-

Posts

1,753 -

Joined

-

Last visited

-

Days Won

76

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Pressureangle

-

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

I'm not the guy who routes in stone, just easy to keep stops in Garmin. How about this; I can start about anywhere, let me know where you are going to be Mon/Tues, maybe we can hit a few stops together. I'll PM my cell number. -

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

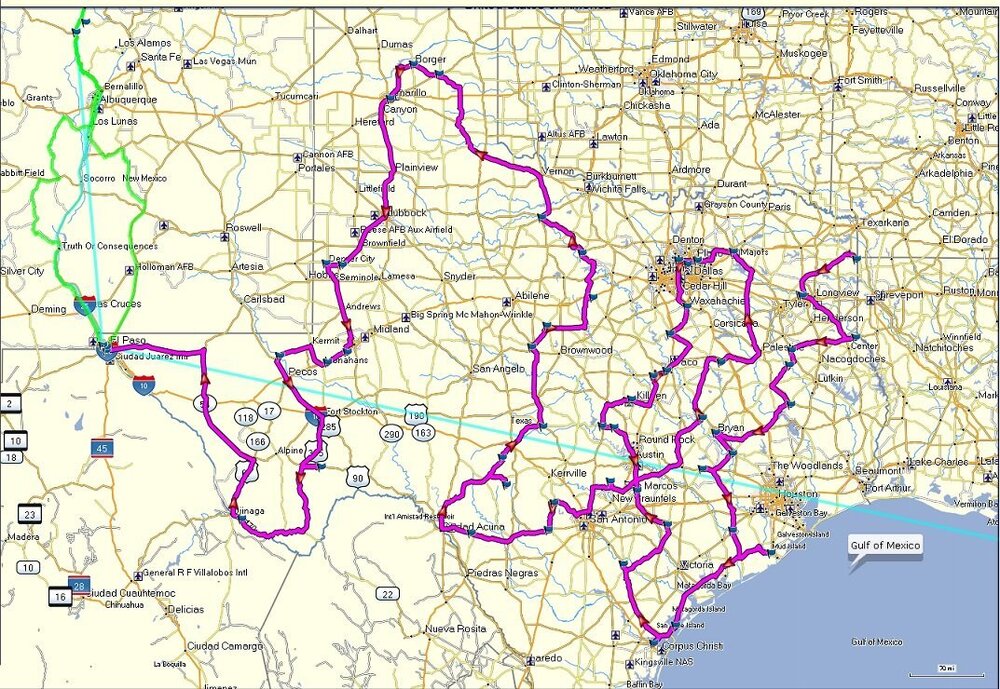

Survey says no. Candelaria is the last reach for solo riders on big bikes. Chispa road goes past but is not for tourists. Can take the Mexican side up from there, but uh...no. So I'll keep to the route on the Garmin, cutting back to Marfa. -

ANSWERED Is my Electrosport Stator Defective?

Pressureangle replied to Sam P's topic in Technical Topics

Data, yummy. Watch the charge light, with engine off turn key on and wiggle it around, see if lamp lights or flashes. Do the same while giving the harness the wiggle test at suspected connections. -

The bolts in this V11 appear to the the same size as the '97 Sport and the '85 Tonti LMIV.

-

ANSWERED Is my Electrosport Stator Defective?

