-

Posts

5,449 -

Joined

-

Last visited

-

Days Won

276

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Lucky Phil

-

Just buy the top of the range Wilbers shock. Adjustable everything. H/lo speed compression, hydraulic preload adjuster, low speed rebound and shock length. The preload adjuster and reservoir fit the std Sachs mount. Phil

-

teslas killing Motorcyclists

Lucky Phil replied to KINDOY2's topic in Special place for banter and conversation

Without a doubt. Phil -

teslas killing Motorcyclists

Lucky Phil replied to KINDOY2's topic in Special place for banter and conversation

Ha doesn't seem right! Here's another fact for you. To go to a full electric/renewable economy the world will need a 400% increase in the mining and production of Copper alone over and above what we currently produce. It takes on average 17 years from inception to digging the first ton of ore for a copper mine and the people that want to close down fossil fuel energy production are also the people that want to close down mining! Ever seen the steel and concrete used in anchoring down a wind turbine? Go and look on youtube at that and count the energy costs. To give you some idea its a hole in the ground about 75 metres across and 30 metres deep full of concrete and steel reo and we haven't even got to the building of the tower and generator which are high maintenance items even land based. The blades are life limited and currently are disposed of in land fill! Utopian dreaming. Phil -

Design perceptions, what a topic. There is something to consider in the design and aesthetics of just about everything and this is it. Am I emotionally responding to something that's is beautiful and in harmony with the overall concept or am I responding to it just being "different". The latter doesn't stand the test of time where the former does. Phil

-

Moto Guzzi V100 Stelvio 2024 - Updated 11-Dec-2023

Lucky Phil replied to p6x's topic in Newer models

Never going to happen I'm afraid. Phil -

Moto Guzzi V100 Stelvio 2024 - Updated 11-Dec-2023

Lucky Phil replied to p6x's topic in Newer models

If you want to get the definitive aftermarket exhaust option design wise for the V100 then wait for Akrapovic to offer a full system. They are the gold standard in exhaust design and quality in my view. You can't believe how well an exhaust system is made and fits until you've had a full Akra system in your hands and installed one. Phil -

Moto Guzzi V100 Stelvio 2024 - Updated 11-Dec-2023

Lucky Phil replied to p6x's topic in Newer models

What are Agostinis thinking. You could drive a truck between those new header pipes and the cylinder block. Nicely shaped and tucked in they are not. A tighter bend to get the pipe closer to the block and tucked in won't have any affect on the performance gains if there are indeed any at all. As for the sound, far too loud. If it sounds loudish revving at a standstill on a whiff of throttle then under load with the throttle blades really open it will be obnoxiously loud. The clue is in the size of the muffler. You can't efficiently silencer a 1000cc twin with a muffler of that physical dimension. It saves weight but the trade off is noise and headers that stick out like a set of crash bars. Phil -

Those serrated lock washers are appalling horrid things and along with spring washers I refuse to use them. Phil

-

Was that the spooge docc? Have you ever replaced/checked the sealing between the tank flange/cap adaptor and the tank itself? This is what the old caps seal looked like ( not the OEM cap but another ebay cap) the flat seal they use is Nitrile and over compressed. They don't last for anyone thinking of using an ebay cap. They either do this or swell and distort badly. FKM material is the solution as usual and getting the compression of the seal correct.. Phil

-

New tank cap. Required a bit of modification to work. I made up a new FKM flat seal as the originals don't hold up. A new vent tube in fuel proof tube as the original clear tube isn't fuel proof, some standoffs to get the compression of the flange gasket correct and a 2mm flange washer to get the distances and seal compression correct on the main seal. These Chinese caps are cheap and well made although they are short on the design details that are important for a proper fit that seals correctly. You won't be aware of this until one day if the bike falls over or you fill the tank too much and you get fuel leaking everywhere out of the cap assembly. Titanium fasteners, naturally. The last thing you need is fuel leaking out the cap assy onto a hot engine in the event of a silly tip over. Phil

-

I've seen footage from a bunch of different angles and any other rider would have been given a long lap penalty no doubt at all. He's a bit like Johnny Rea in WSB, a protected species. Phil

-

Buy yourself one of these. With a pair of AEW stainless silencers as shown it'll be about 90lbs lighter. Smooth as silk, abs, low C of G and parts are dirt cheap. Quality is very good. Can't go wrong.

