-

Posts

935 -

Joined

-

Last visited

-

Days Won

42

Content Type

Profiles

Forums

Events

Gallery

Community Map

Posts posted by MartyNZ

-

-

A tantalizing presentation. Lots of interesting suggestions but little helpful information. What coatings are good? What is that "better oil"? The only takeaway I got was "ZDDP (zinc additive in oil) increases friction but decreases wear", which suggests that more is not better.

-

2

2

-

-

I have Penrite Pro Gear 75W-90 in my gearbox. No oil mist.

The troublesome vent hose can split at the outlet on top of the bell housing, which lets oil vapor into the clutch area. When I bought my bike, it came with an oil drip at the witness hole at the bottom of the bell housing. Replacing the vent hose fixed the leak, but I couldn't see the cracks in the hose until I took it out.

I have a part used bottle of Shockproof Heavy with about 750ml still in it, not quite enough for a gearbox. I bought it from Brake n Transmissions BNT

-

2

2

-

-

Is the vibration felt in the bars or foot pegs? How long since the cylinders were synchronized?

-

4

4

-

-

57 minutes ago, Yam350 said:

should there be any movement on the bevel box?

No.

It sounds like a spacer is missing. Maybe the short one that drops out when you remove the back wheel.

Or possibly a collapsed needle roller bearing in the RH outboard side of the bevel box. The inner race of that bearing is also one of the several spacers along the axle.

-

2

2

-

-

If it claims to fit the square head then it should be fine.

Before you buy, have you seen Joe Kenny's stuff?

https://www.ebay.com/usr/jjkpguzzi?_trksid=p2057872.m2748.l2754

https://www.ebay.com/itm/354611407158?hash=item52907ca936:g:IBgAAOSwWopjBW0A

-

3

3

-

1

1

-

-

If you have the time and skills, here's a design using 2 hall effect sensors and neutral SW inputs.

https://www.electronics-lab.com/project/motorcycle-universal-gear-indicator/

Of course it can't figure out any missed shifts and false neutrals, so you may find it showing 7th gear

-

3

3

-

1

1

-

-

14 hours ago, Janusz said:

And still you do not know what gear you are in...

True, fair point.

I have tried to shift up from 6th a few times on the open road, but it takes about the same time to attempt the shift as to glance down at a shift indicator, so I don't think I need it there.

I have also found myself trying to select neutral by shifting up from 2nd instead of 1st, so an indicator could be handy there.

The aftermarket shift indicators I've seen would look clumsy on my bike, so I'm prepared to go without.

-

3

3

-

-

16 hours ago, LaGrasta said:

... I was doing 130mph! ...

@Scud has a photo of his speedo showing 183mph. (Sort of)

-

2

2

-

-

I just use the tacho or engine sound. Above 7000 change up. Below 3000 change down.

-

3

3

-

2

2

-

-

It's a good time to repaint the tube and clamping block while it is apart, to repair the road grit damage caused by that inadequate front guard.

-

-

-

6 hours ago, mikev said:

I am missing the front and rear main airbox bolts to the frame, one looks like it needs to be ~3.5" long (front) and rear ~2-2.5" long. There are three bolts for each side panel, some holes are different sizes. I have some oddballs in there that sort of fit.

On the front left of air box there is a brass nipple for a hose connection. Can I ignore and seal this? Or reattach with new hose to wherever its supposed to go. Which is where? On the front right of air box there is a small rectangular hole flanked by screw holes on either side which I assume is for some sensor. I'll probably just cover this unless there is a good reason to find a replacement. Both holes would let air into box after the filter.

I see two screws in red frame under tank / seat junction which I do not think are involved in this airbox but wonder what they are for. Can send pic if helpful.

Same question for the two screws on the rear of airbox facing toward battery. What are they supposed to attach to?

The boots closest to engine on both sides look a bit cracked. And should probably be replaced.

My airbox is off at the moment, so I took a look.

The hex head bolts holding the airbox lid down are 6mm dia x1mm pitch, length 82 & 30mm from under head to end.

The screws attaching the side panels to the airbox are button head chrome or SS 5 x 0.8mm 12 mm length.

The brass nipple is for the engine breather hose from the banjo at the top of the spine. Any oil resistant low pressure hose will keep oil vapour from making a mess.

There should be an air temperature sensor on the front of the airbox. If it's not there, the ECU will assume a default temp, and the engine will be out of tune if the air temperature is not 20°C.

The 2 screws on the rear of the airbox attach angle brackets going to frame mounts. You need those.

The engine is sensitive to air leaks, so replace the cracked intake boots.

The designer took some trouble to optimise the intake system, and you are restoring to that. Expect the engine to run better over the rev range, and with proper air filtration, when you finish.

