-

Posts

1,752 -

Joined

-

Last visited

-

Days Won

76

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Pressureangle

-

Spinning on the starter - wont kick over

Pressureangle replied to bentombed's topic in Technical Topics

The ECU tells the fuel pump to run, so it doesn't seem likely that's your trouble, though possible. To check the cam sensor depth, if you have no tools, hold the new and old ones up to each other so the end of each touches the flange of each. They will probably be identical so you can assume the shims that worked in the past will work with the new sensor. The shims are more likely to be dependent on individual case machining than difference in sensor length. Since you're already installed it, if the shims are in, ok. If you installed it without shims, pull to see if the reluctor has shaved the tip of the sensor. The schematic I have shows that the sensor is a simple analog coil, the third wire is in fact a grounded shield to keep AC voltage from messing with other electronics. The wires on the ECU side of the sensor connector should be tan and white, pins 7 and 12 on the ECU connector. With a second helper and a digital multimeter, you can test the sensor at both plugs for AC voltage output while you crank the motor. The coils are powered along with the fuel pump and injectors by the fuel pump relay. Fuel pump primes...Yes? pull an intake boot back, open the throttle and look with a flashlight into the open throttle body. When you first turn the key, or perhaps the run switch, the injectors should spray for a moment, to prime the engine. If you can confirm that you have fuel from the injectors and signal from the cam sensor, then we can look at the magic box. Until then, I'm with Dr. House; "It's never the ECU". -

Is that biscuits and gravy, or SOS? Either way, I'm in.

-

I've only been through there once, in truck and trailer. Seemed like really good riding but I didn't get to see much of it.

-

"...intelligence is innate, not something that someone else has programmed the machine to do." Here's the rub with that. Modern AI isn't programmed by 'someone else'. AI 'programmers' take the equivalent steps to telling your teenager, 'go talk to people and learn from them. I'll provide input and context when you get home." 'programmers' provide training sets, but the heuristics and algorithms assemble the output, not the programmers. What we have today is the functional equivalent of the Ship's Computer in Star Trek.

-

Mmm... I'll not be havin' any lube near my ladder rungs lol Squeaks be damned.

-

Chasing the Bullet

Pressureangle replied to Pressureangle's topic in Special place for banter and conversation

There's something about the dumpy old rusty iron with big flywheels and small carburetors that has an appeal apart from anything more modern. Something everyone recognizes, but nobody can put into words. Something visceral, far beyond nostalgia. As the one man said, "it has to feel like you're riding a machine". -

Now we just need the YouTube link for the 'what are you listening to?' thread.

-

When nothing else will get it apart, Kroil and Time never fails. Absolutely the best penetrating oil anywhere. Use it sparingly.

-

You can order Picker relays from Digikey HERE. I ordered 10, they sent me a rack of 15 at the price of 10. <shrug> accident, or DILLIGAF? Who can say.

-

I thought this a really nice tribute to the Royal Enfield Bullet, and much of the sentiment crosses over all older brands.

-

The thing about California (in particular, nevermind the rest of the West) is that there is *so much more* territory than in the East. I rode the entire PCH, through the Redwoods, back and forth to Lake Tahoe...days on end of fabulous riding. It's a long term plan to spend a month or so riding the Sierra Nevada and Cascade mountain roads.

-

Assuming you mean long-term like 'empty on the shelf for a couple years' I would empty and blow-dry the tank, or air dry in the sun (which you don't have) then throw in a quart of WD40. Splash it around with the cap on to cover all surfaces, and shelve it. Take it down once or twice a year for another slosh to comfort yourself on how long it's taking. When you fill the tank with gas, what WD remains clinging is insignificant.

-

I was of the same mind, until I spent enough time interacting with a few to realize that there is no remaining space where a person of average IQ could tel with certainty that their interaction was not with a real human being of average IQ. That was near the same time when I realized that an average IQ is insufficient for independent survival, and thus the reason why the majority of humanity lives in bug hives. So in it's effect, AI meets all the criteria for Intelligent, if not sentient. The Turing Test does not demand a genius IQ.

-

Now you have to explain the guitar part.

-

I am a Unicorn who was honored to be a SME and trainer to Marines at Camp Bastion (Leatherneck) in 2009. I spent most of my 3 years over there with Army. I was disheartened to find that the Army fell short of the professionalism I expected to see, and humbled to find by how much the USMC exceeded it. I was in the unique position to experience most of the things civilians hear about but can't understand. Semper Fi. Enjoy the evening knowing how special that camaraderie is.

