-

Posts

5,449 -

Joined

-

Last visited

-

Days Won

276

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Lucky Phil

-

Yes all Hi Cam powered bikes. For the sake of accuracy I did a quick re check and the number I came up with on the web was 3174 but I'm sure Paul Minnaert and I have discussed this and the number was 3910 which stuck in my admittedly none to accurate memory. Anyway you get the idea, not many in the grander scheme of things. If Paul chimes in I'll modify this thread so nobodies mislead in the future. Ciao

-

Old post I know but 3910 High Cam bikes were made total. Ciao

-

Will very generously sent me the std Centy and Daytona RS .bin files for free so I could look at the std mapping . Others wanted to charge me for this 25 year old commercially redundant information. He didn't send me information on his customised chips and I wouldn't pass on that info if he had as he still sells these and it's his intellectual property. I also was generously provided with a couple of modified .bin files from a member on the German forum, Karsten. Both of these work quite well in my 15M controlled engine and were a very good base to start from for mapping my particular engine. having the base and modified map details was an enormous help reference wise. Using a 15M ecu on a Centy or Daytona that you can readily programme with guzzidiag and tunerpro is eminently doable as I have proved. Check out my V11/ Daytona build thread for some details. Ciao

-

Yep Ciao

-

The std connection one. Maybe the ESR515, not sure now. bought about 6 years ago. Ciao

-

The ECU I believe. It has an unswitched hot wire to it through fuse 1. Ciao

-

From the album: lucky phils V11

-

ANSWERED Neutral switch stays on after assembling shift plate

Lucky Phil replied to MartyNZ's topic in Technical Topics

Yes docc there's an issue there. The gears should sit flush. Like this. I magnified this image on my computer and they are def flush as I remembered them to be. Ciao -

Well riding style and conditions have an effect of course but the cold start cycles are something I think people aren't necessarily aware of. The amount of fuel that gets thrown at the engine getting it up to temp esp in cold weather has a big impact on the range. I got caught out 20 years ago on my Aprilia RSV1000 when it ran dry about 20klm before usual and it was lucky to get 270klm out of a full tank of country riding so was marginal on fuel range as it was. I'd filled it up after the previous ride but then did 4 or 5 cold start cycles with little mileage and it caught me out on the next weekend ride. Always best to fill up at the start of the ride with a warm engine on the edge of the city for maximum range. The difference is very noticeable. Ciao

-

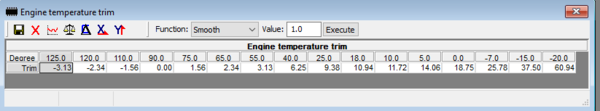

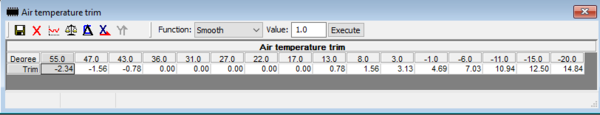

I think I've mentioned this before but what makes a surprising difference to fuel range is cold start cycles. So you may fill your tank and then do 4 short, say 10 mile round trips to work for instance, look at you trip and think, yep still got 120 miles of fuel.....nope, no where near it. It's a way greater effect than a single 40 mile urban commute. Obviously suburban riding hurts the economy but it's the cold start cycles that have the biggest effect. If you add the start enrichment map and the engine temp trim map figures together the overall fuel metering can be well over double the delivery at running temp fuel mapping. Ciao

-

My bike has a new electrosport and I think from memory it puts out around the same voltage amybe a touch more on my multimetre . I've tried to think of a way to calibrate a multimetre as well but haven't figured a reliable voltage source to use a reference. I guess the best way to decide if the battery is charging adequately is to go for a suburban ride for say 30 min with the lights on. Park the bike for an hour and check the battery voltage. 12.85 volts or better means the charging system is fine. Be aware though that the V11 does have parasitic drain of around .070 volts so the battery will drain over a period. Ciao

-

The intensity varies on mine, not that it means much really. The last thing I'm about to rely on with an Italian motorcycle that's 20 years old is the fuel warning light and the Neutral light. The trip meter is my guide. Then again I've twice rolled into petrol stations coughing on fumes. Which either supports my theory to the perfection of my range calculating or not, depending on your perspective. One thing I never do is let an Italian motorcycle warm up on the side stand with the neutral light illuminated. That's just too tempting for the Italian God of electrics. Ciao

