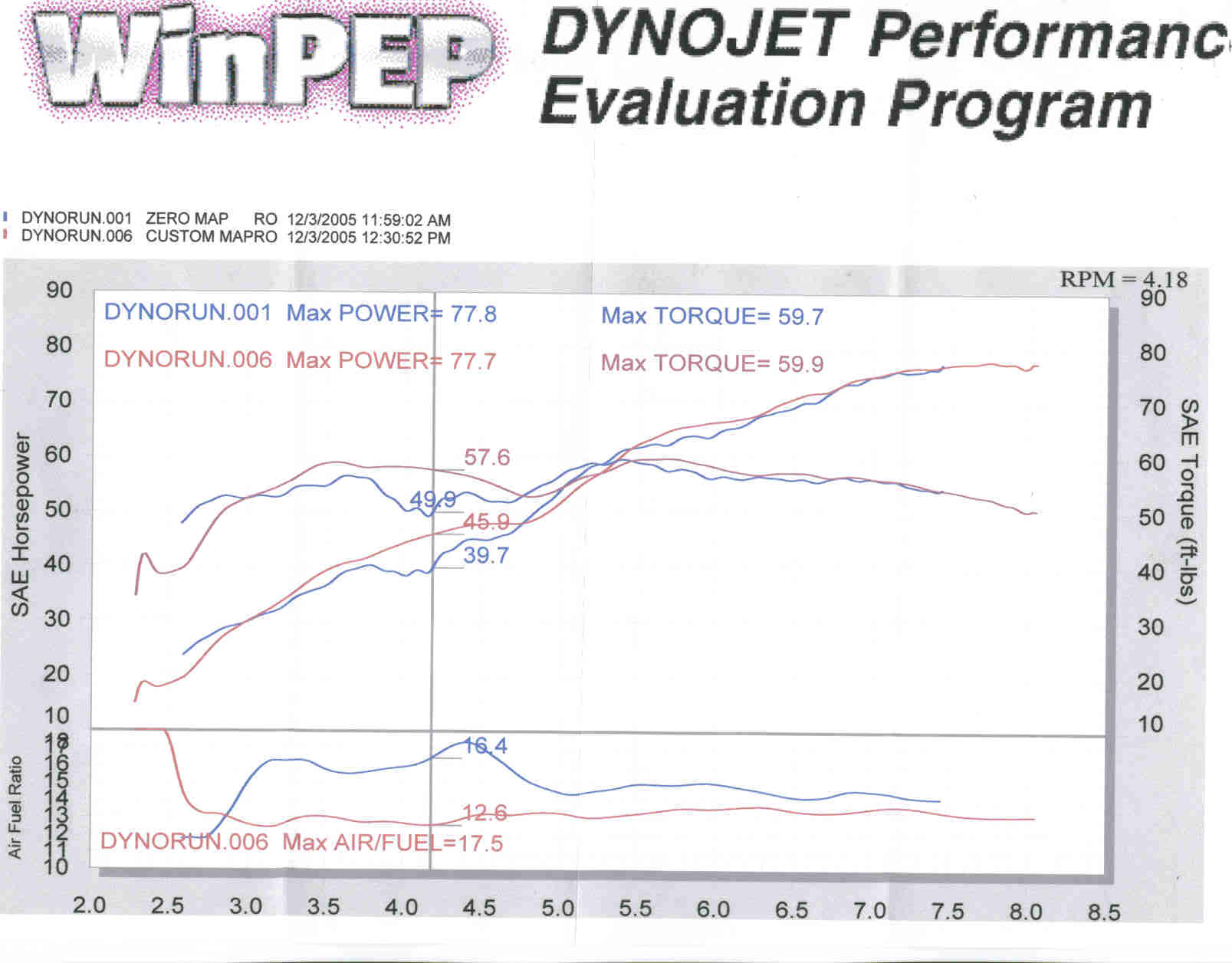

Wow...... my bad!! I'm not sure how I figured that 17+:1 was rich!! Anyway, I found the graphs of the pulls I did in the spring of this year where we did manual laptop re-mapping on the first PC III. You will note the difference in torque range numbers as compared to the Dynojet dyno readings. I'm not sure whether this is a function of the weather (it was +80F and about 10% relative humidity), or the dyno used. The first pull is without the PC III, and you can see how the A/F mixture fell right off of the LEAN end of the scale. Although the HP and torque curves are actually less smooth in the final pull, you can see the much flatter Air/Fuel curve. I wasn't very happy with this method of tuning because of the weird curves, but drivability was notably better than before the PC III. I watched as this dyno did about 20 more motorcycles, most of whom were only there to see their HP numbers. I was amazed to see how flat their A/F curve was, and how smooth their HP and torque curves were. My son says I need a 'busa!! ...... 'course he rides a Fireblade!

