-

Posts

1,752 -

Joined

-

Last visited

-

Days Won

76

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Pressureangle

-

Well there's the crux of it. Music isn't sensible. So we didn't convert to a system that accommodates both Beethoven and Thelonious Monk.

-

Isn't 'metre' a musical measurement?

-

Free to steal. Though 'intermittent Honkiness' came to mind.

-

"30/1000 of an inch, plus or less 10/1000 of an inch"

-

Exactly. The sensor itself is an analog device, sending an alternating current waveform. The AC voltage, at a given RPM, will increase or decrease nearer or farther. The waveform is seen as a simple +/- by the digital electronic device served by the sensor. There is a minimum voltage to trigger the electronics (the measure of which escapes me at the moment) and once they're triggered, they really don't care how much extra is there. If the sensor gets too far away, such as if an ABS sensor gets debris or loose wheel bearings that increase the distance to reluctor, the voltage becomes marginal or intermittent to trigger the electronics so you get...the scientific term is 'intermittent wonkiness' I think.

-

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

-

Well... well. Yes, they induct by the square of the distance. This obviously means they generate the strongest signal set to zero; actually some ABS sensors are set this way, push them in against the reluctor and the bearing clearance pushes them out just enough not to rub. They are designed particularly for this. However, the electronics that the sensor serves are perfectly happy at anything less than about .060" (generally) and .030" guarantees that they won't rub the reluctor and self-destruct.

-

If memory serves, (Bendix factory brakes training) *all* simple coil-type inductive sensors are set at .030" +or- .010". So that's supported by this spec.

-

Well, the oil pressure light...definitely needs investigation. I know you have the means to test the switch, thread it into something and check action with air pressure. If the switch passes the testing, you're into the bottom end somewhere- hopefully just the oil filter loose? My first thought with the sputter stall was 'cam sensor fail'. If it was very hot, such as idling in traffic when it quit, then cooled and rode home in the wind, consider it. Monitor with heat in mind if future similar events. In reality, any failure in about 70% of the connections in the harness could cause this. Relays, ignition switch, run/sidestand/clutch switches, fuel pump connections, battery terminals... My 'Sport was hinkey half the time until I literally swept the entire harness from front to back with DeOxit, cleaned the inside of the ignition switch, added the extra grounds, et al. Now it simply works as intended.

-

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

I am at home, with no plans to ride anywhere on 2 wheels for the forseeable future. Lots to do, and I put it back a few weeks for the tour so BACK TO WORK lol -

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

-

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

Sailed with a few other TourCats the last few days, since on the same route. Good times in the Starlight Theater restaurant in Terlingua. Big Bend area is definitely on my future target list. -

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

Just got home at noonish. Got my paperwork for my 'official' Iron Butt on the horrid I-10/I-75/FL turnpike ride home, motivated me to get it done. Got every stop except the ALT at the 3 corners marker. -

Not yet, they don't.

-

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

I felt poor pulling the Krauser Kluge up next to those Sophia Lorens! -

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

-

ANSWERED Is my Electrosport Stator Defective?

Pressureangle replied to Sam P's topic in Technical Topics

Haven't bread each response, on the road- but *any* wire circuit should show very near zero ohms. If the lamps are in this circuit, maybe ok. If not, a serious fault. -

ANSWERED Is my Electrosport Stator Defective?

Pressureangle replied to Sam P's topic in Technical Topics

Those screws pass through the mounting plate and thread into the plastic housing below (may have brass inserts, don't have it in hand) but you probably feel the plastic housing dropping away, which you can't see. -

ANSWERED Is my Electrosport Stator Defective?

Pressureangle replied to Sam P's topic in Technical Topics

Not so much, really. Unsealed, liquid lead acid needs more float than AGM or VRLA but it's hard even to find those in 12v anymore, usually they're 6v deep cycle. https://batteryuniversity.com/article/bu-214-summary-table-of-lead-based-batteries -

ANSWERED Is my Electrosport Stator Defective?

