All Activity

- Past hour

-

Heh, "Sportona". . .

-

Inventory of and creating a Moto Guzzi V11 Scura owners list

Pressureangle replied to Danny-NL's topic in 24/7 V11

Even more to the point then, it seems you're quite proud of it, despite being a mongrel. Or perhaps *because* it's a mongrel. Why is it different, how you feel about yours, and why, and for others about their own? -

Inventory of and creating a Moto Guzzi V11 Scura owners list

Lucky Phil replied to Danny-NL's topic in 24/7 V11

I think you have me confused with someone else. I don't own a Daytona I own a mishmash bike that started as a Greenie and now has zero value to anyone even vaguely interested in originality or "numbers" A particular motorcycle brand has no particular emotional connection to me other than a technical interest and the obscure idea that I happen to like that piece of machinery. They are machines and thats it basically. I like some more than others. They have no real "meaning" in my life, just a way to express my engineering interest. Nothing more. Phil -

#608 added to the Scura Registry! This reminds me of a John Ruskin quote, "The highest reward for a man's toil is not what he gets for it, but what he becomes by it."

-

Inventory of and creating a Moto Guzzi V11 Scura owners list

Pressureangle replied to Danny-NL's topic in 24/7 V11

Says the Daytona owner Lemme remember some of gramma's platitudes 'Don't put taste in someone else's mouth' 'One man's trash is another's treasure' The value in a Scura, a 1100 Sport, or a Daytona was never measured in money, but in the owner's life. That has never wavered. Owning and riding MG, particularly older ones, lets a person know that even if you can't see it directly you share something deeper than Thursday night HOG club meetings. - Today

-

Inventory of and creating a Moto Guzzi V11 Scura owners list

Lucky Phil replied to Danny-NL's topic in 24/7 V11

Thats why all this limited edition stuff isn't worth JS. To start with it's done by Italian manufacturers and esp back then they were pretty loose with their management of these sort of things and secondly the majority of the "specialness" was just cosmetic or things easy to add/update at a later time if the owner wanted to. Some exceptions exist like Ducati 1098R models which had sand cast crankcases and Ti rods in addition to the Ohlins suspension and carbon but mostly it's just a vaguely managed marketing exercise for people that get themselves convinced they have something "special/unique". Lose the numbered plate which has happened many times and it's never replaceable or even orderable and there go's your "special bike". It's just a modified stocker now. I bought a Monaro CV8-Z 20 odd years ago that was a run of the "last of the Monaro's" limited to 1600 units which turned out so popular that after I took delivery of mine they decided to release another batch of 1400. Lucky for me I was going to buy one anyway and didn't jump on some bandwagon but as I said the special edition stuff is a "come in spinner" situation mostly. -

David Konings started following best place to get red valve covers & matte grey frame plates?

-

Sam P started following Speedometer Help Again

-

Inventory of and creating a Moto Guzzi V11 Scura owners list

David Konings replied to Danny-NL's topic in 24/7 V11

Hi Danny, I’m Scura #608, located in the south-east of the Netherlands Regards David Verzonden vanaf mijn iPhone met Tapatalk -

David Konings started following Inventory of and creating a Moto Guzzi V11 Scura owners list

-

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

Where the heck did you find that? But yay! I missed the iron butt, due to the well-known but ill-considered shortage on BMW GS odometers, and my reluctance to ride at night. A few minutes short, sadly. Did get a free entry next year for siccing the owner of the Studio coffee shop in Wheeler onto David...Sponsored stop 2026. May be more as well, the chair of an organization of 29 Northern Texas Counties happened in while we were talking and was very excited. BTW the 'Tincinerator' is my fav stop pic too lol -

Motorcycle Grand Tour of Texas, 2025 edition.

PJPR01 replied to p6x's topic in Meetings, Clubs & Events

-

Seat is in like-new condition. It has a heater and wiring kit (never installed) and a backrest for the passenger, which was never used, because it didn't fit with the top case. I paid over $1,000 for the custom seat in March 2024. Traded the bike with the stock seat for a new Stelvio, which is the reason I am selling the Corbin. It was super comfortable and seemed a bit lower than the stock seat. Asking $500 plus shipping if required. I still have the original box and packing material from Corbin.