-

4

4

-

3

3

-

-

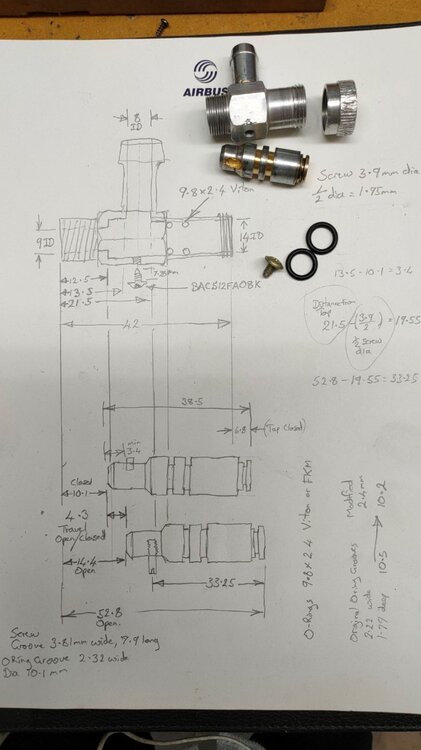

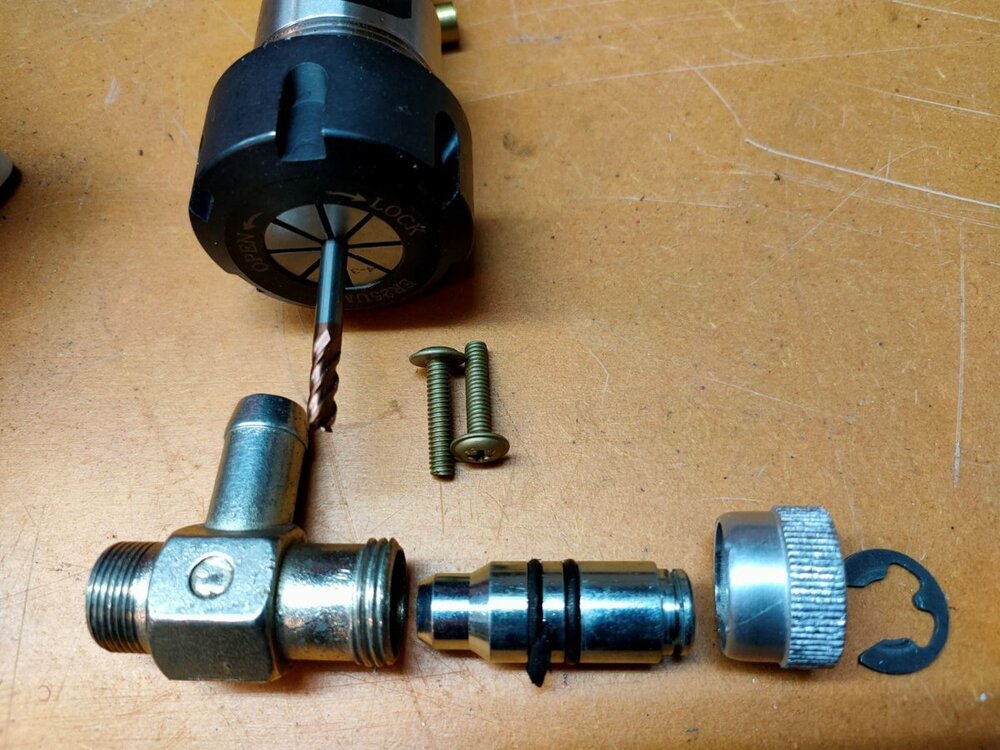

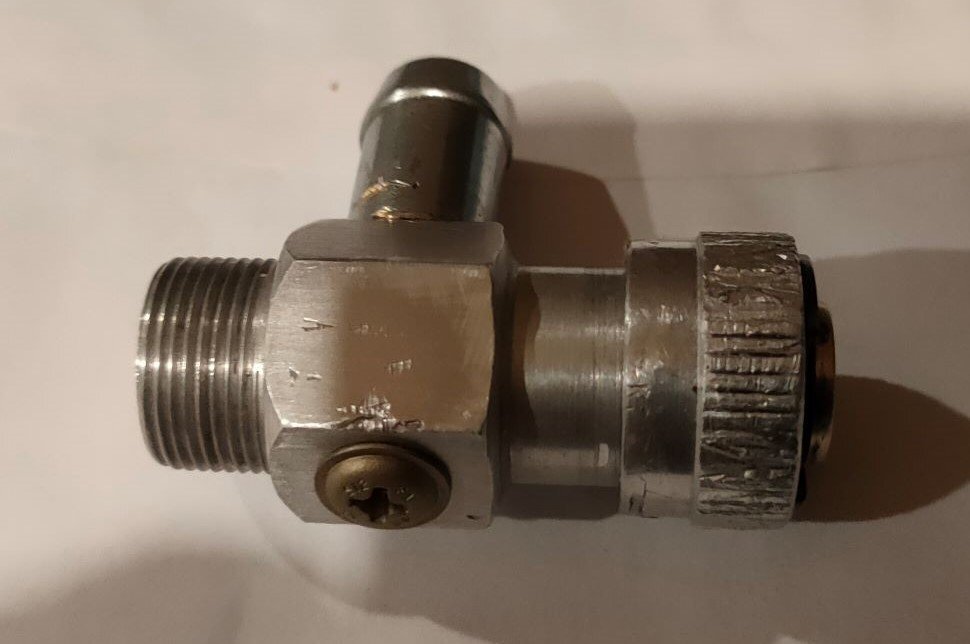

I followed @Lucky Phil's experience and advice and fixed 1 leaking tap. 2 more to go.

Steps are: enlarge the O-ring grooves, machine an anti-rotation slot in the plunger, adapt screw to make an anti-rotation pin, tap a hole to the valve body, fit bronze anti-friction washers on each side of the knob, put sealant under the anti-rotation pin, assemble with fuel resistant grease.

@cash1000 tells me that his modified tap is easy to open/close, and it doesn't leak.

-

4

4

-

3

3

-

-

-

Have you read all the posts on this site that use the words "Startus Interuptus"?

-

3

3

-

-

Relays front to back:

1. START (5 Pin Relay)

2. LIGHTS (4 Pin Relay. 5 Pin OK)

3. NEUTRAL/SIDESTAND (4 Pin Relay. 5 Pin OK)

4. ECU (4 Pin Relay. 5 Pin OK)

5. FUEL/COIL/INJECTION (4 Pin Relay. 5 Pin OK)

-

2

2

-

-

40 minutes ago, cowtownchemist said:

Is it recommended to re-map the ECU with the Meinolf map no matter what? Or do the re-map only if a performance improvement seems necessary?

You can save your original BIN file off the ECU using the reader. Saving takes about 15 minutes. Then you can load the Meinolf BIN. Loading takes about 10 seconds. Ride and decide yeah/no. Revert by loading the original BIN, or keep, it's a no-risk choice.

-

1

1

-

2

2

-

-

On 5/25/2023 at 2:41 AM, PJPR01 said:

... be careful getting DeOxit on the soft rubber seals ... as the chemicals cause the rubber to swell...

I wonder if washing the seal in hot water and detergent, then drying for a day or two, would let it shrink back to normal.

-

1

1

-

-

19 minutes ago, LowRyter said:

SO, use dielectric grease on the contacts?

If you mean the ignition switch, then dielectric grease would work, but it is best used in static connections to keep water and oxygen out.

I have had good results doing general cleaning/lubrication of switchgear using automotive electrical switch grease: Lubriplate DS-ES, but any white lithium grease is good.

