-

Posts

1,753 -

Joined

-

Last visited

-

Days Won

76

Content Type

Profiles

Forums

Events

Gallery

Community Map

Everything posted by Pressureangle

-

My experience is that visibility is quite often better. I much prefer the parking lot panache, too. All the cool kids have bar end mirrors. But my bike has been on the ground about $600 worth of bar end mirrors, so I won't be having any myself. On the last point, why aren't we all riding Sportsters? Or wait...

-

I think I figured out the whyfor on this adjustment. I figure it's insurance in case the pawl doesn't fall all the way down on a shift- if the pawl hook is hanging on the pin just enough to pull the wheel it will roll up and off as the wheel turns. When it crosses this adjuster it will be forced down as it passes, so the hook can't jump off the pin mid-shift. Not having one, I can't know how to set it, but I guess I'd set it with a couple to a few thousandths at the closest point that passes during normal operation. Is the adjustment spec in the service manual anywhere?

-

Today's labors was parcel tidbits. Roller berrin for shift detent- niiiice Pawl alignment- niiice Pivot pin nuts... uh... very, very nice says the price. Shame about the background at the moment. Don't forget, kids, do your pawl adjustment in the vice or do it twice. Now waiting for seals and pawl adjuster locknuts.

-

The Most Beautiful Cafe Racer Yet?

Pressureangle replied to Joe's topic in Special place for banter and conversation

Very pretty. I'm not allowed to own things so clean. The color is very near to the stock color on my '70 Norton Fastback, 'Fireflake Golden Bronze' though it looks like what I'd call 'Orange'. -

Given what I've posted above about adjustment, and if it's not too late, I'd be interested in knowing how your pawl is adjusted. Mine was so far out the pawl wouldn't fall over the pin upon release, certainly causing failed shifts though I'm not certain in which direction.

-

Not as easy as it sounds. Hmph. https://belmetric.com/acorn-nut-stainless-fine-thread-din-1587/?sku=NA12X1.25SS

-

Ok in reply to my redacted embarassment above, let's go through shift adjustment. Which even the early doors have. The point of the adjustment is to have the pawl evenly spaced in both directions over the pins. This is accomplished with the external flat-headed screwbolt next to the shift shaft. As stated elsewhere and many times, this is not an adjustment you can do correctly on the bike, there is very little latitude outside of 'correct'. The screw can be installed with the eccentric either up or down, but beginning with the eccentric 'down' or farthest from the shift shaft gives the least sensitivity to the adjustment. The adjustment itself is very fine, the entire range of success about 1/16th of a turn so you need 1/32nd of a turn accuracy. I've tried to show and represent the goal and pieces as clearly as possible. As for actually measuring the travel in both directions, you could set up in a vise, with calipers, and an extra set of hands to measure exactly but your eyes are calibrated sufficiently to move the shift plate back and forth to feel the pins in the pawl. Be sure to mark the slot in the screw before tightening the locknut to be sure it doesn't move while you tighten. If your cap nut looks like mine, get a shiny new one. Edit; don't even bother alone, without a vice. It isn't that easy. A magnetic dial indicator to tip the end of the pawl would be the cat's meow.

-

Er...somebody tell me what this 'adjuster' adjusts? It looks like a backstop for the pawl arm, where mine has a roll pin. The external adjuster on the newer style doors adjusts the center spring perch under the shaft plate, yes? Edit; I get to look stupid. My own door does have a centering adjustment-which obviously was not adjusted. Must be failure to verify, lack of sleep and the 98* garage. I still need someone to explain the 'backstop' adjuster as I don't see a purpose for it. Maybe it'll come to me in a dream. Sheesh. All for naught. Oh, and apologize to MG.

-

My son was going to take the 2000 as a 'tourer'. I told him that if he wanted one to keep forever and outfit for travel, this would be the one. I've bid on it.

-

ANSWERED Pesky single plate clutch/flywheel!

Pressureangle replied to pete roper's topic in Technical Topics

Decided against the RAM, in the interest of both time and economy. But one never knows what's up the road. -

ANSWERED Pesky single plate clutch/flywheel!

Pressureangle replied to pete roper's topic in Technical Topics

My crank and flywheel bolts all have Schnorr washers. Looks like a trip to Harbor Freight for some rust remover. -

ANSWERED Pesky single plate clutch/flywheel!

