-

Posts

5,449 -

Joined

-

Last visited

-

Days Won

276

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Lucky Phil

-

You might be very surprised at the lack of science put into the mapping and how loose the process is. One particular late model Guzzi when you look into the software it's obvious they started with a Ducati map because it's notated in the ID details. They didn't even bother to change it as only people digging deep into the software would find it. So you go to WM and want a map for your latest model and they just dig out maps from another customer with a similar engine design and capacity and start there. Fair enough but you do wonder sometimes how interested they really get in making it run really nicely. I also had a couple of Triumphs T595's back in the late 90's and they ran the French Sagem system. The factory released plenty of software updates to correct things like random stalling when stopping at the lights and other stuff. I thought it must be terribly hard to rectify this stuff then my friend installed a Motec unit on a customers bike and had the Triumph running and carburetting absolutely perfectly after about 30 min on the dyno. So an injection system manufacturer and a motorcycle manufacturer couldn't do what a talented guy in his own business could achieve in 30min. Sometimes the big wheels turn so slowly they just grind to a stop. Ciao

-

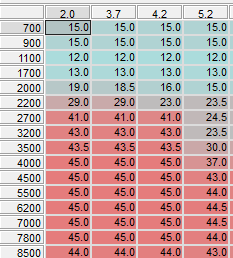

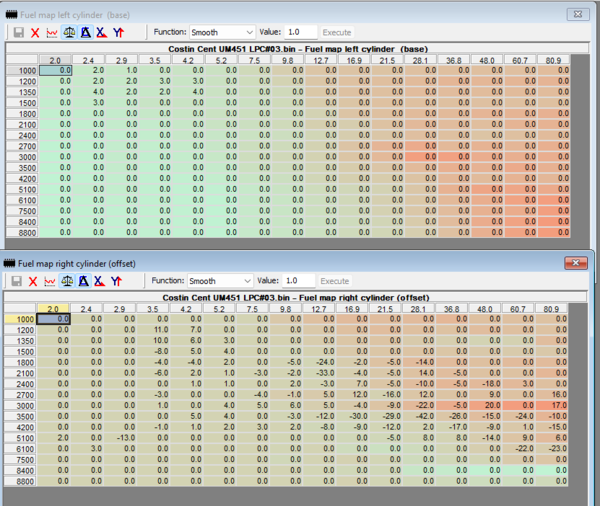

I just went and looked at a std v11 2000 fuel and ignition maps and one interesting thing is around that RPM and probable throttle opening there is a large step in the ignition advance. So 2700-3200 rpm and 4.2-5.2 deg throttle which is kind of in the area of issue. The advance change is interpolated between these cells of course and maybe I'm wrong but possibly this area of change combined with engine temp and OAT play a part. If I still had the 2 valve fitted I could have a play but of course when you want it to hickup it never does. Ciao

-

From the album: lucky phils V11

-

It's a question that has been around as long as the bike and experience by many including myself. I don't know of anyone having an answer to it. Some suggested wear in the cam chain affecting the ignition pickup but mine still did it after I upgraded to gears. My experience is the same as your and it appears to come and go with changes in OAT. If I still had the 2 valve engine in the bike I would be experimenting with fuel mapping via Tunerpro in the affected area and the engine temp break point maybe. The Daytona engine doesn't have the issue. Ciao

-

I'm in discussions with Joe now on the design of a new oil pump along with Dynotec and I'd suggest anyone interested in new gears in the future get a group together now and get him do a run. His Gear maker isn't getting any younger and it's a bit of a labour of love as well so the availability of these things won't necessarily stretch into the long term horizon. I've got another set of Daytona gears coming at the end of the year for a 95mm bore engine I want to build as well as the new design oil pump. Don't want to sound too pessimistic but recent circumstances have focused me on the utility of acting sooner on things rather than later. Ciao

-

Le Mans handlebar end weight: powder coated or standard paint spray?

Lucky Phil replied to p6x's topic in Technical Topics

The originals look to be "blued" to me, same as the finish on a gun but polished first. You can buy bluing kits and do it at home as I did with the frame side plate bolts and a marking out tool I restored in a thread here somewhere. Ciao -

You could replace the big and bulky rear drive torque arm with an aftermarket unit with rod end fittings which would give you a lot more room to play with the vent solutions. Your oil deflector of some sort seems like a good idea. Ciao

-

-

Yes mine doesn't have that now. I spaced the regulator up a few extra mm so the vent hose now runs under it and has a straight shot at the airbox. You can just see it in this image passing under the regulator and fuel filter. Ciao

-

I just used 8mm EFI hose on mine. Even plain rubber hose is fine, it carries no pressure, it's just a vent hose. Same for the big hose from the crankcase breather. They seem to last about 5 years or so before they start to perish. They are in a hot environment. Ciao

-

Whatever happened to the "right price" being "whoever drags it out of my sight and doesn't charge me to do so". Seems to me what it's worth in the harsh light of day. Maybe a case of beer, cheap beer that is. Valuing old shitters like this is about what you want it to be. A part it out exercise, full resto, old rat bike, what? and of course the hidden mysteries within. Ciao

-

Pull the inlet trumpets out and get your hand or a rag on a stick in there and give it a good clean out. Ciao

-

To Cap( the fuel regulator) ... or not?

Lucky Phil replied to Tom in Virginia's topic in Technical Topics

Under no circumstances cap that port off. The fuel map is designed to meter fuel at a pressure dictated by the regulator which controls that pressure via a bladder with spring pressure on one side and atmospheric pressure on the other. Plugging the vent will seal the bladder from atmospheric pressure and affect the delivery pressure. It was originally used on other applications to regulate fuel pressure to inlet pressure but everyone abandoned the idea early in the piece. The very first injected ducati 851's used it but then discarded the connection. Ciao -

A little bit of simple green or C18 truck wash. you dont need much around 3% is enough. I used petrol with some injector cleaner to clean the injectors in my small jewellery ultrasonic bath. I also had it connected up to a 6volt battery supply to hold the injector open while it was cleaning. It was such a dodgy thing to do (outside in the full open air I might add) I stood by with a fire extinguisher the whole time. I was thinking as it was working that this is the sort of practice that ends up on the nightly news. I'm making a home made safe injector cleaner now. Ciao

-

After recently rebuilding 3 throttle body sets I use one of these. I've 2 one large 20Litre one and a small one for, well small stuff. Forget the toxic spray and soak junk these work perfectly esp for things like throttle bodies. https://www.amazon.com.au/Ultrasonic-Cleaner-Digital-Durable-Stainless/dp/B08R73QMYR/ref=asc_df_B08R73QMYR/?tag=googleshopdsk-22&linkCode=df0&hvadid=463522662873&hvpos=&hvnetw=g&hvrand=803062948571161468&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9071372&hvtargid=pla-1161471464591&psc=1 Here's what a 25 year old second hand covered in grunge throttle body looks like after 30min in the ultrasonic tank. Plus all the internal passages are clean as well. Ciao

-

I wouldn't recommend that personally. Unless there is debris clogging something all you do is loosen up stuff you don't want to. The drain line is via a banjo fitting anyway so it's a horizontal inlet the the pipe so contaminants don't tend to enter unless there's a LOT of stuff, usually rusty stuff in the spine. Ciao

-

Not surprised it has some running issues. Ciao

-

Nothing works perfectly docc it's a pretty crude system so some oil vapour still gets in the airbox and condenses over long periods of time. Who here periodically gets in and wipes out the airbox interior? Ciao

-

Thats my suspicion docc. The breather into the airbox is also on the Left hand side as well. Ciao