-

Posts

5,449 -

Joined

-

Last visited

-

Days Won

276

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Lucky Phil

-

Simple docc just but some cold bluing solution they use for guns and follow the instructions. Ciao

-

Lipstick on a Pig? no I don't think so. For me it's not about the weight saving but the suitability of the material for the job and the fact that they will still be looking exactly as new in 50 years unlike the std passive plated ones. SS is a poor fastener material and only really applicable to boats and structures where weathering ability is foremost. I've never seen an SS fastener used on an aircraft in 45 years or a racing motorcycle for that matter. I've seen manufacturers such as Ducati use them for cylinder stud at one time and they always broke to the point that I think there was a recall for them. Horrible stuff for a fastener that needs to stretch to maintain tension. Ok for nuts though. With using Ti stuff you spend the money and swap out fasteners and label the std stuff and where it was used and if you ever sell the bike then spent a few hours putting the std fasteners back on and re use the Ti stuff on the next bike. I actually re blacked mine when I had the plates off for painting. I couldn't get the right head in M10 Ti bolts at the time so left them standard. Ciao

-

Fork oil doesn't change it's viscosity like engine oil docc, it's life is too easy to worry about that and it doesnt have any viscosity improvers in it, it just a straigh weight oil. It may be a little more viscous due to particulate contamination but if you take it from the top and let it settle for a few hours then it wont be affected. Fork oil will never see 100 deg C docc so that's not an issue and depending on the base weight variations then there will be a Cst variation due to temp changes as well. Ciao

- 40 replies

-

- 1

-

-

- rebound

- compression

-

(and 1 more)

Tagged with:

-

- 40 replies

-

- 1

-

-

- rebound

- compression

-

(and 1 more)

Tagged with:

-

Remember my advice from a while back here docc. Do a viscosity test of your original fork oil BEFORE you change it out so you know what the starting point is. take a small syringe without the needle and plunger and fill it to a level then let it drip into a container while timing the drips. Then take your oil of choice in whatever weight you decide and do the same so you verify that what you're putting in is actually the way you want to go. Who knows what weight oil is in the forks and importantly all "weights" aren't necessarily the same. Can save a lot of messing about and expense. Ciao

- 40 replies

-

- 2

-

-

-

- rebound

- compression

-

(and 1 more)

Tagged with:

-

No I've never seen a TI kit for a V11, I've just ordered them individually. You'd be surprised it doesn't take long to figure out the lengths you need as the majority of cap screws on the V11 are M6 and M8 so its the length that's the major consideration. Most of my bike is now Ti fasteners and it's just evolved over the years to be that way. I still use steel on the rear shock and engine mounts. I used to buy all mine from Toronto Cycles but there's plenty of decent quality Chinese stuff on ebay these days Ciao

-

Just update it to handlebars mounted to the top triple clamp and a peg lowering kit if necessary. Ciao

-

Starter Woes on New starter. Loud Buzzing Relay

Lucky Phil replied to ColdandWet's topic in 24/7 V11

Ok that is the neutral switch wire. My suggestion was simply a check. I dont even know what the effect would be if the neutral wire was hooked to the starter, probably nothing but its one of those things you just ensure is correct almost unconsciously when you have an issue. The small blade connector on the starter is the power wire from the relay that operates a solenoid inside the starter to engage the main starter contactor. Ciao -

Fork oil weight has no effect on sag. Fork oil level possibly can depending on how overfilled it is. I'd check the level first. Ciao

- 40 replies

-

- 1

-

-

- rebound

- compression

-

(and 1 more)

Tagged with:

-

Starter Woes on New starter. Loud Buzzing Relay

Lucky Phil replied to ColdandWet's topic in 24/7 V11

Here's a silly question just off the top of my head in case you have had other stuff apart as well as the starter. You don't have the neutral switch wire connected to the starter connector do you? Ciao -