Pressureangle replied to Sam P's topic in Technical Topics

Pssst. (AGM is still lead-acid) -

lol those things are not mutually exclusive. Lard, FWIW, was traditionally used to lubricate wooden wheel axles. So eating lubricants isn't off the table. No pun intended but I'll take 'em where I find 'em. Maybe that hovering dictatorial moderator will put these posts in a "Tin Foil Hat" thread.

-

History is always fun, funny, and maddening. Lard is good. (From Snopes.com my fav propaganda site) "Crisco wasn’t invented by or for the German Navy, or for the purpose of lubricating submarines. Hydrogenation, the process by which Crisco is made from vegetable oils, was invented by German chemist Wilhelm Normann in 1901. Whether Crisco or similar products were ever used as submarine lubricants remains undetermined." "Wilhelm Normann, eventually sold his patent to Procter & Gamble for use in the food market."

-

ANSWERED Is my Electrosport Stator Defective?

Pressureangle replied to Sam P's topic in Technical Topics

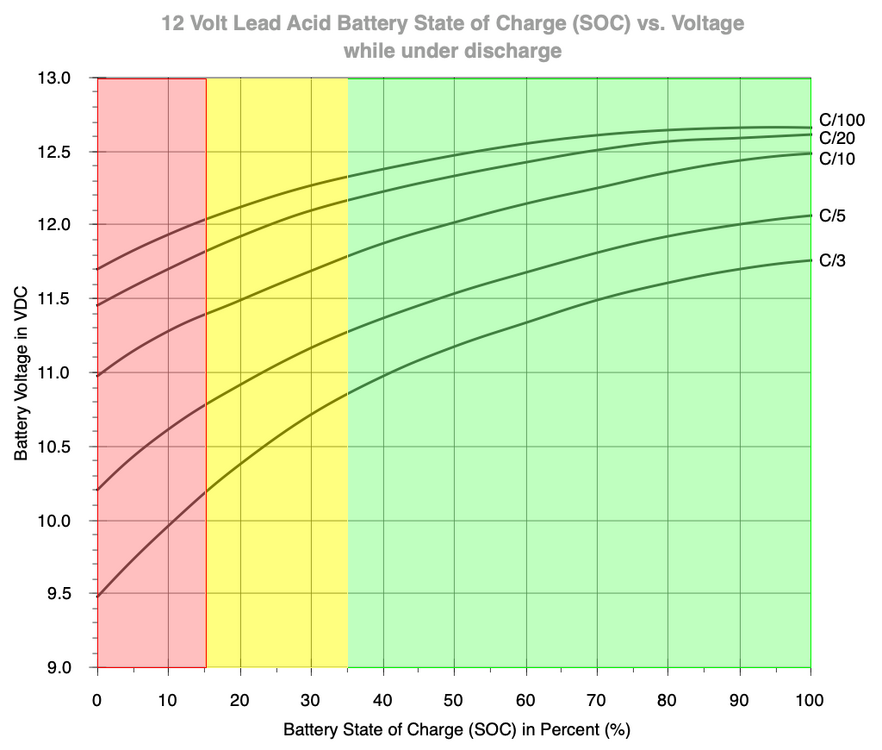

To avoid confusion, here's a chart showing battery state-of-charge; this chart is 'under load', which means the top line would be perhaps 'key on' and the bottom line would be 'starter engaged'. This matters because a battery near the end of it's useful life may show good voltage at rest but fail under load. An at-rest lead battery should be 12.6-12.9 volts unloaded. -

That's actually my first go-to if it's available where I need it. That's in the Bimmer at the moment.

-

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

I'm not the guy who routes in stone, just easy to keep stops in Garmin. How about this; I can start about anywhere, let me know where you are going to be Mon/Tues, maybe we can hit a few stops together. I'll PM my cell number.