-

Posts

1,010 -

Joined

-

Last visited

-

Days Won

43

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by MartyNZ

-

Mad bunny showed an oscilloscope trace of the sensor output here: https://www.v11lemans.com/forums/index.php?/topic/20673-mgs01-no-spray-no-spark/ It's a different engine, but the sensor is the same.

-

I always wondered what a worn cam chain and tensioner could do to affect timing of the camshaft and phonic wheel. Perhaps a loose chain whipping about could cause the glitches you see?

-

Could this show a defective RPM sensor?

-

While you have the ignition switch out, it is a good time to clean and lube it's guts. I have some ignition switch grease you can use.

-

Source for passenger backrest or luggage rack?

MartyNZ replied to Sleezyryd's topic in Technical Topics

Here is Ventura's NZ website if you want to order something direct from them: https://www.ventura-bike.com/product/moto-guzzi/V-11-Sport and the USA distributor is in California https://www.ventura-bike.com/distributors/13034 -

Yes. A power commander just alters the engine sensor readings going to the ECU. The ECU then (usually) injects more fuel based on falsified sensor data. There is a PC accessory that uses a wideband sensor to change fuel air ratios on the fly, which is a good thing, if you want to go that far. Some people like PCs, but they can become unreliable as they age. A Meinolf ECU map has improved injector and ignition timing, injector duration, and altitude compensation, so is better than a PC. That's what I chose anyway.

-

Ya go a couple of hours past the Ettamogah pub towards the black stump. If you get to the old Murphy place you've gone too far. There's bugger all out there. Take water.

-

I made a female housing using a TPS salvaged from a dead Fiat at a wreckers yard. I cut off most of the TPS, soldered on leads, some epoxy and heatshrink sleeve, and presto. The male plug is cut off the Fiat engine loom to the TPS. It looks like hell, but works well.

-

Those relays look OK. 30 amps is plenty of capacity. It would be worth getting a set if you have trouble geting Omrons. Try them and report back. That is what this forum is great for. One of the relays needs to be a 5 pin SPDT (also called SPCO) in a V11, and the rest can be 4 pin SPST. The relay sockets can take 5 pin relays in all positions, so you should forget the 4 pin relays. When you have a set of 5 pin relays you can swap then around on the side of the road when things on the bike go quiet or dark. Some people call this swapping relays trick "troubleshooting" but when it is getting dark and rain is threatening, the troubleshooting can look more like "wild flailing" to an observer. Just say to yourself "at least it isn't a Harley". Seriously though, as Docc said, the Omrons work well, and the relay base repair suggested by Kiwi_Roy solved a problem on my bike. After tightning all the spade connectors in the relay bases (a really fiddly job) some intermittent problems disappeared. I put dielectric grease on all the sockets before I put the relays back. Then I put some foam tape between the relays, thinking that it would reduce the movement of the relays in their sockets.

-

I lubed my rubber bits. I sprayed the cush rubbers and the pockets with molybdenum disulfide dry lube spray. Greg Field wrote about a good idea you can do to the cush rubbers here: https://www.v11lemans.com/forums/index.php?/topic/11820-making-a-cushier-cush-drive/&tab=comments#comment-125587 I think this link might be interesting too: https://www.v11lemans.com/forums/index.php?/topic/20331-cush-drive-lubrication/&tab=comments#comment-230956 For the spline to the wheel, you might think about Kluber Staburags NBU 30 PTM. BMW part #. 07559062476. Expensive but good.

-

So, Roper, you started with an inspiring comment, which gradually became advice on picking a pub fight. Awesome story telling there.

-

-

-

Brexit is still mithering on 2 years later, with UK politicians wanting to have their cake and eat it. New Zealand just had some bad news last Friday too. Our biggest mass shooting ever. A white supremacy nut killed 51 citizens and hurt lots more. The police caught him while he was on the way to kill more, within 21 minutes, without firing a shot. Good job NZ Cops! Then the NZ government, within 6 days, outlawed military style semi automatic rifles, and high capacity magazines. Now I'm a gun owner, but I think NZ failed badly not to copy Australia's lead on gun control 2 decades ago. Good job NZ Government! Even though it is too late for 51 citizens. Now we need to get to work on the reporting and treatment of haters who enable/encourage mass shooters.