Pressureangle replied to Sam P's topic in Technical Topics

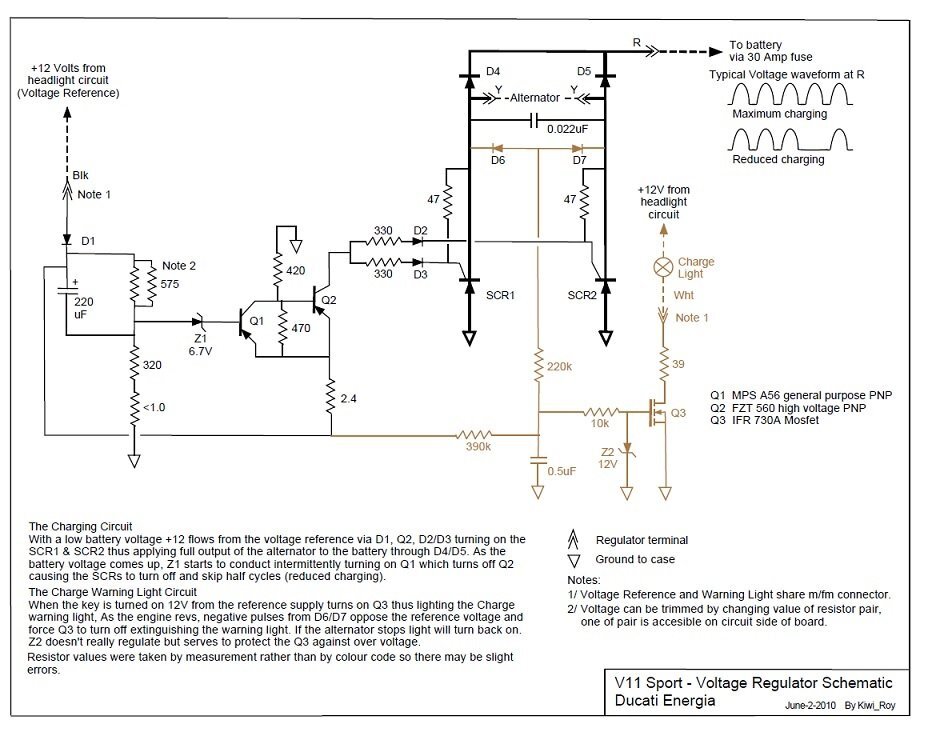

Yeah, that's where I started too, until Kiwi Roy's schematic showed up. I confused myself and the thread, but hey we're all learning together. I guess I *can* change my charge lamp to LED. -

I had a customer back in the early 90s who was head of lubrication engineering at Ashland oil. We had just started racing 883s, so of course discussed thoroughly. He said, "All oils are equal for the first 5 minutes". The extended point was that oil breakdown is more relevant to your motor than what you start with. I could write a dissertation, but here are the high points; Low viscosity oil is better for cold starts and tight clearances. Not prone to cavitation when cold. Throws off the crank more easily to lubricate cylinder walls better. High viscosity is better for high temps- because it's thinner at high temp than low viscosity at low temps. Counterintuitive, but often true. Low viscosity oils at high temperatures can burn and scuff off more easily- a situation that has little concern in watercooled engines but hugely important in air cooled engines. So while straight-weight oil is what usually finds it's way into strictly racing engines, it's because their operating conditions are stable. It was true 20-30 years ago that wider W ratings meant the oil broke down more quickly; still true, but not as quickly, and not as completely as before today's supreme quality synthetics. So viscosity breakdown (which usually means the oil thickens at low temps, rather than thins at high) happens well beyond reasonable change intervals. Since I'm in a year-round warm climate, and I rarely ride less than 100 miles at a crack, I use 15w50 Shell Rotella T6 diesel oil as my go-to if I can't source my preferred Klotz V-Twin 15w60. Rotella being a diesel oil still has anti-scuff additives that are gone from gas engine oils, but the detergent package means I change it at 5k miles where the Klotz looks good for 10k. Also, Rotella is half the price of Klotz. At the end of every oil thread, lies the fact that most engines simply don't much care what you put in them if you change it frequently enough.

-

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

No, just planning the route...I'll probably leave here this weekend and begin the tour early next week. First stop is the alt at 3 corners. Other side of State, but Q in case you know; Can I ride the border from 67 at Ojinaga all the way to El Paso? Do I need to carry more than one spare magazine? OBTW I've never ridden a Tour Glide further than a test ride after repairs. Really not my style. -

-

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

That's my tour stop #8. -

10mm bolt has an 8mm allen socket, that's likely the disconnect.

