-

Posts

5,449 -

Joined

-

Last visited

-

Days Won

276

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Lucky Phil

-

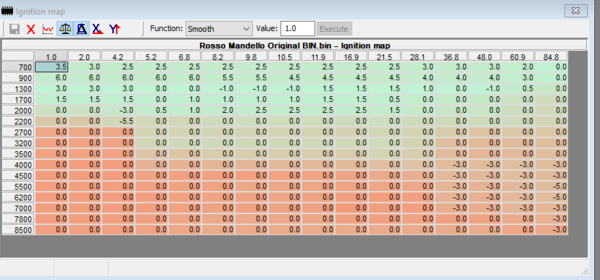

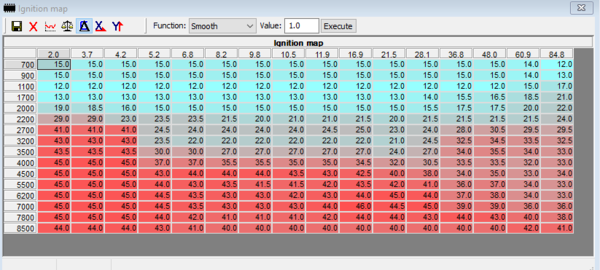

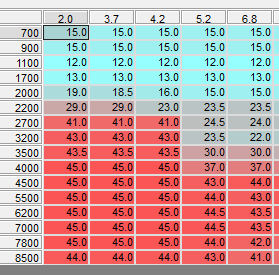

The engine obviously has issues around this rpm/Throttle angle which is probably a combination of combustion chamber shape and burn speed, intake tract length, cam timing, header size and collector design. A "problem area". I don't know whether the hiccup is the engine missing an ignition ( skipping a beat for fuelling and ignition interplay) event OR it is "loading up" and coughing back into the inlet either because of a really slow fuel burn due to the much reduced advance that has the combustion still happening when the inlet valve opens again on the overlap. From my memory of my original engine it feels like the latter, a small cough back into the inlet on 1 cylinder. Adjusting the fuel could well mitigate it to a certain extent as might changes in engine and OAT. Just random thoughts but I'd be interested to see what effect an ignition advance change has. The Daytona engine FWIW has totally different mapping in that area which is to be expected I suppose. Ciao

-

Yea maybe. The OP should measure the ID and OD and see what the interference is. If it's 2mm or something that's a compatibility issue but .2mm is just production tolerances. Ciao

-

You might need to "fettle" them or the header weld a little. It's the difference between "fitting" and "mechanicing" Ciao

-

I "think" you can use a 15RC in a 15M but not the other way around. The 15M and 15RC use a different XDF file although the same reader/writer. Ciao

-

Here you go docc

-

From the album: lucky phils V11

-

From the album: lucky phils V11

-

From the album: lucky phils V11

-

Moto Guzzi V100 Sport Tourer: water cooled, 120 HP (26th of August 2021)

Lucky Phil replied to p6x's topic in Newer models

Oops forgot the link. Ciao -

Not as physically hard as the sideflow ones which are Bitch. I was assuming he already had it substantially apart. Ciao

-

Any local car efi tuner/maintenance shop should be able to do them. They are a common injector to lots of cars. Ciao

-

Ok cool docc. Remember I was looking at the huge change in ignition timing at the hiccup point a little while back and postulating on that as well. Did anyone adjust/play with that in Tunerpro and see if that had an affect? Ciao

-

I'll have a refresh with the information you've provided, thanks. I was just recently reading/skimming a Lithium battery thread on a German forum and was noting the compatibility or otherwise of LI batteries with some motorcycle charging systems and this battery interested me in that it includes it's own controller which I think most quality ones do but it looked like it was designed to accommodate a wider variety of chargers and charging systems. Ciao

-

Moto Guzzi V100 Sport Tourer: water cooled, 120 HP (26th of August 2021)

Lucky Phil replied to p6x's topic in Newer models

This has some nice detailed images. Turn the sound down as the "Guesstimator" doing the commentary has nothing useful to add. Ciao -

I'd be interested in a review of this brand/family by the "battery brains trust" https://www.fullspectrumpower.com/products/pulse-ipt-battery-p-14s Ciao

-

Did the Centy hiccup as well Chuck? Ciao

-

Yep the new bike V85TT. Ciao

-

Excellent, will be interesting to know if it has a positive effect. Chances are it won't but its a low effort zero cost situation. What could possibly go wrong:) Ciao

-

Does your hiccup docc? I don't think you can insulate EMI unless you use specific shielding. It needs more than just plug wire insulation I believe. Ciao

-

Might need to hold off on the "brilliant" it's just a maybe and possibly and be good if it was scenario. Ciao

-

I just had a thought triggered by an issue on the V85TT's caused by what appears to be EMI from the ignition coil affecting the crank angle sensor pickup cable. Causes erratic idle apparently and the Guzzi TSB fix is to re route the wire away from the HT lead I'm led to believe. I was wondering if anybody with the 3000 rpm hiccup as a chronic issue on their bike might like to see if the crank angle sensor pickup cable or connector is anywhere near the HT lead to the sparkplug. Looking at old images of the wiring on my bike before the engine swap the connector and cable were right next to and touching the r/h coil HT lead. Might be worth looking at and if it's close reroute the cable to keep it as far away as possible and see if there is an effect. ( the std cable has lots of length from memory) Ciao

-

Moto Guzzi V100 Sport Tourer: water cooled, 120 HP (26th of August 2021)

Lucky Phil replied to p6x's topic in Newer models

Yes, it's a major consideration on the track when changing gearing and ride height. Not sure how the new Guzzi will play out in this regard, a lot of the jacking issues from my experience with it on BMW K100's was as much to do with the rate of jacking as magnitude. In other words how it was controlled. Time will tell. Ciao -

There is no "correct" unless you are tuning for emissions and then there's a "range". There are settings that would make you look at the possibility that there was other issues worth checking. If it's running well at +18 and is not using too much fuel, warms up nicely and responds well to the throttle then I see no reason the change it. Ciao

-

Anyone knows a USA based companies that does Ceramic Exhaust Coating?

Lucky Phil replied to p6x's topic in Technical Topics

I like the first one best because. It's honest and says I'm a SS header/exhaust and don't see the need to hide it. It has "patina" It's not a hot-rod it's a motorcycle It costs nothing Being an air cooled engine the the last thing I want to do is insulate the header pipes for aesthetic reasons. It's doesn't look like the exhaust on one of those hideous bobberised calamities that, Manscaped, mun wearing, rolled up long pant, Latte sipping, inked up barrister's would ride. Ciao