-

- 1

-

-

Sam P started following Speedometer Help and speedo needle wobble

-

Good. One time we had to install some sensors on the Bell housing and set the air gap to XXX . We got the flywheel tooth to the center of the bore , and figured the air gap with the revolution of the sensor threads and bottomed the sensor against the tooth and backed it out accordingly to get the proper air gap.

-

Yes. The safety margin is that, as I wrote, the bolt wont fit between two teeth, and I also ground off the end of the bolt so it is dead flat, no taper in to the thread. So even if just the very edge of the bolt is on top of a tooth, it should still take a good measurement. But that is just the safety margin. I made sure that a tooth was in the middle, and am quite sure my bolt was hitting it squarely.

-

I think we are talking about the same thing......You are making sure one tooth is in the center of the bore where the sensor goes ?

-

Yes, hot water should work as well, and leave no trace.

- Yesterday

-

I didn't worry about TDC, but did have a look at where the teeth on the wheel were, i.e. a tooth there where the bolt in the tool was landing. On top of that, I had a good look at whether the M5 bolt that I was using in "my" tool to measure the distance would fit in between two teeth on the the wheel. It wont. I took a measurement, and went in with the vernier caliper to check plausibility. Then put the bike in 2nd gear and bumped the motor a bit. Took another measurement, and came up with the same result. I'm pretty sure that the measurement is solid.

-

I assume you got one tooth at TDC in relation to the centerline of the sensor ?

-

Yeah, I think it has a bit of a bulge. I have a replacement, so I will most likely just replace it. Might test it, but the power in the garage is photovoltaic, and doesn't have enough bumps (German word...) to power the hot air blower. Maybe I'll have a look at it at home in the kitchen when the girlfriend is at work.

-

It's hard to see clearly, but it looks like your sensor has a little bit of bulge in the center. When mine failed, it was so bulged there that it was hard to pry out. Consider. I bench tested mine simply by checking resistance while cold, heating it with a heat gun (shop hair dryer) and checking with an IR heat gun. When the sensor got to about 170*F, it opened. Measured ok again when cool a couple times.

-

Indeed. @swooshdave , please keep us posted on what you find.

-

Tom, that is very pretty, but I don't have the machines to make something like that. Fortunately, one of the blokes that shares the garage with me bought a drill press a while back. With that, I can drill holes in bits of metal that go really straight through. The rest of it was done with hand tools. I also liked the idea of a tool that can be screwed on to where the sensor sits. A bit of a fiddle to get it on and off, but security that it is really sitting where the measurement is to be made. Whatever, I'm happy with the result. Others have "better" tools for the job, but mine does it well too.

-

And a square head edt, easy and fast to use. Cheers Tom. Sent fra min SM-S906B via Tapatalk

-

Just wondering if the oil level was really low and you cranked into a turn, you uncovered or partially uncovered the pump suction, leading to a momentary loss of oil pressure. If that was the case then in all probability it would recover pressure once upright or close to upright, explaining the event. If the oil was really low then the Roper Plate would probably do little to prevent this Of course I'd go through the preventitive actions already mentioned by others and me, just to entirely rule out other causes. Good Luck with the checks, be interesting to know what you find. John

