-

Posts

2,642 -

Joined

-

Last visited

-

Days Won

64

Content Type

Profiles

Forums

Events

Gallery

Community Map

Posts posted by p6x

-

-

8 minutes ago, docc said:

So, is it lifting from the foot peg anchor? Or actually from below the bike ? (I could not tell from the video).

Such that the "footpeg" attachments are only to prevent tip-over?

It appears that the plates reach underneath the foot peg anchors, but you would not want it to slip from underneath.

I have asked the question, and we shall see if they have any feed-back tomorrow.

I found strange they don't seem to have photos of the system installed on a V11. I mean they must have tried it on a V11, no? or even, they could have asked one of their customer "with nothing but praise" to send some pics...

-

14 minutes ago, docc said:

That would be curious as we have never heard of them here, AFIIK.

If you follow the link he provided in the quote, and you look at the foot peg mount, you find that the plate that goes underneath the foot peg would reach underneath the anchoring of the foot peg.

Why not a U shaped support that you could slide underneath the foot peg pivot? the bracket is only there to prevent horizontal movement.

-

1 hour ago, Lucky Phil said:

So do I, Aviation, but I trust my own engineering. I wouldn't do anything unless it was safe. Belt and braces for me.

You know 20 years ago we needed a "special tool" to remove a component in the lube unit of the CFM-56 jet engines that powered the Boeing 737's in our fleet. We didn't have the tool and the lead time to get one was long and the Maintenance Manual showed a drawing and dimensions. So I requisitioned some material out of the stores system and took it home and machined/made a couple and took them to the tool crib for use doing the job. All worked perfectly for maybe 5 years then the Aviation world went totally compliance crazy. It was always quite strict but then it went totally full scale. My terrific and perfectly useful tools went in the bin. No official paperwork to certify their "compliance" sigh.

Ciao

I can relate to "home made" special tools. I was in the battle tanks industry, and a lot of the stuff we had to tear down after the tank had been used in the field could no longer come apart as described in the service manual. So we had to devise our clever ways...

-

3

3

-

-

1 hour ago, leroysch said:

Ditto.

Using the OEM stand and a scissor's jack under the sump, the bike is very stable. I've had the bike up/down/up/downon the lift, tank off/on/off/on, etc. with this configuration without a worry. Only pucker factor I encounter is the use of the OEM stand (with sockets to the appropriate bike nuts) raising and lowering the bike. I have a cheater pipe safety wired to the OEM stand...for reasons you can infer. (You would think an ex-flatbed owner/operator would have known better...)

I can understand using a cheater pipe.

The OEM stand is no longer available though. Because when I add up the costs of purchasing the on-bike lift + foot peg mount + shipping, then I come close to the price of a good scissors lift. Which I would buy without any hesitation if I had the space.

-

53 minutes ago, docc said:

That our V11 footpegs are folding would not be compatible with lifting through them?

Good catch Docc!

I watched their bracketing system again, and the only way it could work, is if they would lift from the pivot fixture, and not on the collapsible foot rest.

I am going to ask them to comment on that. Since he quoted they sold about 65 of those lifts to V11 owners....

-

1

1

-

-

-

-

1 hour ago, LowRyter said:

Yeah, that was my thinking, someone needs a freaking tire and no help. Admittedly, I sort of anticipated the whole deal. I wanted to use the tire up on this trip. But I was considering staying another day or two when one the riders told me about the Honda shop in the next town. I was just going to ride over there but he told me I should to call the Honda shop first. After that I called the other two places. Perhaps if I'd have shown up, they'd made an exception?

I believe showing up would have tipped the balance in your favor; it is obviously more difficult for them to turn you down when you are in their faces. It is always easier to be stringent when "protected". There is always the sympathetic component too. I mean these guys make a living out of those who like motorcycles, they should understand when it is time to forget about brands, and simply provide assistance.

I find that today, we make everything too "virtual", impersonal. I don't do that, but this is because I have time at my disposal. I don't phone the shop, I drop by. It is only 15 minutes, but I know that I will speak to the guy that works on my bike, and not the admin which does not really know what's the plan, and will possibly tell me something she made up to make me feel better.

