-

Posts

5,449 -

Joined

-

Last visited

-

Days Won

276

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Lucky Phil

-

Nut side, not that its going to make much of a difference. Ciao

-

Timing Gear Set - Replacing timing chain

Lucky Phil replied to FalcoLion's topic in Technical Topics

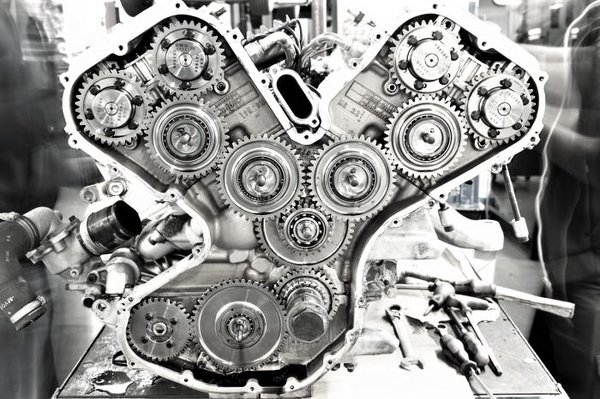

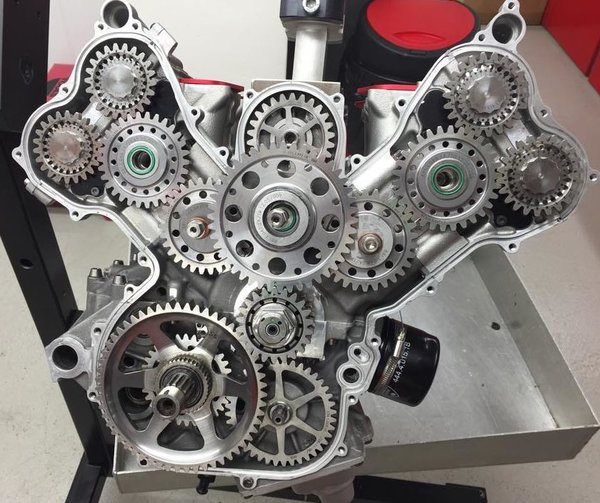

The original pump isn't going to fail but as has been mentioned the pump from Joe is better quality and addresses some issues. Most of the answers you are looking for are in the images. The pressed in steel support for the idler gear means the gear runs on a hardened steel shaft and not a gear supported on an integral shaft running in an alloy housing. The gear is better supported and the housing wear is eliminated as shown in the images. Some of the internal housing wear can be due to the minimal support of the original gear and a combination of wear between the shaft and the housing bore allowing the gear teeth faces to contact the housing internally causing damage which reduces oil pressure. Having the shaft rotate in the housing also means you lose oil pressure through the clearance between the shaft and the housing bore. Joes pump will last longer than the std pump and will pump slightly more oil due to less losses. Joes pump I believe also uses the later Daytona/Centauro/MGS-01 21mm wide pump gears as apposed to the 16mm V11 gears which means it has the highest volume oil pump of all the big block engines. So better, quality, higher volume, less losses and better durability probably sums it. I guess at the end of the day most people fall into 2 camps, those that think quality has value for its own sake and those that dont. Its a bit like people that pay big money for a beautiful original looking custom paint job without any orange peel etc. It has no practical value and is going to cop damage etc from road use but they still want and appreciate the quality. Individual value systems. Ciao -

Timing Gear Set - Replacing timing chain

Lucky Phil replied to FalcoLion's topic in Technical Topics

No I fitted the gears to my old pump but Joes new version is far superior to anything else out there I believe. His pump has the idler gear running on a steel shaft like a Ducati pump instead of the shaft being incorporated in the gear and it running in the alloy pump housing. The whole upgrade is about quality improvements as Mikko outlined and that's exactly how I feel about most mods I undertake. Its an opportunity to correct the cost cutting and quality short cuts of a mass produced piece of engineering. It will never equal a factory race bike of course but its an interesting and satisfying engineering path to go down all the same. Of course you could always start with something truly horrid in design and engineering terms like a Norton Commando or a Triumph twin but lets face it nobody wants to waste that much time:) Ciao -

Timing Gear Set - Replacing timing chain

Lucky Phil replied to FalcoLion's topic in Technical Topics

I covered this in my Joe Caruso timing gear install thread. Dont bother checking it just fit a new one. Tip....you can buy the old version much cheaper than the updated version and simply die grind the oil feed slots yourself in about 5 minutes. Ciao -

I think the days of gears were over once accountants and not engineers started running businesses. Ciao