Pressureangle replied to pete roper's topic in Technical Topics

-

"perfectly usable, but not perfect" That's a perfect and perfectly usable description of this entire motorcycle. I can hand-file it, hammer it, and paint it into the shadows. We can have form tools made easily enough and have the press to use it in. As with the Roper Plates, the demand at this point is dwindly but hobbies don't run on profit, and we do have an apprentice to teach all the old ways. So if and when you happen across it, toss it my way and I'll add it to the pile.

-

Just remembered I have a WP front end from a mid-90's Buell...

-

K...my 2000 has this shift lever...is this factory, with 2 holes? If so, is the top hole still 12mm shorter than Chuck's? Chuck, do you still have any of these? ... and if not, do you have the file and form tool to make them with? I could add them to the slowly growing pile of have-nots we can make without much pain.

-

Suspension Upgrades. Talk to me

-

I got a $750 V11 and the Staintunes are on the shelf lol I will be certain they don't fit the 1100 Sport before they're fitted to the V11, though.

-

My take on BaT is that it's mostly a bunch of whiny rich-adjacent cheapskates. On one side are people fishing high prices, the other side douchebags trying to submarine the item to bring the price down to where they can afford it, or sour grapes it because they can't. Change my mind.

-

The loudest clutch I've ever heard is in my '74 Aermacchi/HD Sprint 350 after venting the clutch cover.

-

Well...to be fair, could have been my badly angled wrists leaning over the tools I should have put away while the lift is at full height.

-

ANSWERED Pesky single plate clutch/flywheel!

Pressureangle replied to pete roper's topic in Technical Topics

Got an official Pete Roper slosh plate? -

ANSWERED Pesky single plate clutch/flywheel!

Pressureangle replied to pete roper's topic in Technical Topics

Harpermoto.com has everything, at least they had everything I needed sealwise from rear main to output shaft, within the week. https://harpermoto.com/collections/2002-v-11-le-mans-1100-transmission-cage -

I'm rehabilitating a 2000 V11 Sport I got for $750- to make it look that nice and recover the 64k miles it has on it, would cost as much as you're asking. Maybe more depending on the price of paint.

-

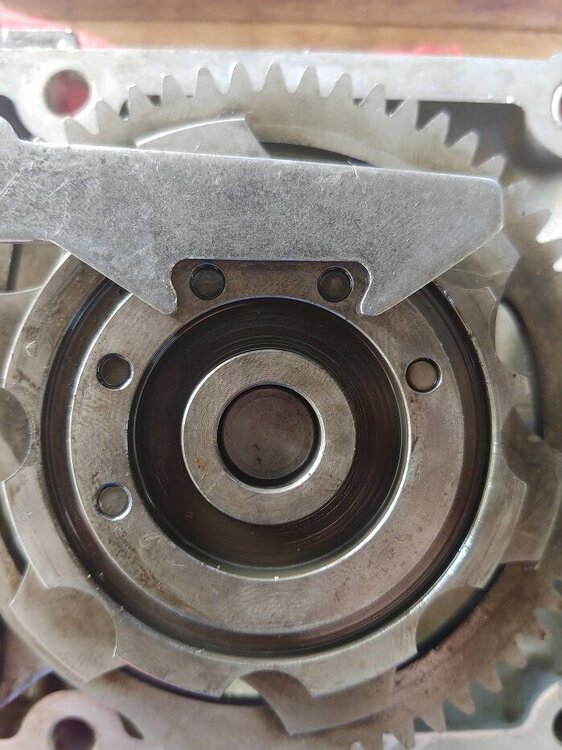

So, bearing race came off, with a little learning curve on the new inductive heater- it comes with an insulating wrap specifically for bearing races. It doesn't say why, other than that the coil used for races isn't preformed and I assume it is so you can use it on any size, and the insulator keeps the coil cover from burning. With 3 wraps and the insulator, I had to go back 4 times, the last time being for 25 seconds plus whatever heat was in it beforehand. Here's what it looks like apart, with everything in order of assembly (the compensator ramp and gear in the case simply slide apart as well) The bearing in question is on the right, trapped by everything between it and the end race on the left.

-

Since it's right at hand, my 2000 v11 bodies are (actual) 44.68mm vertical and 44.71mm horizontal at the inlet.