In person is the best way. Although sometimes you may bump into someone who is not going to like you just because it is human nature; you can negotiate, and you know whoever you are speaking with is focused on the conversation, and not answering the phone mechanically while trying to solve the problem you just interrupted with your call, which induced him to get rid of you as fast as he could by just saying no!

-

29 minutes ago, droydx said:

It gets pretty warm inland from where I live on California central coast, and I've seen the guage register 100 F on several occasions. The calibration is done on my unit by rotating the thermal expansion coil so the needle reads the current ambient temp. There is a plastic backing inside the stainless back ring, which would seem to allow some degree of thermal expansion, although I think the silicon oil is fairly expansion/contraction stable under normal climate heat range.

Formotion shipped the set yesterday, I am just waiting for the instruments to reach me.

Yesterday, the temperature outside was about 102 degF in the afternoon. Today only 88 degF.

True about silicone oil. Most of the Bourdon tube pressure gauges we had were filled with silicone oil for pointer stability. We also used silicone oil in buffers, so there must be a reason.

-

50 minutes ago, LowRyter said:

That's my point. Now I was in rural Ark, Russellville had a Honda and Suzuki shop. Neither would touch my bike for tire change. All they needed to do was put it on shop stand. I had the "special" socket. The Honda dealer would only work on Hondas. The Suzuki dealer said they don't work on Ducatis. I found a shop in the hills that would do it but he didn't have a tire (the most common 180/55 size). Now I didn't go to Fayetteville where I likely would've had better luck.

My only point, is that traveling by bike, especially something unusual, like a Guzzi, a rider might not get the service expected or needed in an emergency. The shops are busy and don't need any new business. Now I had enough tire to get home and then some, if I'd had a severely worn tire, don't know. I've been on several trips where someone's tires were down to the cords (mine on several occasions).

wow! that bad...

What I find unacceptable is that the shops did not want to make an exception for a rider in need of help. I always thought that in case of emergency, people would help you. Or at least, this was my experience. But most of that was several decades ago; I suppose it is all different now.

You can never be 100% certain you will not need assistance along the way. You may be able to anticipate normal wear and tear, but in you cannot predict everything in advance.

I am going to verify with my insurance what they mean that I get a free tow to the nearest mechanic....

-

I got the replies from Boonstra; they have never tried the JMP lift on a V11 Moto Guzzi.

However, "on-bike" said they have sold many of their lifts for V11 Moto Guzzi.

Here's their answer:

QuoteWe have supplied in the region of some 65 Big Blue lifts to MG V11 customers worldwide including the USA and have nothing but rave reviews from them so all you need with the lift is our Heavy Duty footpeg mount set, You can find it here: https://us.on-bike.com/motorcycle-lifts/bike-lift-for-other-cruisersEverything is stock and ready to go on a 2 day DHL air service to the USA, All included in the price shown.Is there anyone reading this thread owning one of these?

Those of you with "motorcycle lift" experience, any opinion on the "footpeg" solution?

-

13 hours ago, Lucky Phil said:

The stability is controlled by the shop stand and the front lift support by the scissor lifter. It's stable. You can of course have a simple small wooden frame to locate on the sump when you use the scissor lift if your worried. My large holder was made for an engine change where I lifted the chassis over the engine on the lift bench and for engine storage. An overkill in all other situations.

Ciao

I come from the "type approval" certification and reviewed designed world. I wish I could find something designed specifically for the V11 series.

If I had the space, I would purchase a proper setup with a scissor lift and appropriate stands.

I found another prospective company in England, which I have not seen mentioned here, on the forum; on-bike.

They seem to specialize in motorcycle lifts. Obviously, nothing shown for Moto Guzzi.

They have a lift for the Ducati Diavel.

Boonstra has not yet replied about the lift proposed when I configure their filter for my Le Mans. I am going to check with on-bike to see if they would have anything.

