Leaderboard

Popular Content

Showing content with the highest reputation on 11/07/2022 in all areas

-

Please note the various nicks and cuts on his hands from previous attempts 😉3 points

-

I found the video on youtube that I mentioned above, copied in a link below. I don't bother with releasing the fuel pressure first like he does, I just wrap the whole works in a rag to catch any fuel. Thousands of guzzzi owners are indebted to this video poster for solving one of life's greatest mysteries.3 points

-

Hey @stewgnu Thank you so much for taking the time to do such a great job on this schematic,especially the excellent color detail. I was working on my bike getting ready to dive into a possible, relay/wiring nightmare, and I have a severe aversion to electrickery. I had misidentified all my relay locations and couldn't understand why my wiring colors, didn't match your schematic,figured it was just an Italian glitch. But I looked at your schematic long enough to properly identify the relays and confirm that everything was in order,no need to break out the wrenches and dive in any further. Extreme gratitude, very well done Sir3 points

-

Its a bitch...especially if it hasn't been apart for a while and wasn't lubed the last time it was apart..if ever..make sure your system is de pressurized . lots of care..I got rid of mine and put a gates hose on the red fitting and a metal quick disconnect from AF1 in the line ..3 points

-

2 points

-

2 points

-

First flush and bleed the system thoroughly with new fluid. All the way. If the fluid in it is old, this will make a difference.1 point

-

I'd try fitting the left pivot pin from the inside, so that the pin swages the damaged outer few threads into line. After that, wind that LH pin out enough to fit the swingarm and RH pin. If you use a tap to recut the threads, you risk having a loose pin if you don't use the correct tolerance tap.1 point

-

1 point

-

Hello everyone, While installing the pivot pins I have accidentally cross threaded the left one. In my opinion it’s nothing major, only the first two threads are affected however it is enough to prevent the pivot pin to line up and to easily screw in. (please see the pictures included, the damaged thread is at about 6 o’clock in the very entry to the hole) I am thinking about rethreading the pivot hole from the inside with a relevant threading bit. Does anyone have experience with repairing the swing arm pork chop pivot holes? I am assuming it’s M22x1 of metric fine thread – but I will gauge it properly of course. I am expecting to screw in the threading bit from the inside, where the threads are ok. This way the threading bit will line up with the existing threads and it will probably go thru easily for about 95% of the hole length. Only then it will hit the damaged threads and cut thru them. So much for the theory 😊 Anybody attempted to rethread these swing arm pivot holes? Thanks for your advice/opinion.1 point

-

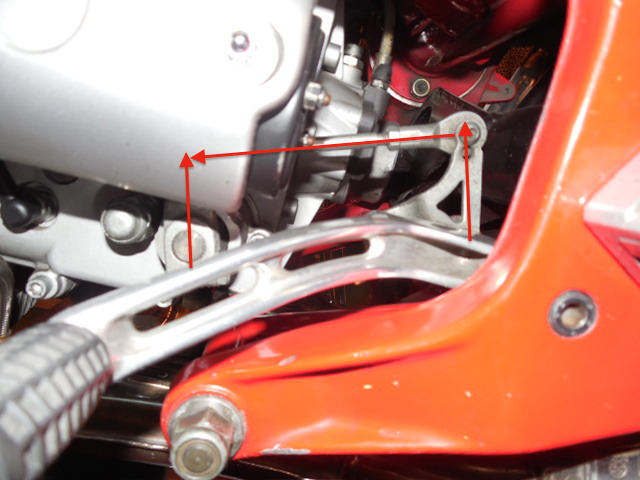

I finally installed my shift extender, makes a difference, improves shifting for sure. I still have to dial it in though, I'm not sure which way, extend or shorten the throw rod.1 point

-

1 point

-

1 point

-

Hey Docc, After studying Stewgnu's schematic, I realize that my relays and the wiring connections appear to all be in order. The guzzidiag connection issue might be one of those unsolved mysteries, lol1 point

-

Seems your V11 runs right. GuzziDiag connectivity is a mystery to me.1 point

-

The 2002-on change to relay function involves shifting the starting demands to the Ignition switch instead of the #1/Start Relay. The middle/#3 "Sidestand Relay" (that is pulled in by the Neutral Switch NOT the Sidestand Switch) remains unchanged throughout the range. Of my three questions, you only answered #1 . . .1 point

-

It's a funky finesse feel kind of thing,that will drive you crazy until you learn it. DON'T go near it with any type of tool,it's crappy brittle plastic,just waiting to break and fall apart. The first time I did the quick disconnect on my CalVin,I danced around it for days,with a variety of tools,very lucky I didn't break anything. The turning point for me was watching a youtube video by a Norge? owner,his first video of the technique was so well received he posted a 2nd one with a closer camera angle,do a search for it,if you're lucky you'll find it. Iirc the motion on the V11 is opposite from the CalVin, but the theory is the same, while supporting the plastic elbow with your left hand so it doesn't break, push or pull the collar just slightly to release the mechanism internally,while keeping that pressure on the collar,just wiggle it gently back/forth slightly and pull the whole thing off. It's instinctive to me now,I can do it with my eyes closed,but until I learned that feel, pull/push/release pressure/wiggle/off,,, I was ready to torch the bike.lol. Hint, don't do it when you're frustrated,come back at it with fresh eyes and patience. A slight spray of WD40 on reassembly helps prevent issues in the future. fwiw ymmv good luck1 point

-

IDK if there is a tool available for this connection . IFIRC , you push the hose in then push the collar back to the hose and move everything away from the fitting . You may have to twist the collar while pushing the fitting off the line. Once you master this , do it a few times and get familiar with the procedure and try to remember it.1 point

-

(snapping suspenders, tamping corncob pipe) Back in the day, our local EAA chapter used to get a night per year at the Dayton Air Force museum. It was after hours, and we could get in anything we wanted, wiggle the controls, yell, CLEAR! etc. I'm not much of a warbird guy.. but it was a hoot. Most of the fighters reminded me of the old adage.. an elephant is a mouse designed by the military. Except the Spit. The cockpit is just right. Everything falls readily to hand, as they say. Good visibility from the cockpit, comfortable. That is one warbird I'd give a go. The wierdest? The ME262. Those Germans.. who else would have rudder pedals that go up and down?1 point

-

Never have so few dollars given so much shift joy to so many. Chuck deserves some major thanks.1 point

-

1 point

-

On my '97 5-speed, I had so much trouble getting to the nipple and modifying grease hose ends I just take the dang wheel out and grease the splines by hand while I'm at it. There's a hole in the swingarm above the zerk, but it's difficult access at best.0 points