Starter Woes on New starter. Loud Buzzing Relay

Lucky Phil replied to ColdandWet's topic in 24/7 V11

You'll need voltage onto the blade connector as well docc. Ciao -

Starter Woes on New starter. Loud Buzzing Relay

Lucky Phil replied to ColdandWet's topic in 24/7 V11

Have you removed the starter and tried 12 volts to it directly to see if the new starter is working?That would be the first thing I would do. Just because it's new doesn't mean it isn't faulty. Ciao -

Or here https://www.euromotoelectrics.com/category-s/1666.htm Ciao

-

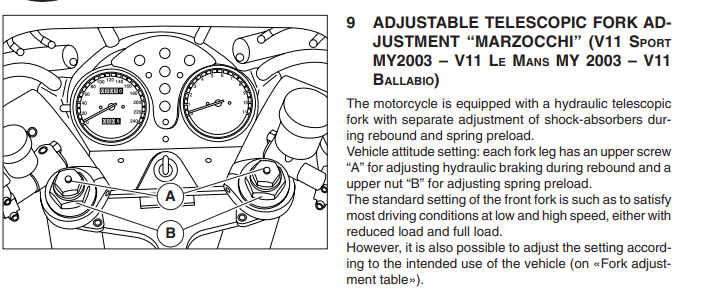

When in doubt look at the shop manual. Looks like you have an earlier owners manual. The transition of components for Guzzi isn't a hard line and so neither will be the owners manuals. Ciao

- 40 replies

-

- 3

-

-

-

- rebound

- compression

-

(and 1 more)

Tagged with:

-

ANSWERED Oil pressure warning light - start up

Lucky Phil replied to 4corsa's topic in Technical Topics

Yes when I caught up on the thread I thought that might have happened. Would never have happened to me of course, I'm to much of a "one tracker" as my wife keeps reminding me:) No side roads and one catastrophe at a time, then move onto the next. That's me. Ciao -

ANSWERED Oil pressure warning light - start up

Lucky Phil replied to 4corsa's topic in Technical Topics

Wow 3 pages of pulling the bike apart and I had the answer in the second post. As I said then, if the wire hasn't fallen off the switch and the light comes on if you ground the switch wire and turn the ignition on then its the switch. Ciao -

Good point, not sure. Couldn't hurt. Ciao

-

Std K100 tool kit docc http://www.verrill.com/moto/rants/2010/100325rant.shtml Ciao

-

I've owned a couple of K100RS's over the years docc but can't remember this tool. R U shore it's part of the std kit? Ciao

-

Well the reg converts excess output into heat but how much heat is the question. Sound a little too hot to me but others would have a better idea. BTW everyone these days should have a temp gun in the home/garage, you know those hand gun style thermometers you point the infared dot at and it tells you the temp of the part or even person you are pointing it at. This way you could tell us all the exact temp it is and we could compare it to our units. I use mine all the time esp in these Corona days. They cost bugger all to buy now so everyone needs one. You have your orders:) Ciao

-

Kiwiroy has posted some wiring diagrams and information here for this issue I think. Ciao

-

You know I'm warming to these a lot. It's not often you see a GT style bike that actually still looks good with cases fitted. These days 110 hp on the road is plenty for me. Ciao

-

Very good, congratulations. Late January for me, a grandson. Yes it sees so. I hadn't noticed this for the 10 years I've had the bike. Interestingly Guzzi dont even list the screws in the parts manual as separate items. Ciao

-

Follow docc battery conditioning thread procedure. I leave mine hooked up to a trickle charger but only turn it on monthly for a day and then off again. Ciao

-

After reading your post Meinolf I checked my Centauro and V11 throttle bodies and Found that on the lower aluminium cross brace the Daytona uses all countersunk screws and the V11 has countersunk screws on the right side and standard cap screws on the left. Not sure if this is standard but maybe somebody has had the TB's off my old standard engine in the past and did what you suggested. I was going to refit the throttle bodies and then both cross braces so I'll look for misalignment and apply your advice. Your first Grandchild? I'm about to have mine soon. Ciao