-

56 minutes ago, 80CX100 said:

I find my other guzzis much more pleasant to work on, a big part of that is just getting it up in the air to do work.

The V11's style of frame, crossover, lack of center stand, and extreme rear weight bias, makes it challenging for me, to easily get things elevated safely.

The first time I tried to pull the rear plate out on my lift table to remove the rear wheel with the sump up on a scissor jack, the whole back end of the bike wanted to drop down into the hole. It was a pucker moment while I held the bike up and managed to get the plate back in place. Be mindful, V11s are very heavy in the ass end lol.

Right now I've got it up on a scissor jack under the sump, with a Becker Technik Lift (not impressed jmho) under the pork chops.

I'm not happy with the set up I have now, it's a work in progress; my scissor jack is worth it's weight in gold and in the future I want to try using that, and different sized axle stands, with a shaped pieces of wood on them, placed under the pork chop/swing arm area and sump, fwiw good luck

I have dropped my Guzzi already while maneuvering it to come down the small ramp that leads to my garage. This is entirely my fault. I could have sat as rider, instead of walking alongside while holding the bars. I had the stand deployed, I was on the right hand side. I thought if anything happened, I would push the bike away from me, and it would land on its stand. So the moment arrived, and I found the hard way the bike was too heavy for me to push away.

It fell on me. I was so fortunate to not have been pinned underneath. I only broke a turn indicator lens, and scratched the right bar end weight.

I also discovered I could not upright it by myself either. No matter what I tried. Getting underneath to push with my legs... Niente da fare!

So I am now looking at it with much more respect.

Back to our subject; the sump of the V11 is convex. The way it looks to me, if you enter one of those scissors lift sideways, the bike will still be wobbly. At present, I can only see the Becker Technik center stand making sense.

I am going to run to my favorite shop tomorrow, and ask what they do to secure the bike on their professional grade lifts.

The Boonstra site proposes this JMP elevator for the V11 Guzzi Le Mans. But you have to use the uneven sump to lift the bike. I am going to ask them if they have tried it at least.

-

On 7/16/2021 at 9:41 PM, LowRyter said:

I guess I should've mentioned that I was riding my Ducati 939 SS. It has a single sided swingarm and racecar-like nut on the rear wheel. I brought the dual sided socket but no one would entertain replacing a pretty standard 180/55 rear tire.

Anyway, just a note about riding an oddball bike on the road.

Do you mean the shops you contacted refused to change the tire because it was a Ducati 939 SS?

From what I understand, here in H'town, the shops would install and balance your tires, providing you bring the wheels to them. And even then, you still need to make an appointment.

My question is; what happens in case of emergency? say you are on the road, far away from your home, say you need to replace a tire, or your bike stops...

I have subscribed to AMA, and my insurance too provides transport to the nearest shop. But what happens if that shop does not accept your bike?

What do you do?

-

1

1

-

-

On 7/17/2021 at 7:43 PM, MartyNZ said:

This is good, but Dalton's law of partial pressures tells us that eventually other gasses will diffuse into a nitrogen inflated tire, so purging and re-inflating after several years could be needed.

but checking tire pressure is more important.

I can tell you scuba dive... using a re-breather possibly? constant ppO2?

I concur with tire pressure. I check mine before I ride.

-

-

On 7/16/2021 at 5:51 PM, O2 V11 said:

p6x, I do not think there is any benefit in nitrogen filled tyres. Never used it myself but if the opportunity arose I would not bother. On the other hand have installed angled valve stems front and rear. 90 at front and 135 at rear and yes both facing away from the side stand.

Rob

I checked and filled my pressure using my air compressor; while the rear was a walk in the park, the front was a bit of a struggle. I will probably replace the valves the next time I change the tires.

-

On 7/16/2021 at 5:45 PM, Pressureangle said:

If it costs nothing, it hurts nothing.

