Leaderboard

Popular Content

Showing content with the highest reputation on 08/15/2025 in all areas

-

With a few more measurements, I could send that up for quotes to the same supplier making the Roper Plates. I may just do that when I get around to sniffing the butt of this zombie bike.2 points

-

2 points

-

Getting ready for a ride to the Appalachians in a month and found a weak rear Pirelli GT. They are lasting about 3500 miles for me; right at average for my 30 rear tires. (I get 3 rear : 4 front). Trying to follow my own advice (Wheels Off Maintenance Checklist in FAQ) , I found my Brembo rear pads ready for a change (10,111 miles/ 16.300 km). Inboard more than outboard, which tells me the pistons need cleaned, equalized, pin polished and lubed, and fluid bled. The brake side rear wheel bearing was also played up. Fourth one on that side. Only the third on the drive side, which felt okay, but my trusted friend, Josh, who found the bad bearing says, "Change them both." I believe in this guy! The last bearings were made in China and lasted 1/2 as long as the OEM, Euro-made stuff. I'm trying to source better made bearings. So . . . when that tire needs changed, folks: Wheels Off Maintenance Checklist!1 point

-

Docc- This would fit perfectly in your collection between the GB500 & V11 Sport….1 point

-

1 point

-

this was from a parts bike I had. Hand made. This is stainless so not an easy shop fab, but maybe useful for you to come up with something if you don't find anything. it's made from flat stock and bent. I made a template for future needs. This lighting is ebay. You can make flat portions larger for different lights. the lower bit is just thin aluminum cut to cover the exposed wiring and such under the tail. It all bolts to the existing subframe wiith no mods. Click the pics to enlarge. Hosted on https://imgzeit.com/1 point

-

1 point

-

A too-long spacer won't put side pressure on the bearings, so no- probably. You can, if the spacer is too long, drive the bearing outer races into a tight hub where they can't center themselves- achieving the same effect, though the axle nut can apply a lot more pressure than likely to achieve by driving them against the spacer. Phil's method above works, and if you have a nice hardened (read 'measures consistent across surfaces') washer, you could probably just rotate the washer by hand on the spacer and installed bearing, and feel it kinda just brush against the race shoulder. If the washer is hard against the hub, the axle nut will crush any clearance out- too tight. If it measures good and feels good, you're good. "In the event this 112.9mm measurement is reasonably accurate, and my replacement spacer is 113.145, then may spacer is too long by almost 0.010" (0.245mm). Based on the discussion, that sounds like too much lateral displacement of the inner race limiting the bearing life?" I'd like to see less than .010", but I wouldn't let it keep me from riding.1 point

-

1 point

-

I mentioned in my previous post the technique for those without machine shop equipment. If you haven't got the money for a $50 set of 6 inch verniers that will last you for life then you probably shouldn't be working on you bike to start with. I've never had a wheel bearing that was a "tap fit" in a hub that wasn't damaged in some way. Thats why they are usually C3 bearings standard. Every one I've ever done on an undamaged hub required enough hammering on the inner race during removal to make it unusable again. Unusable in the sense that it will have reduced life by quite a margin. It is still of course "useable" in the sense you can fit it and ride around for a while but long after you've forgotten how you hammered it you'll be wondering why it's life was far shorter than you expected. Phil1 point