-

'coarse'

-

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

No, I would like to but it's not so. This is my first MCGTT, and my BMW Adventure needs to return to it's home in El Paso so I'm taking the opportunity to kill a few birds with one stone. And of course, the GSA carries everything for self-sufficiency. I plan to tent camp when possible. Maybe I'll ride out next September and ride you up to Tellico. I need some long days. -

My 2000 has 10mm caliper bolts.

-

Here in the US when I have to use a non-preferred oil, for a change on the road, the simplest rule is to avoid any SAE EPA rated oil. The tree huggers have taken pretty much everything out of the oil that doesn't burn in order to keep the catalytic converters active as long as possible. "Classic Car" oils, "Offroad competition", Outboard/marine 4 stroke oils and most OEM motorcycle oils still have good additive packages. I'm using 15w60 Klotz simply because it tops the charts in protection and I'm in S. Florida/Georgia and never have to worry about starting the engine below 40*F. The most important reason to use a full synthetic oil is that it stays alive in the valve guides. Natural oils coke up and wear the guides. This is critical in air-cooled engines. H-D had a huge problem with it in the early '70s, so bad the valves would actually sieze in the guides and get bent or bend pushrods.

-

ANSWERED Is my Electrosport Stator Defective?

Pressureangle replied to Sam P's topic in Technical Topics

The lamp itself can illuminate with far less than 12 volts, so the lit lite doesn't tell us the circuit voltage is good. I'm curious about the headlamp too, LEDs are internally regulated to about 5vdc so even if for instance the headlight circuit is only getting 8vdc the LEDs are still bright. I'm trying not to confuse the OP, or myself, by theorizing too much before he can catch up on physical diagnostics. -

ANSWERED Is my Electrosport Stator Defective?

Pressureangle replied to Sam P's topic in Technical Topics

So, no, the charge lamp does not 'activate' the regulator. The headlamp circuit supplies voltage to both the regulator and the charge lamp, and the internals of the regulator do in fact 'balance' the voltage to the indicator lamp. With regards to our symptoms, the lamp is a clue; it will be dark *any time* the headlamp circuit is dead...and most of the time while it's live. The only time the lamp is *supposed* to come on is when the Battery, via the HL circuit, has more voltage than the regulator is outputting. -

ANSWERED Is my Electrosport Stator Defective?

Pressureangle replied to Sam P's topic in Technical Topics

I screenshot KiwiRoy's schematic so we can see it more easily. It says clearly that the voltage reference comes from the headlamp circuit. Have to go back to see if the bulb is in that circuit or not. -

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

I can't speak to how Garmin works on my Win7 PC lol -

Motorcycle Grand Tour of Texas, 2025 edition.

Pressureangle replied to p6x's topic in Meetings, Clubs & Events

-

ANSWERED Is my Electrosport Stator Defective?

Pressureangle replied to Sam P's topic in Technical Topics

We discovered at the SSR a couple years ago that the taillight on my 'Sport would come on by itself after an hour or so. No key anywhere. Relevant to this thread, it was the ignition switch goo come to life as a capacitor. -

Was kinda my point. Probably won't crash, will in all certainty tip over in a parking lot.

-

Well, mine needs paint and has clipons.

-

Yeah baby...

-

ANSWERED Is my Electrosport Stator Defective?

Pressureangle replied to Sam P's topic in Technical Topics

Awesome. So as Phil said early, the headlight circuit is the voltage reference source, and the regulator actually uses reference to turn the lamp on and off, not a simple balancing act. So now there are 2 considerations, the reverence voltage and the delivery voltage. Easy enough to verify reference, via connectors all the way to the regulator. If the reference matches battery voltage *with key on*, then it's a delivery problem; that has 2 elements, the VR itself and the delivery circuit.