-

Here is the result of the install of my second PC III. The worse (blue) track is the raw PC III map that came in the unit as the "Custom Map" for the 2000 V-11 Sport with Mistral's, K&N and drilled air box. Unfortunately, we didn't do a pull on only the stock ECM, without the PC III. That might have been interesting to compare. You will note that there was no huge gain in HP or torque, but it flattened the A/F curve nicely. which should result in notably better milage becasue the curve was WAY rich above even best-power. You will also note that the original PC III map had none of the classic lean-spot that the original V-11 map is noted for... This is the second PC III because the first one died for no apparent reason while I was cruising down the road.

-

It is not a unilateral brake pad issue. Single front-disc motorcycles do not veer when the brake is applied. It is not a steering damper issue. The damper only slows the normal fork responses to chassis forces, it does not actually change them. There are only 2 possibilities for this issue: 1) uneven weight distribution.......... unlikely unless your butt is asymetrical 2) wheel alignment: The front wheel primarily tracks according to chassis input or control input, rather than controlling the track..... set yourself up on a straight line on a "normal" bike and let go of the handle bars... the bike tracks straight. Then shift your weight sideways on the seat or lean sideways.... watch the handle bars as the front wheel changes track. Because of the rake and trail of the fork geometry a twist in the fork will aim the center line of the rake/trail plane away from parallel with the plane of travel of the wheel, imparting some lateral tracking. To check fork alignment, use horzontal beams across the triple clamps and a T-bar across the front wheel. Obviously, the 3 axes have to be parallel. The rear wheel is the most common cause of alignment imbalance on motorcycles with chain drives, since it is quite easy to set the rear axle askew when adjusting the drive chain tightness. Being new to the Guzzi world, I am not sure how easy it would be to set the rear axle off line. Obviously this would be a less likely issue on the Guzzi since owners are not frequently messing with the rear axle, but I wonder if it's an assembly possibility. Aligning the rear axle requires a length of string or cord. These days of different front/rear tire width requires some fiddling that wasn't necessary back in the day. The idea is to use the string to carry a straight line longitudinally across two (well separated) points on each tire. The front tire determines the trajectory of the line projected rearward. If the rear wheel is cocked from the straight forward position, there will be a gap between the tire and the string at one of the 2 expected contact points on the rear tire. The trick with different front/rear tire sizes is that you have to "shim" the front tire side wall out to the same width as the rear. That's actually quite easy, by measuring the rear tire width and using a wood plank of appropriate thickness fastened to the front wheel. Wheel alignment isn't the trivial consideration on a motorcycle, that a lot of people think it is.

-

The narrower tire will certainly quicken the turn-in, as will the slight decrease in steering head angle and trail that result from the smaller diameter. As long as the manufacturer spec's that tire for your 3.5" rim and you like the increased manouverability/decreased stability it's just a personal call.

-

Having lived in Canada all my life......... I'd suggest that it's a bad idea unless you at least thin the oil, or warm it somehow. Even a 100W bulb (trouble light) placed close to the oil pan, for an hour, will substantially heat the oil. Up north, we used to add (about 5% of the oil volume) gasoline to the oil of the aircooled aircraft engines to thin the oil before starting them if they had sat long enough to cold-soak. Better to drop that oil and run 5W-30 if you are going to operate it in those temps.

-

Somebody on here did a decent job of crafting the Penske unit to the V-11S

-

I'm in if there can be some accommodation for a shorter lever-arm option.

-

Started this adventure with a '68 Honda 125 twin at 14 yrs of age. Moved to a Norton Commando 750 at 17 yrs. Kept that through university and early career days. Kids came and we went to dirt-bikes to get them into the sport. I made my way from IT 200 to WR250 to CR500... loved the WR! When the kids hit licensing age I found a VFR 750 while the boy started with a RZ350, then RZ500. I needed something better to keep up, and the RZ 500 was a pain to keep tuned so we got twin CBR 900RR's while the daughter inherited the RZ 350. After a couple of years she moved to a Honda VTR 996. The kids graduated from high school and moved abroad. The son took his 900RR to the Air Force and the daughter sold her VTR to get to the French Alps. With them gone I decided I was done with motorcycles and sold my 900RR. That lasted about 3 months...... I got the shakes seeing no motorcycle in the garage so I found the V-11 Sport on e-bay. It's all good again, and I have something to ride when the boy comes home.... unless he brings the jet!

-

Aside from the safety issue of inadvertently grounding the + terminal to ground through a tool........ it makes NO difference which terminal you connect/disconnect first. If you hook up a plug for this it is absolutley safe to use a plug with both (2) connectors in it........ just place the plug away from the battery so that if you inadvertently disconnect the plug with the charger "on", the spark will not ignite the hydrogen released from the battery in the charging process.

-

VERY nice..... too bad it won't fit in a spine-frame!

