audiomick

Members-

Posts

2,986 -

Joined

-

Last visited

-

Days Won

61

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by audiomick

-

Lots of nice bikes in there, and the scale of the event is really impressing. But... tell your British mate that he should learn a bit about editing videos. The train crash edits get very annoying very quickly. Hard editing the video is "modern", and can be acceptable, but the clicks in the audio at every edit are not. Getting it right isn't hard. Fade out and in, or crossfade. Most editing programs have easy to use functions to achieve that. EDIT: and tell him to find out where the microphone on his recording device is, and stick a bit of foam rubber over the hole. Getting rid of the wind noise is not that hard either.

-

Good plan.

-

That brings to mind the Ford Falcon GTHO Phase III. For the uninitiated, that was an homologation special based on a four door family car in the early '70s to race in a particular touring car class in Australia. Even though I'm more on the Holden side of the Ford-Holden debate, I have to admit it was a very, very interesting car. There was some special stuff on them, but nothing that couldn't be sourced after-market after a few years. The point is, sometime in the late '80s or early '90s I heard that there were substantially more of them currently registered than were ever produced. This is one, althought the yellow colour was not that commion, I think. I always think of them as white (with the stripes), or maybe red. By Sicnag - 1972 Ford Falcon XY GTHO Sedan, CC BY 2.0, https://commons.wikimedia.org/w/index.php?curid=40645949

-

Well, I'm not jealous. Not at all. Really. Weellll, maybe a tiny bit... One thing though: why is the Roper Plate hanging on the wall instead of doing it's thing in a bike? Ok, mine is not installed yet either, but I don't have a workshop like that for myself alone, and I still go to work for a living.

-

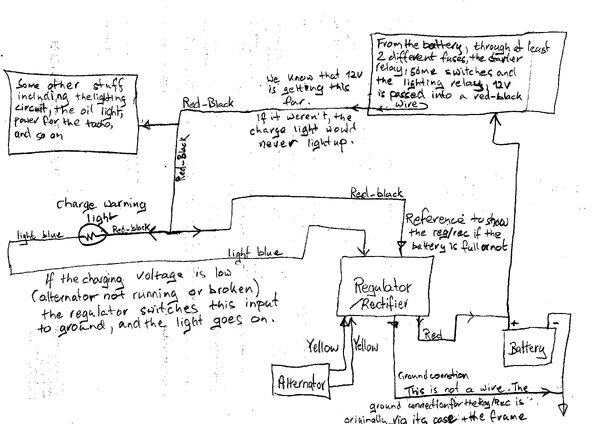

Yes. The safety margin is that, as I wrote, the bolt wont fit between two teeth, and I also ground off the end of the bolt so it is dead flat, no taper in to the thread. So even if just the very edge of the bolt is on top of a tooth, it should still take a good measurement. But that is just the safety margin. I made sure that a tooth was in the middle, and am quite sure my bolt was hitting it squarely.

-

I didn't worry about TDC, but did have a look at where the teeth on the wheel were, i.e. a tooth there where the bolt in the tool was landing. On top of that, I had a good look at whether the M5 bolt that I was using in "my" tool to measure the distance would fit in between two teeth on the the wheel. It wont. I took a measurement, and went in with the vernier caliper to check plausibility. Then put the bike in 2nd gear and bumped the motor a bit. Took another measurement, and came up with the same result. I'm pretty sure that the measurement is solid.

-

Yeah, I think it has a bit of a bulge. I have a replacement, so I will most likely just replace it. Might test it, but the power in the garage is photovoltaic, and doesn't have enough bumps (German word...) to power the hot air blower. Maybe I'll have a look at it at home in the kitchen when the girlfriend is at work.

-

Indeed. @swooshdave , please keep us posted on what you find.

-

Tom, that is very pretty, but I don't have the machines to make something like that. Fortunately, one of the blokes that shares the garage with me bought a drill press a while back. With that, I can drill holes in bits of metal that go really straight through. The rest of it was done with hand tools. I also liked the idea of a tool that can be screwed on to where the sensor sits. A bit of a fiddle to get it on and off, but security that it is really sitting where the measurement is to be made. Whatever, I'm happy with the result. Others have "better" tools for the job, but mine does it well too.