-

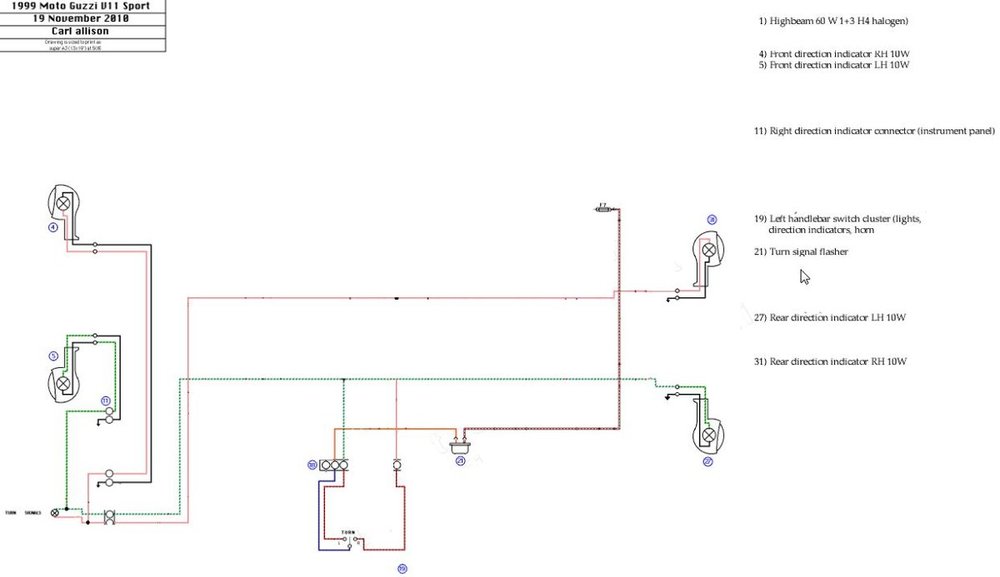

Docc is right (again). You need an electronic flasher [21] which will flash the indicator lights irrespective of current draw from the lamps. I did this, and found another problem. The instrument panel [6] turn signal light is connected to both left & right indicator light circuits, so if you have all four indicators fitted with LED lamps, all four lamps will flash when you indicate left or right turn. That [6] indicator provides a path to ground via the side opposite the side you selected. The fix is to replace the little incandescent bulb in the [6] panel with a facing pair of LEDS, with a common ground. Until I follow my own advice, I have only LEDs in the front indicators, same as Docc's bike. Note that I left out a wire in the diagram below. The red wire should go from the connector to the RH indicator lights.

-

From the album: NZ

2 V11s, a 850 T3, & a Griso on a ride to Little River for lunch. -

Injector cleaning by adding a cleaner to the fuel will help by disolving varnish/wax deposits, so can give good results. However some insoluable particles which get past the filter can lodge in the injectors, and only back-flushing or disassembly can clean that. I had brown fuzz in the inlet screens of my injectors, so I suspected some could be inside the injectors. I made two injector back-flushing kits, thanks to some help from Scud, and can mail you mine if you want to use it. ...and the 5 Dec 2016 post here: https://www.v11lemans.com/forums/index.php?/topic/18805-brand-new-scura/&do=findComment&comment=215317https://www.v11lemans.com/forums/index.php?/topic/18805-brand-new-scura/&do=findComment&comment=215317

-

Hi Nigel, I see a reference to a supplier here: https://www.v11lemans.com/forums/index.php?showtopic=20337&do=findComment&comment=231113 You may have to paint the red finish black for your bike.

-

As I understand it, you need several workshop manuals for the MGS01 Corsa. One for the original MGS01, and then another for the MGS01 Corsa which just covers the differences, but also states "the following information should be intended as variant to the Workshop manual - engine - for version V10 Centauro". The MGS01 Corsa manual refers to use of the V11 gearbox & rear transmission, so that leads to another manual. Gregory Bender made these manuals available here: - http://www.thisoldtractor.com/moto_guzzi_misc_workshop_manuals___shop_manuals___service_manuals.html

-

When Pete says something, it pays to listen. He has worked on Moto Guzzis before. Looking at your first post, it seems like pic 1 oscilloscope trace shows a lower sensor voltage and lower speed than pic 2. The SENS813 is an inductive pickup, which would put out lower voltage pulses if the gap to the phonic wheel was large. I think you could try reducing the SEN813 sensor gap to the minimum, and temporarily leave the o-ring seal out, just to check. As I see it, the sequence of events in the ECU are: 1. ECU Power on, self test, sensor check, and pump prime. 2. The ECU then waits until SEN813 pulses reach a "run" threshold. 3. The ECU will then turn on coils and injectors as instructed by the BIN file program. If the SEN813 sensor is faulty, or if the gap is too large, the ECU will not power the coils and injectors. As Chuck mentioned, electrical connectors can cause problems, and it is a good idea to remove and clean the connector to the ECU. What does your instrument panel RPM display show during cranking when it is sparking and not sparking? Be aware too that your manual says "If in the wrong position, the bank angle sensor may lead to sudden engine stalling". You mentioned this at the start, but you could try disconnecting it.

-

thanks Marty. but i already tried to air gap clearance. I have 5 each size shim. Can I suggest checking the gap by putting a bead of modeling clay or plasticine on the tip of the sensor, installing it when a tooth is lined up centred in the hole, removing and measuring the thickness. I know that it is easy to get that gap wrong, with shims and o-ring in the way.