-

Posts

1,010 -

Joined

-

Last visited

-

Days Won

43

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by MartyNZ

-

Neutral shown, marks align when in first gear. Docc is right (again). I think it's best to fit the plate with the gearbox in neutral and the plate set as shown.

-

Meaning of the markings visible throught the right hand side viewport?

MartyNZ replied to p6x's topic in Technical Topics

I always make sure that I turn the engine forwards before valve adjustment too. We know the thrust washer on the forward end of the camshaft can wear on the fwd face, so the shaft is loaded aft when running. I assume this is because the cam lobes run off-center of the cam followers to rotate the followers. Turning the engine backwards may let the camshaft move forward and change the valve clearance. Also the oil pump will deprime itself so oil pressure will be slower to rise on the next start. -

What is broken? If it's the wires at the base of the sensor, then it can be fixed. I pulled Cash1000's sensor apart, and dug out the resin potting compound to expose 2 terminals in the base. I crimped copper sleeves over the terminals & shortened wires (they were too long anyway) then repotted the cavity with epoxy.

-

The factory spring might last that long, but you can be certain that it will break eventually. Chuck did the calculations on the factory spring and determined that it was poorly designed. It needed to have another turn in the loops. Otherwise, in normal operation, the spring wire deflection exceeds the elastic limit, going into plastic deformation (the permanent set). Then metal fatigue is followed by breakage, followed by a trip home in 2nd gear. 😟 A picture showing the 2 versions of the springs are shown in the link below. https://www.v11lemans.com/forums/topic/20201-re-engineering-the-shift-spring/?do=findComment&comment=272760

-

Getting back on a V11. Things I should know.

MartyNZ replied to DucatiGuzziIndian's topic in 24/7 V11

All your questions are well founded, except the one about tires. Like oil, there's lots of good choices, everyone has a different favorite, and trying to get consensus is a lost cause. This site offers answers to all the other questions, but searching inside the site can be tedious. I've had good luck using Google and "V11lemans.com" plus your topic. As for answers, I'll take the one about relay bases. Two things can go wrong, there's a plug hidden under the base that can come loose, and the terminal sockets in the bases can slacken due to frequent relay changes. See @Kiwi_Roy s post -

Both sides spark plugs are black; looks like my mixture is too rich!

MartyNZ replied to p6x's topic in Technical Topics

Which plugs are from the lower cylinders? I thought that those could have more oil fouling, but there doesn't seem to be any sign of that. Your oil scavenge system must be good. I've never been able to reach firm conclusions looking at plugs. It seems that they look different depending on whether they were removed after a long taxi at idle, or a cut from power. If it was an idle fuel cutoff, then my opinion is the RH plug was running a bit lean. Unleaded gas always makes the plugs look a bit darker than leaded avgas; what do you use? -

Have you read this? https://www.v11lemans.com/forums/topic/20772-ram-clutch/page/2/#elControls_238925_menu And this: https://www.v11lemans.com/forums/topic/21247-scura-single-plate-clutch/#elControls_242019_menu

-

I fitted Aprilia disks to my bike after the original disks wore below limits. Part number: AP8133781, Brand: Sunstar. "Vespa APC Aprilia Derbi Gilera Piaggio Scarabeo genuine spare parts" written on packaging. https://www.v11lemans.com/forums/topic/23922-encyclopedia-of-compatible-parts/?do=findComment&comment=231694

-

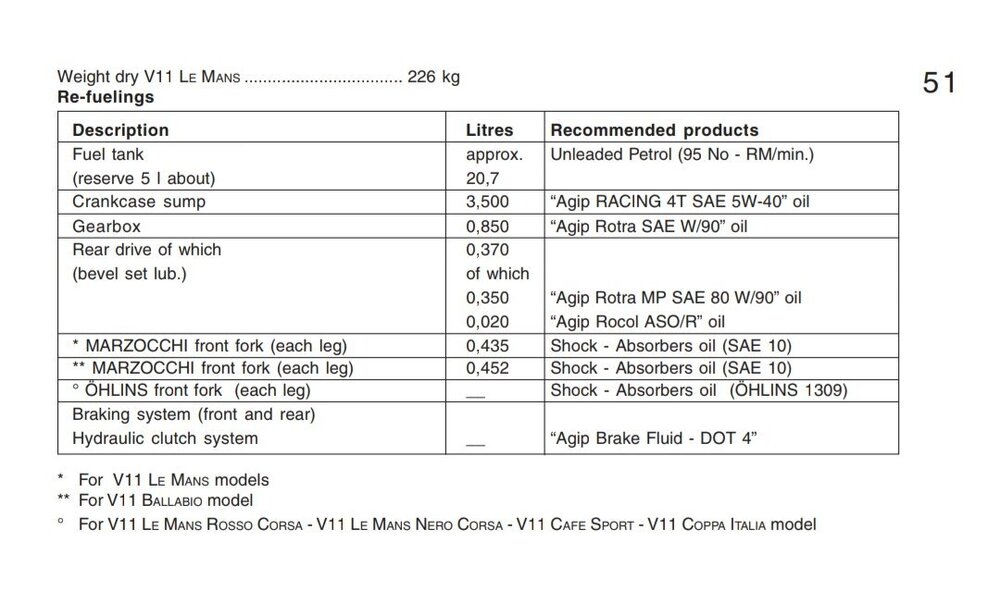

Bridgestone says "The "GT Spec" is for heavy weight vehicles" and "can be installed not only on large tourer vehicles but also on medium vehicles around 250kg". Do you think that the T32 GT spec is better than the standard T32? It does sound hi-zoot, but I ask as the V11 dry weight is around 220kg. I'm looking to replace the Battlax BT023s on my bike.