-

A brief excurse back to the V11: today I made a tool. On the way home it occurred to me that I now know what I wanted to measure, and may well never need the tool again. Still, making it and seeing that the idea worked was satisfying. Anyway, this is it: Using that, and cross-checking for plausibility with the vernier caliper, which can do depth measurements, I was able to establish that the old timing sensor is more or less the same length as the new one, i.e. 30 mm. The distance from the seating surface to the toothed wheel is 29 mm, and the sensor had two 1mm shims fitted. So the gap was 1mm (verified by holding the sensor against the tool and sticking a feeler gauge in between). That is, according to what someone further up quoted from the good book, within spec. Nevertheless, I'll try and get a 0.7mm shim to get it down to around 0.7mm. PS: I was a little disappointed. I had kind of hoped that the sensort would be deformed and the gap far too much. That would have offered an explanation (maybe) for the poor running.

-

From the album: audiomick

-

From the album: audiomick

-

From the album: audiomick

-

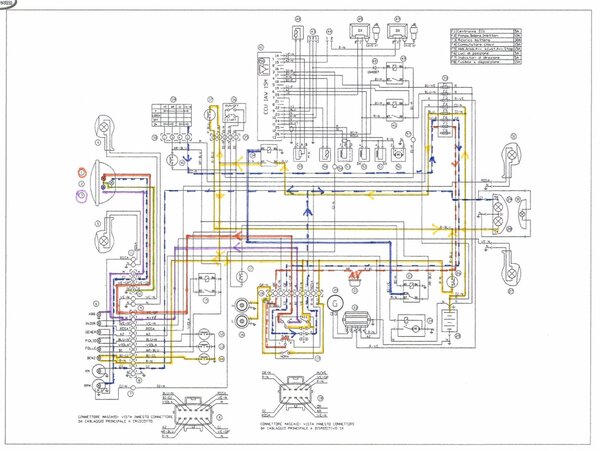

Why not? If you can deal with Guzzi electrics, reading music should be easy as pie.

-

Well, you may find it hard to believe, but Zappa was always radical, adventurous, experimental, brilliant, but strictly tonal. If you want atonal, try this. And that is not his most radical piece. : There are also things like this And Schönberg was a pioneer, but he was not alone.

-

I beg to differ. The "rules" of western tonal music adhere to strict rules that are based in physics. Believe me, I have a Bachelor degree in music with a focus on 20th century music. Quite apart from that, it seems to me a paradox that the U.S.A. staged an heroic revolution to release themselves from the yoke of british imperialism, but didn't go the whole 9.144 metres and adopt the much more logical and sensible system that was proposed in France about a century earlier, and finalised about the same time as the revolution. PS: Australia is still nominally a "British Colony", but the sensible system of measurement was adopted about the end of the '60s, when I was about 7 years old.

-

Well, yes, as well. https://en.wikipedia.org/wiki/Metre_(music)

-

Yes, I understood that. But what about sensible units, you know, millimetres and so on. Yes, I'm too lazy to look it up...

-

Fantastic. Can I use that? It would be very often useful to "explain" the behaviour of sound equipment.

-

As far as I understand it, no "tuning" effects. Either it works satisfactorily, or it doesn't, i.e. under a particular value, the pulse is too weak. Above that, it is enough, but "more" doesn't make it better. The ECU sees the pulse, or it doesn't. What is that in sensible units?

-

That depends on the fault. Assuming it did have something to do with that switch, the bike ran again later, so it can be considered an intermittant fault. I gather the bike was rolling when it died. So if the switch was cutting in and out, the momentum could easily have "push started" the bike a couple of times before it finally died. All crystal ball stuff from here, but it seems plausible to me. Since you worked on and around the switch recently, and now the motor is cutting out, I would definitely have another look at it and make sure it went back together properly.

-

Firstly, and easiest to check: the switch on the side-stand, the switch on the clutch, the kill-switch. All those "safety features" that will stop the motor if they have a fault. Check them and make sure there is nothing dodgy, and take it from there. Oh, and have a look inside the ignition switch. After that, the relays, primarily those involved in the safety features. But as @gstallons already wrote, there is a whole list of things it could have been. Maybe even "only" a bit of water in the fuel tank.