-

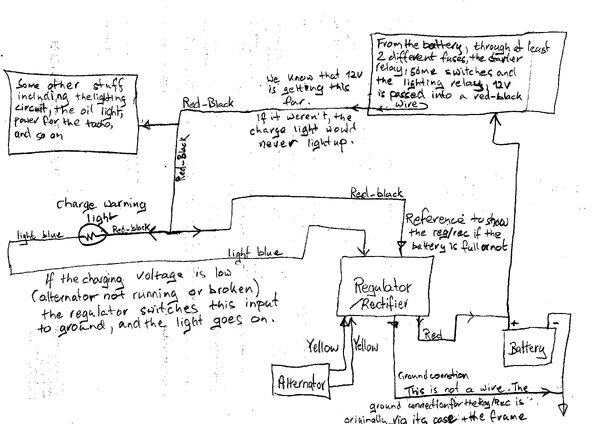

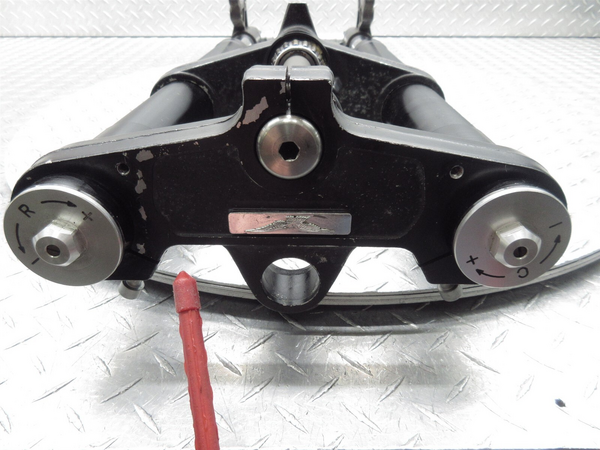

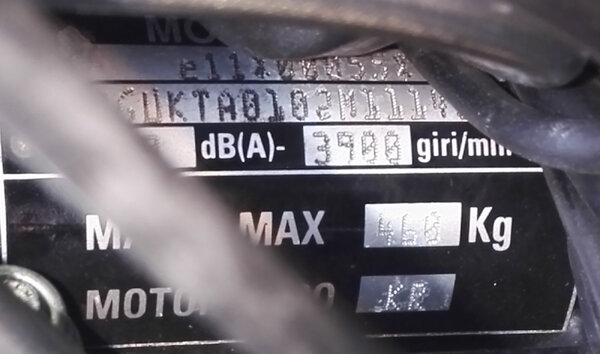

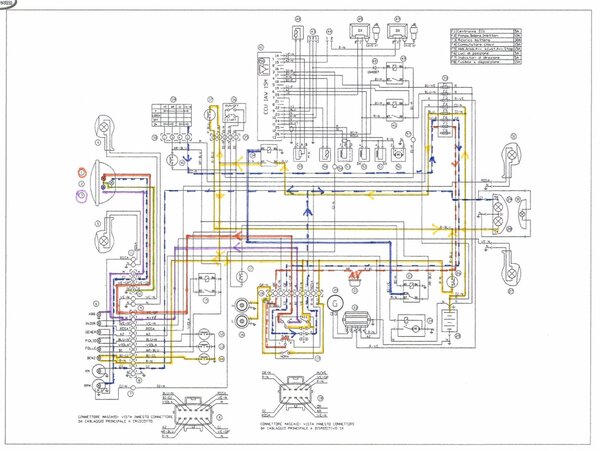

A brief excurse back to the V11: today I made a tool. On the way home it occurred to me that I now know what I wanted to measure, and may well never need the tool again. Still, making it and seeing that the idea worked was satisfying. Anyway, this is it: Using that, and cross-checking for plausibility with the vernier caliper, which can do depth measurements, I was able to establish that the old timing sensor is more or less the same length as the new one, i.e. 30 mm. The distance from the seating surface to the toothed wheel is 29 mm, and the sensor had two 1mm shims fitted. So the gap was 1mm (verified by holding the sensor against the tool and sticking a feeler gauge in between). That is, according to what someone further up quoted from the good book, within spec. Nevertheless, I'll try and get a 0.7mm shim to get it down to around 0.7mm. PS: I was a little disappointed. I had kind of hoped that the sensort would be deformed and the gap far too much. That would have offered an explanation (maybe) for the poor running.

-

That sounds like classic V11 "heat soak" made worse by the ECU always starting up and running a rich map for the first 4,000+ rpm. This effect is exacerbated when the plugs/valve adjustment/state of tune has aged out from the last service interval . . .

![IMG_20241123_224923[1].jpg](https://www.v11lemans.com/gallery/monthly_2024_11/small.IMG_20241123_2249231.jpg.e096b44fe99686a032b551bbf1bb4264.jpg)

![IMG_20241121_231155[1].jpg](https://www.v11lemans.com/gallery/monthly_2024_11/small.IMG_20241121_2311551.jpg.6d864d972198380bf13530b1452c1fe4.jpg)