-

Straight off a charger or immediately post shutdown an Odyssey will read well above 13 volts for a while until the surface charge dissipates but from memory 12.85 is fully charged after that. As a matter of fact 12.5 volts is only around 40% charged for an Odyssey. The figures are on their website. Ciao

-

Not surprised with 230 kg dry weight and 80 WHP on a 170/180 section rear tyre Ciao

-

Screenshot 2021-07-23 085537.png

Lucky Phil commented on Lucky Phil's gallery image in Members Gallery

-

From the album: lucky phils V11

-

From the album: lucky phils V11

-

When I rebuilt the Centy engine Chuck I had the option of the plastic or the brass temp sensor holder, I went with the brass. I can't remember which was the later version but read somewhere recently it was the plastic which wouldn't make sense to me as i would always go with the later updated part when I have a choice. Anyway part of my logic at the time I do remember was the plastic holder seemed to have the sensor bulb suspended in mid air within the holder which didn't seem like a good idea with regards to responsiveness so I went with the brass holder and also applied some high temp grease inside to surround the sensor bulb and transmit heat from the holder to the bulb more directly. Did it work? not sure as I have no comparative data but it runs nicely Ciao

-

The Cam chain is actually in a power transmission path, the path to transmit force or power if you like from the crank to the load, which in this case is the valve train. That load varies with rpm. The tension on the cam chain is related to the load it's being asked to transmit. More rpm requires more energy to drive the valve train so the load on the cam chain/drive is greater. Also F=ma so Force = mass x acceleration so the valve train and cam drive all have mass. The faster you accelerate that mass the more force is required and the cam drive needs to transmit. So it follows that the more rpm the engine is turning and the rate at which it gets there increases the load or force on the cam chain. At steady state throttle opening and engine load the force on the cam drive is constant. Ciao

-

ANSWERED Installed new battery, spins over but won’t start

Lucky Phil replied to Taxguy's topic in Technical Topics

Yep, it's a skill getting all those wires on the bolt including the battery tender wire and threaded onto the terminal. Imagine casting aspersions on Italian electrics! Ciao -

ANSWERED Installed new battery, spins over but won’t start

Lucky Phil replied to Taxguy's topic in Technical Topics

Or maybe, just maybe, you missed connecting one of the hot side battery wires. Like the one that powers the ECU through fuses F1 and 2. Ciao -

So do I, Aviation, but I trust my own engineering. I wouldn't do anything unless it was safe. Belt and braces for me. You know 20 years ago we needed a "special tool" to remove a component in the lube unit of the CFM-56 jet engines that powered the Boeing 737's in our fleet. We didn't have the tool and the lead time to get one was long and the Maintenance Manual showed a drawing and dimensions. So I requisitioned some material out of the stores system and took it home and machined/made a couple and took them to the tool crib for use doing the job. All worked perfectly for maybe 5 years then the Aviation world went totally compliance crazy. It was always quite strict but then it went totally full scale. My terrific and perfectly useful tools went in the bin. No official paperwork to certify their "compliance" sigh. Ciao

-

Yes I'm aware of the this and it's all largely correct, the valve spring returns SOME of its potential energy back to the camshaft after it's compressed but it's a matter or proportion. From memory it can only return around 80% or maybe less on average due to friction, and other dynamic losses such as having the task of reversing the valves acceleration and pulling the valve back onto its seat so the net result is still not a reversal it's only a lessening of torque in the same direction. There is no perpetual motion machine you don't get all the energy back at any point so the net result is always an input to a greater or lesser degree which keeps the force in one direction to a greater or lesser degree. A multi valve/cylinder engine with more lobes smooths this sine wave energy action as does greater rpm. If it was some sort of single cam lobe mechanism with little or no frictional losses and little work to do I might be convinced but for a typical engine running in typical circumstances I don't think so. I think I dispelled the theory of the cam drive and wear/play and inadequacies/wear/spring fatigue in the tensioner causing the hiccupping when I went to the gear driven cams. It made no difference at all I'm disappointed to say, it still hiccupped as before in the same particular circumstances. Ciao