-

That'd be good, if you could do that. I'm pretty sure it is in the workshop book somewhere, and will look there, but confirmation from another source is always helpful.

-

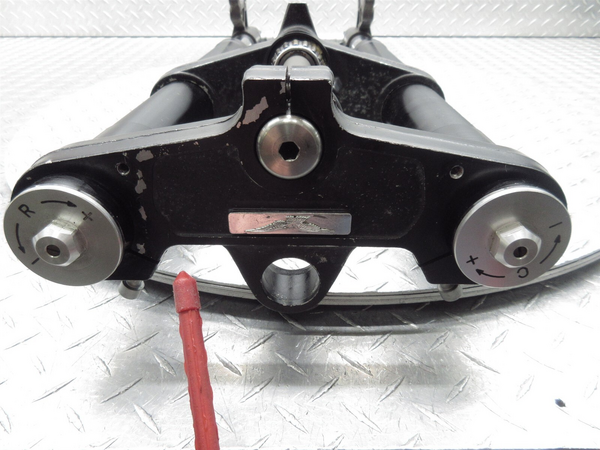

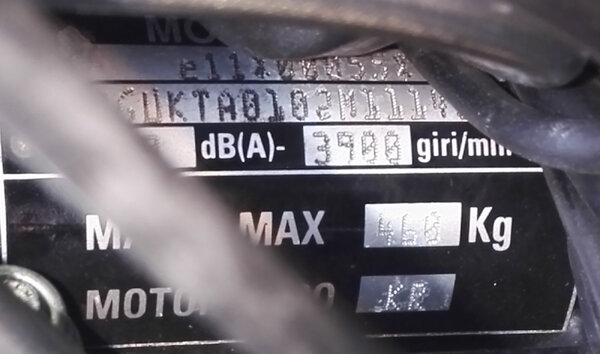

Today I took the timing sensor out. Lots of buggerising around: I replaced the breather hose that runs under the spine from the headstock to the back of the motor a while back. It seems I made a "tactical error" in the process. The cable from the timing sensor went up between that hose and the frame, and the connector was hidden under the airbox. The result was that getting the sensor out involved "unclothing" the Le Mans all the way down to unfastening the airbox. When it goes back together, that plug will be nicely accessible on the frame just above the sensor, don't you worry. The sensor didn't look too bad, but it will be swapped out. Holding the new one against the old one, and assuming they were both the same length in new condition, it seems the old one has swelled and shortened such that it is about a half a millimetre shorter than new. That would be enough to take the gap from (assuing it was correct) about 0.7mm to about 1.2mm. Going by what I have read here, amongst others from @guzzler's report on the subject, that would be enough to make it run badly. Whatever, the new sensor will go in. Cleaning up around the sensor was a pain. There were liberal amounts of some sort of silicon sealant involved, and getting that all cleaned up took a while. Since the airbox is now unfastened, the list of "things to be done now" has grown again. I wanted to just put the new sensor in, and see how that affects the way the bike runs. Since I'm so far in now, it seems sensible to go at the "tank off mainenance" thing again from scratch. I've been through that once already, but it was all a bit perfunctory. Since I've got it all apart again, it seems sensible to go at it again and take a bit more care about it. Cleaning the throttle bodies really properly, for instance, And I've got some new rubbers for between the throttle bodies and the motor. And I've got a new timing chain here, and whilst I'm in there I could repair the two broken screws of the four that hold on the alternator cover. And the tailpiece is off, to make it easier to get to the screws for the sidecover. Since that's off, I could have another look at the wiring under the seat, particularly on the underside of the relay sockets. And while I'm in there, I could consider adding the additional relay to supply direct power from the battery to the starter solenoid. The fun never ends...

![IMG_20241123_224923[1].jpg](https://www.v11lemans.com/gallery/monthly_2024_11/small.IMG_20241123_2249231.jpg.e096b44fe99686a032b551bbf1bb4264.jpg)

![IMG_20241121_231155[1].jpg](https://www.v11lemans.com/gallery/monthly_2024_11/small.IMG_20241121_2311551.jpg.6d864d972198380bf13530b1452c1fe4.jpg)