-

Posts

5,449 -

Joined

-

Last visited

-

Days Won

276

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Lucky Phil

-

Yep but about 6 or more years ago off Ferracci Ebay site. Still have them in my spares box but I'd go the Kibblewhite black diamonds as I mentioned before. The coated valves have way less friction than the SS valves and so less guide wear. Even on the bench you can feel this, by inserting a valve in a guide and applying some side load and moving the valve you can feel the reduced resistance. Ciao

-

^ +1 Pete, locking tabs are missing. These are the ring nuts I need to borrow your sockets to torque up Pete. Ciao

-

This is correct.To get the overall gearing and relationship to the engine speed you need to add the gearbox gear ration of whatever gear you're looking at assuming the tyre circumference is the same. Ciao

-

Its 11/32 docc. 2.9 to 1. Ciao

-

I dont think I use 5th until around 80-90kph.(50mph) If your bike wont pull 5th until 85mph then there's an issue with your bike. Probably needs a tune up and throttle sync. All the V11's are the same final drive ratio. Sounds like you may have the same issue as others that have migrated from Japanese 4 cylinder bikes to twins like Ducati's esp and feel they need to be in 5th or 6th gear at moderate speeds. Around town my Guzzi and Ducatis spend most of their life in 3rd gear. The issue with shorter gearing is then you have an absurdly low 1st gear. Ciao

-

Yes I agree, and I'm aware that values are a personal thing. I was aware of the pieces origin however I thought the member had them made by a third party. My point still remains though for a piece of printed plastic they are very pricey. Not that I would ever go down the pod path but my value system would price point them at $100. Just for comparative purposes and no doubt make a target of myself. Ciao

-

$252AUD, for 3D printed plastic! I thought the advantage of 3D was cheap and fast. Ciao

-

Replace the valves and K-line the guides. The Ferracci valves are 1/2mm oversize from memory. I bought a set on ebay years ago. Personally I'd go for Kibblewhite black diamond valves which are gas nitrided. Way less guide wear with them and a US company as well. http://shop.kpmivalvetrain.com/c/sport_moto-guzzi_all-2-valve-big-blocks-1971-2012_valve-black-diamond Ciao

-

Dont bother, its a lot of work with the wire wheel,wet and dry, scotchbright etc and they just end up the same way before you know it. Ciao

-

Not at all, I've personally never used a torque wrench on exhaust studs or nuts for that matter in 50 years. As a matter of fact I dont use a torque wrench all that often. Just for critical fasteners and groups of fasteners that need to be tensioned evenly. The reality is its not a very accurate way to tension a bolt its just that its better than free hand for the overwhelming majority of people. Get rid of the spring washer though, they are an embarrassment. Whenever I see spring washers i think "someone got the engineering wrong then".Buy a couple of Nord-Lock washers. Ciao

-

Ok Pete thanks. Did you see a member here recently had his gearbox shifter sleeves ( or movable hose as the manual calls them)replace during a gearbox rebuild and the rebuilder fitted sleeves that ended up too wide and the box wouldn't shift. Dont know why the sleeves ended uo too wide but it seemed one of the possibilities was that they were incorrectly manufactured. Just something to look for if you need new shifter/drive sleeves. Ciao

-

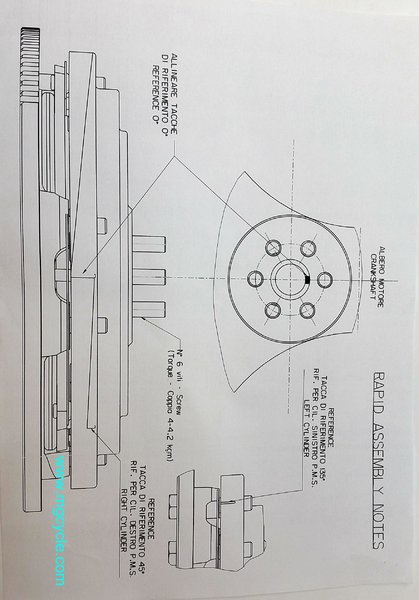

No worries Pete. I just measured my old style RAM plate thats fitted to the Daytona engine that's finished on the bench. It has the fast wearing plate and I measured it at 5.75mm thick. Bear in mind that I couldn't get the calipers in there as its all assembled so I used the Plasticine impression technique and measured it with the digital calipers. I have a pretty high level of confidence in the measurement. You wouldnt happen to have the two special tab sockets that fit the internal ring nuts on the 6 speed box shafts that I could borrow do you? p/n's 01 91 38 30 and 01 91 37 30. 28 and 24mm I believe. Ciao

-

Nice find. The torque should be the same as any grade 8 or 9 steel bolt as the torque is determined by the bolt/stud material not the nut material. You need to stretch the stud to maintain the tension so if the brass nut cant cut it then you need to go to steel or Titanium. I'm sure the brass nut will take the torque though esp if you opt for the extra long ones to give greater threaded surface area as thats the idea. Personally I'd go with a Titanium nut and anti sieze. Ciao

-

Fifteenth South'n Spine Raid 2019

Lucky Phil replied to Blueboarhound's topic in Meetings, Clubs & Events

lovely image. Ciao -

Just be aware that depending on the model RAM clutch you have the plate thickness might require to be different. You can use the later thicker plates on the earlier clutch but you need to modify. open the small image under the main one and it gives you the diagram and requirements. http://www.mgcycle.com/index.php?main_page=product_info&cPath=193&products_id=3117 Ciao

-

From the album: lucky phils V11

-

Nice work. I love this kind of thing, both the engineering and the added knowledge base. Ciao

-

I'm assuming that the stator housing is probably cracked as I see no other reason for the bodge job with the clamps and resin. There is no rattle issues normally Ciao

-

Buy yourself a new alternator stator housing, believe me its the best option. As for the cover mount bolts they will be 6x1 and 30mm sounds right. Dont use SS fasteners. I know they keep their finish better than passive cad plated bolts but SS is a poor choice for any fastener. They were only ever made originally for the boating and construction world where the premium was on corrosion resistance. They simply dont have the elasticity for effective engineering fastening. I use Titanium bolts wherever I can and the std passive cad plated steel where I cant or its too expensive to use Ti. Timesert or helicoil the front engine cover mount holes. Timesert is my prefered option. Do it once and do it right and you wont be sitting on the side of the road sometime wishing you had. Ciao

-

Ive owned a couple of K100's in the past and the gear indicator was one of those things that you don't really need but its nice to have. I generally used it to check I was in top gear. I still toe the lever sometimes to check I'm in 6th when my brain is in neutral Ciao

-

The manual doesn't mention a minimum thickness for friction or steel plates but new plates are 8mm from what i've seen on MG cycles website. So worn out would be be anything under 7.5mm i'd imagine. Ciao

-

If you can, get someone to hold the cylinder down while you pull the head. Ciao

-

Not unless you want the extra work. If you're careful and dont disturb the cylinder while pulling the head you'll be good. Ciao

-

Another surprise. I pulled the old input shaft seal today and noted the input shaft fwd bearing not seated in the casing to the tune of 1.5mm short. You can see the evidence of this in the inner race. Should be fairly easy to rectify. Its not a major issue other than the bearing outer race is not fully supported in the case. Makes you wonder whos putting these things together sometimes. Might be the same guy that lubricates CARC swingarm bearings. He's moved onwards and upwards. That's around 1.5 mm short of the shoulder. Evidence of the bearing not running central on the race. Ciao