-

I've seen flow rate comparisons between Chinese injectors of the same type and design to check consistency. It wasn't impressive. I'd spend the money getting originals cleaned if possible or if using Chinese injectors I'd buy twice as many as you need and get them flow tested and best matched. There's a reason they are dirt cheap. Phil

-

When you own a Guzzi you need a good workshop. You'll be spending a lot of time there. Phil

-

The probable reason for this is because now the clutch is correctly bled and this is what a normal V11 clutch feels like. Air in the system with make the action spongy and increase the clutch engagement/disengagement zone. Phil

-

None of this concern is really an issue. If you disassemble the original electric tap you will find a 12mm outlet hose size fed by 6mm internal passages in the tap itself. The 12mm outlet dia of the tap is only there to match the inlet dia for the external pump they chose so the hose is the same size both ends and doesn't need to be a "special" with different end dia's. The original external pump is way oversize for the application anyway as later in tank pumps demonstrate. As we all know the theory demands in any pump application the inlet be of greater flow than the outlet but nobody told Guzzi this so the original electric tap set up is for all practical purposes a 6mm inlet with a 12mm delivery. It works just fine that way. Once again the practice and the theory don't align and in those circumstances I'm happy to go with the proven practice. Using a std size tap outlet would be fine with regards to fuel feed but you then need a hose reducer between the pump inlet and tap outlet which is an easy thing to machine up BUT the length of the hose between the tap outlet and the pump inlet is so short you can't afford to have any section at all of that hose with a length of even a little rigidity due to an inline reducer/step up fitting. Having an additional length of smaller diameter hose looped to accommodate a step up isn't practical in that area either. Not enough real estate. Phil

-

2004 cafe sport model …. Question ( please forgive me lol )

Lucky Phil replied to arveno's topic in Technical Topics

I just think of this stuff docc because I never commute anymore and all the miles I do on cars and bikes are either freeway or country roads pretty much. No point me testing anything in reality. Brakes, tyres, clutches etc last for ever with my vehicles. Maybe wheel bearings I could comment on if you have decades to wait, lol. Phil -

Problem with that theory is the 99-2000 parts manual shows no clamp and the 02-2007 I have shown has a clamp that's never been fitted to any model as far as I can see. So it's not an outdated carry over from a previous manual. The original image posted may be an even later iteration or amendment to a mistake in the manual. This is why in the aviation world the parts manual was never allowed to be a legal reference for the assembly of aircraft components, it was a part number sourcing reference only. Never to be used to demonstrate assembly order. Phil

-

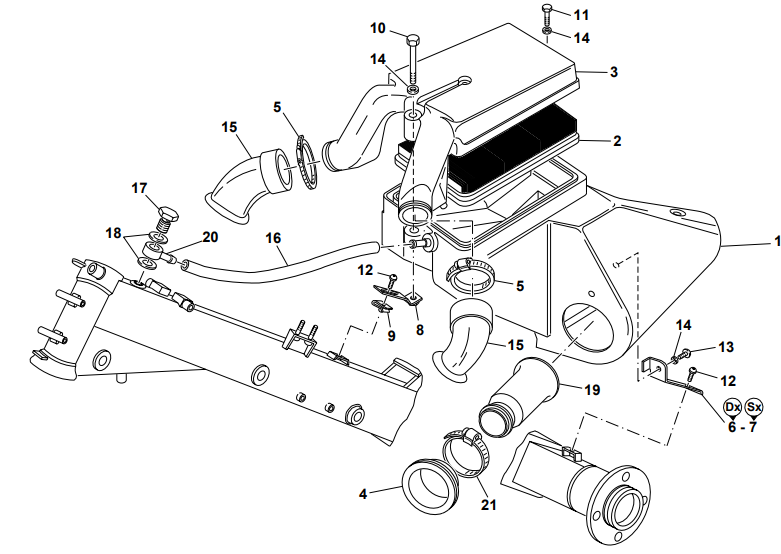

Parts manuals. Here;s another version of the parts manual. Has anyone ever seen item 19 fitted on a Guzzi V11 Sport? It's not the part number for the clamp that connects the trumpet sleeve to the throttle body either. Parts manuals, they can be misleading sometimes.