-

From the album: lucky phils V11

-

From the album: lucky phils V11

-

The noise from gear drives varies depending on many factors including engine harmonics but also mesh clearance cold and hot. I've had engines that wine when cold and have a slight clatter when hot. As the alloy crankcases heat up and the bearing centers that support the gears move away from each other the whine caused by tight clearances dissipates and is replaced by gear backlash noise. depending on many many variables is the volume of noise in hot and cold conditions. I was in the pits back in 1988 at Oran park round of the WSB talking to Robert Dunlop who was riding a Honda RC30 that year as a privateer and hung around to hear it start up before the first race. That was the first time I'd heard an RC30 with the backlash gears removed and it was quite noticeable. Although Honda would have run a decent amount of tooth clearance and relied on the backlash gears a fair amount as it was a production engine system. I owned an RC30 at the time so was interested in what modifications he was running in WSB. The list of engines that have used cam gear drives is like a who's who of brilliant engineering. Manx Norton, bevel drive Ducati, Guzzi V8, ahem...the Guzzi big block V twin and of course the venerable Rolls Royce Merlin. If anyone needs any more convincing after reading that list I cant help you Hears some engineering art to ponder. Ducati Desmosedici V4RR Ferrari V12 Ciao

-

The Daytona I've just assembled and just about every engine I've worked on over the years including Ducati race engines has used round section wire retainers. Button retainers that I've seen were generally used on drag racing engines. Ciao

-

Looks fine docc. Fit up the new stuff as you said. Ciao

-

Grind or rat tail file some notches on one end of the new one docc so you can get a narrow ended drift on the inner race. Even with the collars you can usually get enough radial movement on the spacer to help get the drift on the inner race. After you install one of the bearings drop the spacer in and check how it levels up with the bore end face on the other side. Remember the bearing will have a little lateral play to take into consideration. Ciao

-

I'd keep the the collars as you have found the spacer drops down and axle fitment is a pain. Some spacers have a notch ground on the face of one end so you can get a drift down the bore from the opposite end and get some purchase on the inner race for removal. I forget if the Guzzi has this or not but when I have them out I always grind another notch opposite the original if it has one or grind 2 notches for ease of bearing removal in the future. My rear spacer had a collar standard. Some spacers only have 1 collar and you can then lever the spacer over a little on the non collar end and get a better purchase on the inner race for drifting as well. Ciao

-

The collars on the spacer? Ciao

-

Oh, ok docc, I skimmed through the original posts again but missed the only 600 mile life. That's very bad indeed. Its always a worry when something unexplained like this happens. All you can do is assemble it all with the best engineering practice you can and monitor the results this time. Cant see why it shouldn't work out better than the original bearings with the correct spacer. If you are really keen you can flip out the seals from the failed bearings and wash out any lubricant and debris and use a magnifying glass and look at the races and see where on the races the wear and failure point is. Is it central to the race which would indicated the bearing has been overloaded or too tight in the bore or lacked lubrication or if the wear and failure indications is a little offset which would indicate lateral overloading from a short spacer. Ciao

-

Noise from cam gears is not really an issue. Honda V4's like my old RC30 and VFR750 had gear driven cams and met noise regs for road bikes. They incorporated backlash gears with the cam drive gears to help them run quieter. Ducati Desmosedici's are gear driven cams and are noise compliant road bikes. Lots of engines use a gear and chain hybrid drive for the cams these days. The Caruso gears in the V11 run very quiet. I can hear them but thats because I'm listening for them otherwise I wouldnt be able to tell them from the chain driven cam. Ciao

-

Yes 8 X 1mm thread. Torque, 2-2.2 kgm with loctite 601. Ciao

-

Didn't you ascertain docc the spacer was 0.045" too short docc? If that's the case there's your prime reason. Ciao

-

Taking off the transmission cover wont get you access to the clutch push rod. Did you reinstall the clutch push rod button in the clutch when you re assembled it? If you mean the slave cylinder securing screw head is chewed out then you really should fix that by drilling the head off and then removing the other 2 screws ,pulling the slave cylinder and then extracting the remaining stud. If its the thread stripped then you can remove the slave and timesert or helicoil it. Either way you should really do it. It just requires swing arm removal for access which is fairly easy. Ciao

-

The pickup tube thats part of the whole lube assy enters the screen unit from a hole in the top.The filter unit itself is bolted to the sump floor. Its there to stop any particles larger than around 1/4mm from entering the pump. I fitted a new one to my Daytona engine during the rebuild as a precaution. Not the sort of thing you need to worry about very much. I wouldnt do a sump drop just to check its clean but if you have it off take a look. Ciao

-

Both of my bevel boxes have radial play. I don't like it but it doesn't seem to be an issue. It's also easy to mistake play in the outer bearing with wear in the small inner. There is a technique to distinguish the two I posted a few years ago. you can't really use the lock ring to eliminate the play either by tightening. I found when my rear wheel bearing badly worn I had a clatter feel through the footpeg with the throttle in a float setting. Power on and in the overrun was ok. ciao