It was dealership gravy in the RV industry, and I got rather disenchanted with the unethical propaganda they used to sell it. They charged something like $25/tire 15 years ago. If it's free and convenient, I'd use it myself. There is no downside.I think Costco has done it across the board in the USA. Self serve N2 stations. As I said, it does not matter to me if it is air or N2. I am concerned with pressure accuracy.

-

17 hours ago, docc said:

The V11 factory stand only lifts the rear. Awkwardly. Once on the factory stand, the front can be lifted with a platform jack under the sump. PLEASE be certain the platform is fully seated under the sump, not lifting from an edge or a corner. And PLEASE either tie your V11 down to the lift or to joists above ("chain fall").

With both wheels off the V11 on the factory stand and sump on the edge of a platform scissor jack, you are halfway to a bad day. Don't ask me how I know.

It looks to me that lifting the whole bike from under the sump is not really helpful, as it would possibly interfere with the oil filter access, should you want to service it?

I got the answer from Abba, and it is rather laconically formulated: -"sorry, we don't do anything for Moto Guzzi!"

If I understood all the entries here, the safest is to purchase a rear stand, a front stand, and if I want to work on the bike at height, I need to purchase one of those scissors platform?

-

1

1

-

-

31 minutes ago, docc said:

Yep, this one is from the Netherlands. Easy....

-

2

2

-

-

6 minutes ago, docc said:

The V11 factory stand only lifts the rear. Awkwardly. Once on the factory stand, the front can be lifted with a platform jack under the sump. PLEASE be certain the platform is fully seated under the sump, not lifting from an edge or a corner. And PLEASE either tie your V11 down to the lift or to joists above ("chain fall").

With both wheels off the V11 on the factory stand and sump on the edge of a platform scissor jack, you are halfway to a bad day. Don't ask me how I know.

I am guessing I am not going to try to be "too clever", I already dropped the bike by doing something stupid that served me as a lesson.

I am going to get something that is safe to operate, or I will let the guys at MPH do the heavy lifting.

-

3 minutes ago, Lucky Phil said:

Well I have the ability to learn but it's like playing a guitar like an expert it takes many many hours before it's like an extension of your body. I used to set up the Mill to do work I wanted and anything remotely involved I would get him to do as I didn't want to wreck an expensive part due to a lack of skills. it never helped my confidence when I watched a master like him work the X/Y manual feeds together smoothly and with finesse. I knew then that I probably don't have enough years left to ever become that good and it be second nature.

Ciao

I can attest that it is easier to play guitar as I do that too; but I understand what you mean. I remember how we learned at school, by first doing simple stuff, such as cutting a parallelepiped block to quotes. First starting with raw material, and then taking one already started, and installing it properly. Of course, it takes time to make it just natural. There is a lot of arithmetic to absorb to. Especially if you wanted to cut your own gears, using a divider.

-

2

2

-

-

On 7/16/2021 at 4:40 PM, droydx said:

My Formotion gauges are 10+ years old on my 03 Rosso...... have held up well even with just stick on tape and velcro mounts on my fairing inner. I have to change clock batteries about every 12 - 18 months and I just recently had to refill my thermometer with silicon oil, which was easy to do, and recalibrate the temperature. Quality stuff!

Andy

Hopefully, the newer technology will decrease the frequency at which you need to change the battery on the clock.

I am not yet settled on what I am going to do to install the gauges. I thought about doing what you have, having them at the back. But I am waiting to have them on hand, with the "mounting bar" fixture, to see if I can put them closer to me.

Calibrating a mechanical temperature gauge is not easy.

Speaking of Silicone oil, I am hoping they have thought about expansion. With the temperature fluctuations we have in Texas, I am afraid that I will find the gauge leaking oil. So that may be a reason to have the mounting as you did it, so the gauge is less exposed to the ardent sun we have here. Or I will maybe need to have some kind of cover?