-

This is precisely the reason that platinum and iridium are used in the construction of spark plugs for new vehicles. These metals resist the ion exchange of spark generation far better than the original material used in spark plug construction. This is only significant if the spark plug change interval is extended. The heat range of a spark plug is determined by measure, and not by prediction, so a XXX6XX plug is going to run in the "6" heat range regardless of it's construction type.

-

It's the Norden engine that was used to power the proto-type V-11 Sport during chassis testing of the Marzocchi vs Ohlins fork trials.

-

Oh picky, picky!! Next you'll want the shifter on the right side of the bike, with first gear "up" and the rest "down"............................. (like it should be!!)

-

Well, thanks for the reference! I am always pleased to become more informed about these issues by the assistance of friends on this forum. Again, this proves to be one of the best forums on the web!

-

Ernst, I think that this is incorrect............ The lambda sensor is an oxygen sensor. When hot (at least 250 degrees c.), the zirconium dioxide element in the sensor's tip produces a voltage that varies according to the amount of oxygen in the exhaust compared to the ambient oxygen level in the outside air. The greater the difference, the higher the sensor's output voltage. CO does not figure into this reaction.

-

Replace them with LED's!!

-

Tape a few 1' long pieces of yarn to the top edge of your windscreen and you can see the flow pattern. If you trim off the windscreen, a bit at a time, or open up a vent in the lower edge, you will be able to actually see the differences made. There is a maximum functional length for this technique, which depends on the turbulence generated. At some point the yarn will just get whipped about. You can play around with various lengths, but it's an interesting exercise.

-

Now THIS is the set of pipes I want for my V-11 Sport!! Anybody got an idea of who could do that?

-

The issue to consider is that the suspension's cycle is, in fact, one 2-sided event. The spring provides the operating "force" on onside, while gravity provides the counter-force on the other. The (more significant) initial motion is the compression event, when you hit a bump. If this force is substantially absorbed by the spring but not damped, the motorcycle receives no upward accelleration that has to be dealt with in terms of handling (nor felt by the rider). The second half of the cycle (rebound) is responsible for the dissipation of the compressive energy the spring absorbed, hence the much greater damping value on this side of the cycle. The damping cycle is a little less than optimal in order to prevent the fork from "pumping up", which is the accumulated travel that would occur if the stroke were not allowed to complete before the next bump. This results in some over-shoot of the fork tube past the neutral point and the second half of the cycle ensues, to damp the remaining energy. With NO compression damping the fork would compress again past the neutral point, and it would take another cycle (or more) to damp the force of the bump. With a bit of comperssion damping it can be finished in one cycle. This is desirable because a completed cycle contributes nothing extra to the suspension's reaction to the next bump. This generally becomes significant in near-limit traction situations, on rough surfaces. That is to say, it's only really a noticable issue when racing on a rough track. Optimal track setting for springing results in near-full-fork-travel when the rider brakes as hard as he can. Optimal compression damping is indicated when the rider bounces his weight on the properly sprung fork, and the fork overshoots to an "above-neutral" position on rebound , and then settles quickly on compression, just to neutral , with no need for the initiation of a second rebound cycle. Typically you will find the right springing first, by measuring unloaded and loaded sag values. Then you will set the compression damping to zero and ride the track to determine proper rebound damping for the rough bits, trying to set a little as is reasonable. Then you will set the compression damping to what is needed to kill the second rebound cycle, as mentioned above. Street bikes need not be damped this closely, and in fact will feel plusher with a bit of a second damping cycle. Which is good if you like the ride of a Harley or a Lincoln...... but not so good if you like the ride of a Sport Bike or Sports Car.

-

Sorry Rocket man, but that's not correct. In fork damping, compliance depends far more on rebound damping than compression damping. Inevitably, when you see only one being adjustable, it is rebound.... with fixed compression... which is actually fixed VERY soft.

-

It's not that Traxxion Dynamics is bad, it's more like I'm curious, and spinning wrneches in the garage is cheaper than spending time in the bar....... It's not, really, but I have my wife convinced! I'm just curious to discover what the forks will feel like with optimized damping and progressive-rate springs. Either that or I'll have to break down and screw that supercharge to my car... and I'm still a bit scared of that project!

-

Ok...... I forgot that the airspace is measured at full compression!

-

With only 100mm of airspace don't you run out of travel a bit shy of 100mm of travel? ratchethack...... are you now running the Wilbers .7 - 1.0 kg/mm springs? I'm thinking that maybe I'd give the progressives a go, and swap them this winter. What spacer length did you settle on?

-

You will find that 1.05 or 1.10kg springs are right for you. I'm 225 lb and love mu 1.05's..... but I do like a cushier ride. Cartrgdge forks all service more or less the same. I doubt that you'll find much difference in the Marz and Ohlins fork service process. Spring manufacturer is no biggie. Just get a good quality spring. Traxxion did my Marz forks but couldn't alter the valving and didn't like the stock units, so the replaced them with Max's new units. I'm in love! He can certainly optimize the Ohlins units.