-

Tail of the Dragon isn't the craziest road in the country, it just lends itself to hooliganery better than most, and surrounded by great roads and scenery. The riding is comparable to California but wetter. Craziest road I've ever been on is CA 130 between the Lick observatory and San Jose. Handstanding in neutral to make the turns down, the air full of burned brake smell from the cars, what few dared. More like a hiking trail that got paved. https://www.google.com/maps/search/observatory/@37.3371791,-121.6615309,3558m/data=!3m1!1e3?entry=ttu&g_ep=EgoyMDI1MTEwMi4wIKXMDSoASAFQAw%3D%3D

-

I have a feeling I'll be waiting on paint a lot longer than I want to...we'll see.

-

...aaand the new front tire is flat. Hadn't rolled it around any... thought it was the o-ring at the base of the valve stem but actually turned out to be that the stem itself, these lightweight aluminum marvels of ancient Roman wisdom, had split vertically up the side. Difficult to see, but the bubbles prove. I had a set of 90* valve stems that were too short to fit into the '85 LM rims, but was a nice fit here. Rear rim at next tire change, or first flat.

-

Yeah, it has too much rubber on the tires.

-

Front Brake Reservoir to Master Cylinder Hose

Pressureangle replied to Moto-Oopzzi's topic in Technical Topics

Yes but that came later. -

Regulator/alternator location Sport Naked

Pressureangle replied to skibum69's topic in Technical Topics

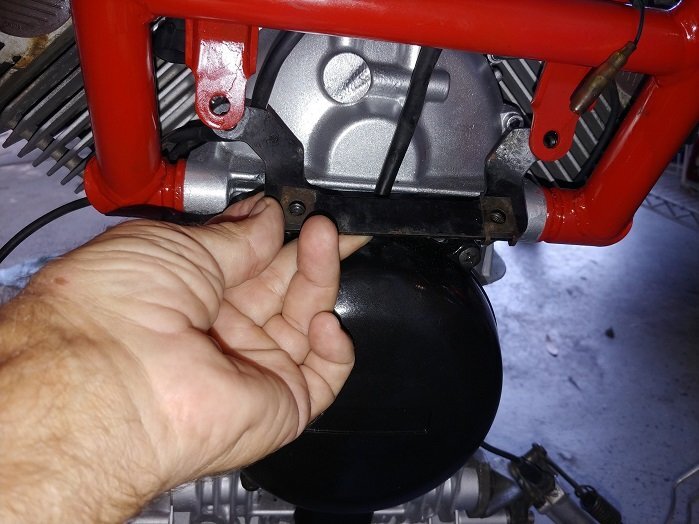

Happens mine is on the bench waiting for new regulator to come. First is assembly, bracket horns regulator Second is bracket placement on frame. Hard to see behind mounted oil cooler. -

Front Brake Reservoir to Master Cylinder Hose

Pressureangle replied to Moto-Oopzzi's topic in Technical Topics

Harumph. Well I'll be in there today, as the front wheel valve stem has a severe leak at the rim. <sigh> should probably do both wheels. I'll ask. -

Front Brake Reservoir to Master Cylinder Hose

Pressureangle replied to Moto-Oopzzi's topic in Technical Topics

Deeper dive with Grok ASTM D2000 Classification system for rubber products in automotive applications, specifying grades, types, classes, and optional tests for physical/chemical properties. Yes Directly relevant; includes automotive rubbers and allows line call-outs for fluid immersion resistance (e.g., via ASTM D471 tests on Reference Fluids like Fuel B or hydraulic oils, which correlate to brake fluids). Automotive seals/gaskets often use D2000 to ensure brake fluid compatibility. The McMaster-Carr EPDM hose has the D2000 rating. I would have to request a full datasheet from McM-C to see if it has the EA-14 callout for glycol resistance, but it is required to claim a D2000 rating. -

Front Brake Reservoir to Master Cylinder Hose

Pressureangle replied to Moto-Oopzzi's topic in Technical Topics

That was my first thought, but a quick search of a half-dozen sources didn't turn any up that wasn't 'specialty hose' at great big prices and I didn't see any 'Brembo' OEM tubing anywhere.