-

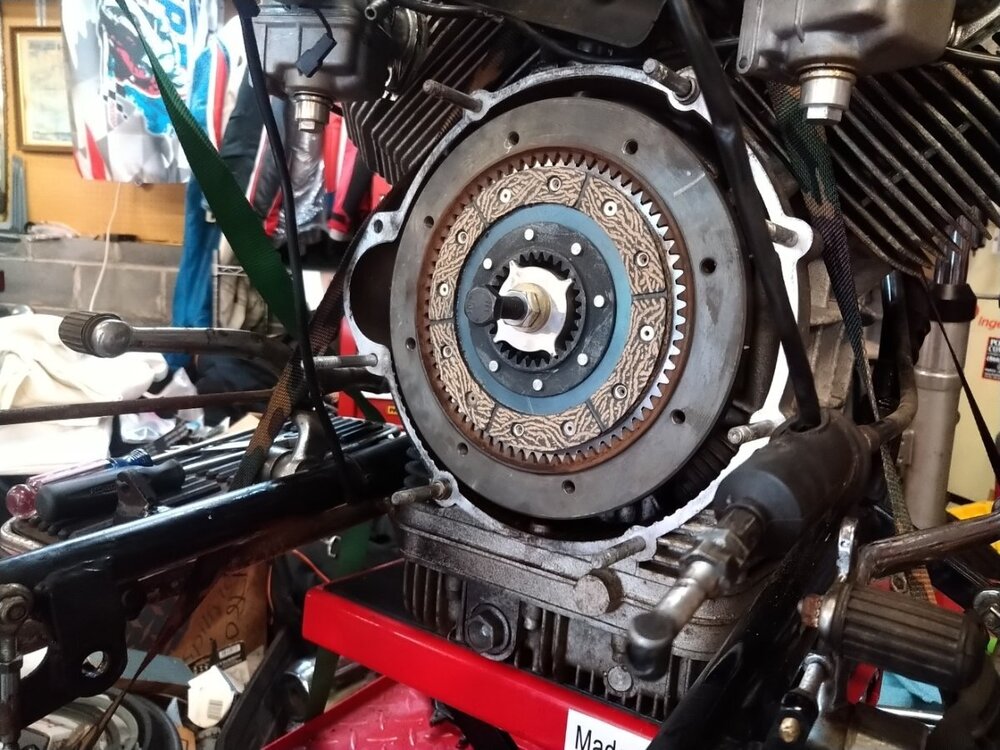

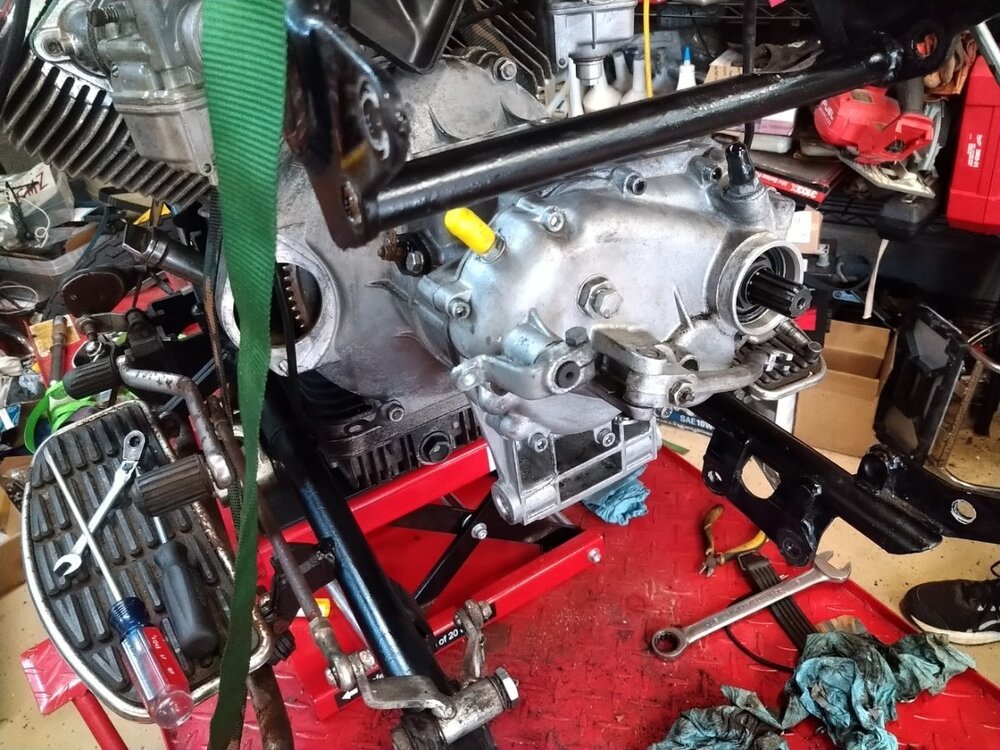

Parts came in yesterday, so back on the project. It took some effort to split the clutch discs from the intermediate plate, but they look really good, so spare parts. Installed the new clutch, new throttle cables, transmission seals, rear main seal, float valve, breather hoses, air filter, etc. The swingarm and the center stand were PITA, but they are on now. Hopefully more work tomorrow.1 point