https://www.lubriplate.com/Products/Grease/Multi-Purpose-Greases/DS-ES/DS-ES/DS-ES,-1-75-OZ-TUBE/

I use dielectric grease on all exposed electrical connections. It is particularly good on ignition coil connections, but I have heard that it is bad in vented relays, where it can mess with contact resistance when contact sparking happens.

-

2

2

-

-

20 hours ago, docc said:

I tried an idea on my V11 to both reduce any chance of water ingress and reduce unsprung weight. An alloy vent plug with an oil trap, and a short hose with a foam filter. No oil leaks or water, but then there wasn't any before I started either.

-

6

6

-

-

-

The relay bases have dovetail grooves to link each base to the next. You should be able to hook the bases together to align them by sliding vertically. Then you need another mount bolt as shown by P6x.

-

2

2

-

-

6 hours ago, docc said:

Seriously, other than Relays, Battery, and Tune-up: the three most neglected areas on V11:

> Rear drive: far right side needle cage.

> Sidestand fasteners, both, but especially the high torque large bolt.

> Charging system failure (ungrounded regulator, melting 30 amp fuse, broken stator wires).

Also the parts that might look ok now, but should at least be in your bin of "parts that I may need soon":

> Crankcase Vent hose from bell housing to the top of the spine

> Hose couplings between the throttle bodies & the intake spigots

> TPS Sensor

> Phase/Crank position sensor

> Oil pressure Switch

> The improved gearbox shifter return spring

-

4

4

-

2

2

-

Signal indicators

in Technical Topics

Posted

When I fitted LED indicator lamps, I needed an electronic flasher, since the current draw was too low to make the original flasher work. Then I found that the indicators on both sides flashed at the same time. Evidently the dash indicator light was providing a ground return through the other side lamps. I had to rewire the dash light as shown in the pics.

EDIT: The final version has 18,000 mcd (millicandela) LEDs with 360Ω resistors.