-

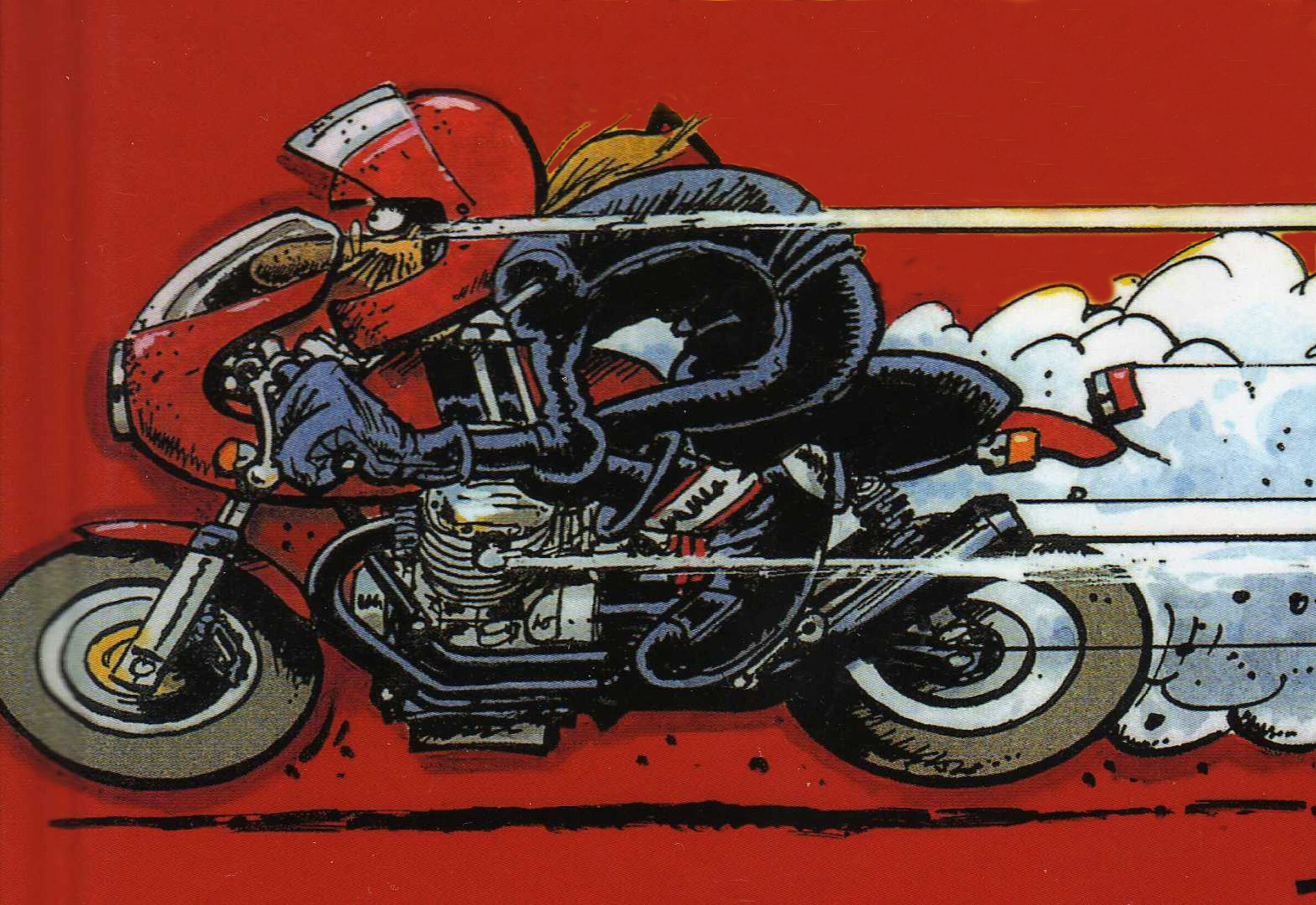

Gratuitous Pics of Girls + Guzzi

in Special place for banter and conversation

Posted

I hope that I am not going to offend anybody....

This is an old "for adult cartoons" French magazine, which only cost six Francs, so a very old one indeed. As you can see, the choice of the bike and individuals correspond;

Prolo is short for Proletaire or Proletarian in English... the guy wears an overall, which symbolized that.