-

as long as you're in there, here's how I verify spacer fit- Set both bearings tight to the hub shoulders, with no center spacer Measure bearing depths from hub flange, both inner and outer races Remove one side bearing, place spacer. Re-install bearing until it bottoms Re-measure bearings; if you have *zero* change from no spacer measures, it's too short. If driving the second bearing home changes the depth of the first bearing, note by how much. These small bearings have very little clearance, so I would say if your center (spacer) race moved by .001" to .003" you're in good shape. If you get more protrusion than a couple thousandths, your spacer is long- which can overload the bearings if the outer races are too tight to float in the hub, which they should be. I would rather shim up a short spacer than try to work with a long one, as it's important to have the ends perfectly square to the centerline of the bearings, hard to achieve with a file or stone. If your spacer is long, you *can* drive the bearings against the spacer with an appropriate driver that touches only the inner race- then when the driven bearing finds home, the direction of forces on both bearings will load the races equally and center themselves up. That does leave you with a couple or few thousandths between the hub and the outer race of one of the bearings; a few thousandths is ok, but if they aren't tight in the hub they can shift and chafe during use. Have I overclarified that to mud now?1 point

-

Absolutely agree. I'd personally much rather tour the crumbly prewar edifice, myself. However, in the big Corporate picture, the vast majority of persons want Disneyworld. So there has to be some poop to attract the flies. I'd rather see them build a tourist destination and with it a solid customer base than to see them struggle with viability.1 point

-

I completely agree to that. There is much more charm in authenticity. We are not alone in this preference. It is becoming a bit of a problem in Europe, a writer overhere wrote a book, "Grand Hotel Europe", where he explains the controversy of tourism to authentic places. Interesting for me to read that in fact I am also part of the problem.1 point

-

Not that I know of docc. He may have bought some stuff but TLM bought a large amount. He's more of a remanufacturer of parts but Audiomick would know more than me. I won't deal with HMB anymore. Phil1 point

-

I saw the new factory under construction when I was in Mandello last September. It looks interesting BUT it's obviously going to be a another "tourist attraction" thing. Don't know about others but the interest for me these days is to discover things and places that aren't popular or "attractions" for the masses. Things like the back alleys and little side lanes in Venice away from the main attractions where the real Venice life is or the hills of Tuscany and the Villas and small villages away from the hustle and bustle of the cities. Bit like going to an old world bike shop with an owner and staff that have been running the place for 50 years. Much more interesting than the modern glitzy places of today inhabited by people that seem to think you are privileged to be in their showroom. Phil1 point

-

https://www.mgcycle.com/index.php?main_page=product_info&cPath=37_156&products_id=831 point

-

I'm reintroducing myself to this forum. I was on it around 2004 or so when I owned a V11 Ballabio. I sold that bike to help with the down payment on a house. Since then I've had several bikes mostly Ducatis including a black 2005 999S. At 69 y.o. that bike, although I loved it dearly, was just not working for me at this time of my life. I sold the 999S and had always wanted a V11 Le Mans. I searched around for a really nice example and located this stunning 14,000 mile 2002. Rode it home from Sonora via hwy 49, one of my favorites. Looking forward to re-joining the group.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Probably better in "How to . . . " which allows for replies, whereas FAQ does not. I've seen @footgoose's Tenni in person and that tail is tidy, indeed. Combined with the way he groomed the Titanium exhaust, the the entire back of the bike is transformed. Well, certainly compared to mySport that looks like it's carrying a tarped-down high and heavy load . . .1 point

-

This looks reasonably DIY "doable" @docc We should consider putting it in the FAQ section since the options available never were very common even when the V11 was new, and now are dwindling if any are even available anymore commercially.1 point

-

I went ahead and installed one bearing so that I could measure the length that my spacer would need to be. Sure enough, it needs to be .014 inches longer to not bind. So my new bearings would have had a shortened life. I’ll get some .015 shim stock and make a shim.1 point

-

1 point

-

1 point

-

From Google: Currently, SKF China has 18 manufacturing sites in China (including PEER), with products ranging from various types of bearings, seals, lubricants and mechatronic products, etc. Our Manufacturers - SKF.com https://www.skf.com/cn/en/our-company/SKF-in-china/Our-Factories/index.html ======================== Food for thought...1 point

-

When my drive side rear wheel bearing failed I found the bearing spacer was too short so I shimmed it to stop it loading the bearing. I did however notice that the bearings felt a little tight when installed and I postulated about fitting bearings with more radial clearance. ciao1 point

-

When things drop, that you are not expecting, they can get lost. So as you haven't done this before, a very small addition is to watch out for the big 'penny' washers when you take the bolt out at the rear of the tank. They are liable to fall when you lift the tank. If you have a nice clean, tidy garage to work in, that won't matter – but just in case... As well as the electrical connections, I grease that bolt and the washers to keep long term corrosion at bay. You might as well, while you are at it.1 point