-

I use Power Punch EP1. I bought a bottle from Moto International while they were still open. It will outlast me, even with @cash1000 using it too. You can buy it here: https://www.powerpunchinc.com/Gear_Oil_p/ep1-each.htm I imagine that it is specified due to lower speed than the gearbox, but higher loads and sliding tooth contact. Docc's use of Redline Shockproof probably makes moly unnecessary.

-

Mistral and Termignoni made aftermarket crossovers for the 1100. Picture is Termignoni

-

We know that it's important to have the rear wheel spacer stack-up right, or bearing life will be short. It's difficult visualize the parts that make up the stack-up, so I marked up manual pages in the attachment to show the parts involved in clamping the inner races of each bearing. Sizes are included. The sizes are my measurements, so if you have any comments, then I can edit the pages. V11 Rear Wheel Spacers v1.pdf

-

Yeh, sorry Docc. I meant isopropyl alcohol, or any mild solvent. Using your IPA would be wasted.

-

My old sensor leaked just enough to bother me. It appeared to be through the sensor, not around the o-ring. I washed it in IPA, & heated it over 100°C with a heat gun a few times. While it was hot I brushed epoxy resin all over the sensor and blew the excess off with the heat gun & a rag. As it cooled, some resin wicked into crevices in the sensor. It seemed to work. As for putting any gasket goo on an o-ring, I believe that's a bad idea. One or other is fine, but if the sealant doesn't stick to the o-ring, then you have added another leak path, and inhibited the O-ring's ability to keep sealing with thermal movement.

-

ANSWERED Front driveshaft protection collars: no differences

MartyNZ replied to docc's topic in Technical Topics

64.2 ish mm front collar on my long frame 2003. -

ANSWERED Front driveshaft protection collars: no differences

MartyNZ replied to docc's topic in Technical Topics

ID 65.8mm on 2003 model rear collar -

ANSWERED Front driveshaft protection collars: no differences

MartyNZ replied to docc's topic in Technical Topics

I have a spare rear one you can have if you want it. I made one out of aluminum alloy for the bevel box on my bike. -

The wiring looms under the airbox don't have much room, so check before you finalize tidying. My bike toolkit has a 14mm hex about 25mm long that fits in both f&r axles.

-

In different parts of the world, octane is measured differently. In NZ the octane reported at the pump is the RON value only. In the US, octane is calculated as (RON + MON)/2. 100 octane in NZ would be somewhere around 95 octane in the US. I wonder what the Moto Guzzi V11 fuel recommendation refers to? RON or (RON + MON)/2? I tried 100 RON and as @Lucky Phil said, it made no difference, so was wasted money. However, Avgas is different. When I was a young apprentice, I "salvaged" a 25litre drum of 100/130 (green Avgas) from a DC3 going into maintenance and put it in my Honda CB450. It felt faster, so I tested it. It reached 1000rpm more in top gear at the bend on Harewood Road on 100/130 than the "96 Super" of the time. I previously thought that higher octane was only worthwhile with higher compression or a blower, but there it was going faster. Obviously there was some other difference than just octane rating for this fuel to give noticably more power. I had just fitted new 1st oversize pistons and rings, and XS650 cans, but otherwise the 450 was standard. I know that Avgas has less volatiles to avoid boil-off and vapor lock at altitude, and I assume higher calorific value ingredients which made such a noticeable difference.

-

Docc, I think he means something like "you're technically correct but meh, does it really matter?" A bit like the susceptibility of titanium to embrittlement & stress cracking when in contact with cadmium; it's true, but at normal temperatures it isn't very important.

-

Wow that's a good weight saving. What titanium alloy did you use?

-

Just a comment about using a white LED behind a green dash panel lens. I believe that you would get a brighter and more noticeable dash indication if you use a green LED instead of white. A green lens filters out all visible light except green. Only green can pass through, and the rest is absorbed. So, all the light from a green LED passes through the lens with no loss, because it is only green emission. LEDs have a very narrow light emission spectrum (except white LEDs). Your white LEDs are most likely blue or UV LEDs with a phosphor over the emitter surface which glows (sort of bluish) white. Then only some of this white light can pass through the lens, assuming that the bluish white light has some green component to its output. There are two losses in this. 1/ Blue to white conversion inside the LED, and 2/ white filtered by the dash panel lens, to leave only green. This means that a white LED will be dim compared to a green LED when viewed through a green dashboard lens. The same logic applies to red taillight LEDs (better than white LEDs), and amber indicator lights (better than white LEDs). EDIT If those white superbrights are bright enough when installed, then ignore what I wrote above.

-

I filed off a lot of the encapsulating resin of square LEDs to make them fit.